Welcome!

Deoxidizing agent-Screen translation

Basic Info

| Product advantage | It can increase the temperature in the furnace, shorten the melting time, increase the output of steel, increase carbon, deoxidize, add silicon and raise the temperature, and can also be used as a substitute for ferrosilicon. In addition, no dust pollution is generated in the furnace throwing process, the reaction speed is fast, and the cost is reduced. | Silicon content | 50/55/60/65 | granularity | 10*50mm |

|---|

Product Description

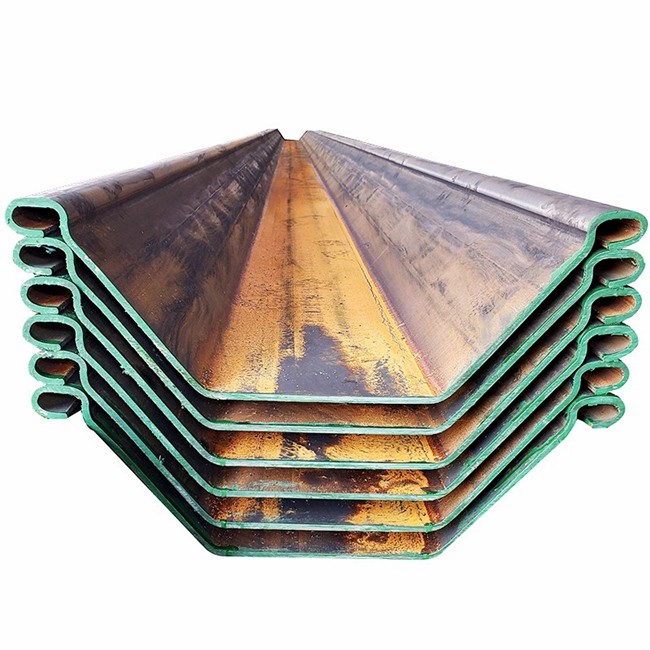

Our factory produces steel-making deoxidizer-silicon carbide balls, and the main

production models are: 50 # 55 # 60 # 65 # 70 # and other models. The monthly

output is 3000 tons, and we look forward to cooperating with you.

Silicon carbide balls are mainly used in electric furnaces and cupola, as

deoxidizers, and in casting and steelmaking industries. It can increase the

temperature in the furnace, shorten the melting time, increase the output of

steel, increase carbon, deoxidize, add silicon and raise the temperature, and

can also be used as a substitute for ferrosilicon. In addition, it will not

produce dust pollution during furnace throwing, and the reaction speed is fast

and the cost is reduced, which is a new way in the steelmaking process.

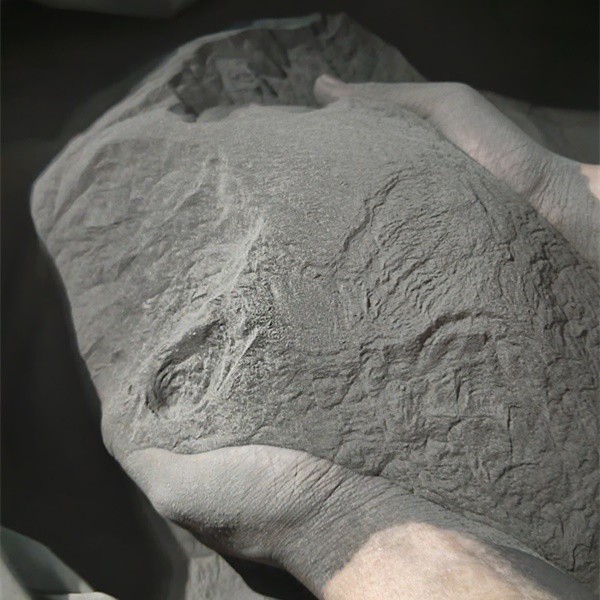

The advantages of using silicon carbide balls are as follows: 1. Useful metal

oxides are reduced to be absorbed in steel, which reduces the loss of molten

steel and improves the output; 2. The reaction heat energy generated when the

silicon carbide element is oxidized can reduce the electricity consumption and

shorten the operation time. Production technology: crushing/grinding/ball

pressing product use: black silicon carbide ball is a new type of composite

deoxidizer, which is widely used in steelmaking and ironmaking industries.

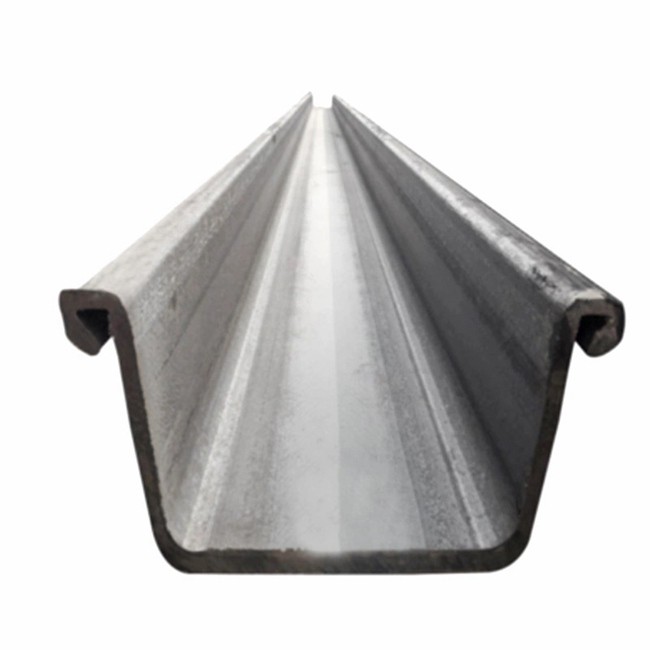

1. chemical content brand Plate chemical composition (%)

sic free c si+sio2sic55

55.0-57.0 4.8 1.5 28 3

sic60 60.0-63.0 3.5 1 25

2sic65 65.0-68.0 4.5 1 23 22.

particle size: 10-50 mm.

Recommended Products

Recently Viewed

Contact Us

Henan Zhixin Chuang Metallurgical Material Co. ,