Welcome!

New Design Boxes Sealing and Cutting Machine Film Wrapping Machine

Product Description

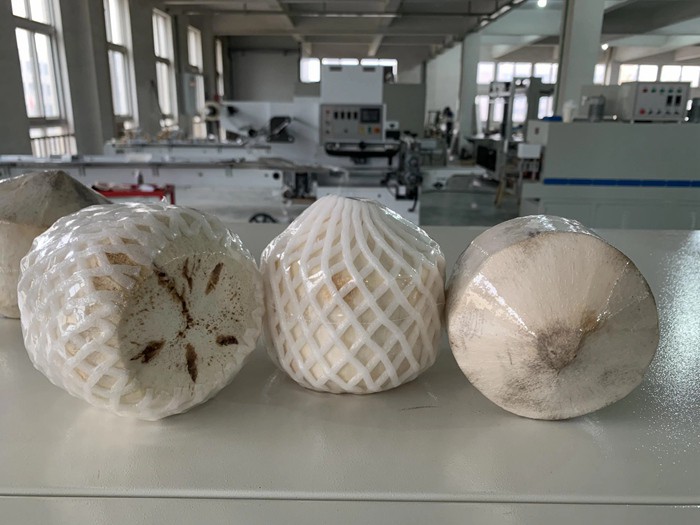

The working principle of the sealing and cutting machine is relatively simple and efficient. When working, place the materials to be packaged on the conveyor belt of the equipment, and as the conveyor belt moves, the materials are sent into the cutting and sealing area. In this area, the sealing and cutting machine uses cutting tools and pressure devices to cut the packaging material, and seals the opening of the packaging material by heating or cold pressing. Throughout the entire process, the sealing and cutting machine achieves automated operation through an advanced control system, ensuring the accuracy and stability of cutting and sealing.

The sealing machine relies on the sealing mechanism to complete the sealing work, and ensures the stability and reliability of the sealing quality by adjusting the sealing temperature, pressure, and time. The sealing and cutting machine adopts fully automatic unmanned operation, with high work efficiency, suitable for mass production and packaging flow operations. Sealing and cutting machines are widely used in packaging processes that require sealing, such as sealing plastic bags, composite films, and other materials. Sealing and cutting machines are also commonly used to produce packaging forms such as heat shrink films and vacuum bags to meet the packaging needs of different products.

The sealing and cutting machine is mainly used for sealing packaging materials. Usually used in conjunction with packaging machines, after the packaging material is wrapped, the opening of the packaging material is sealed by heat sealing or cold sealing to ensure the sealing and safety of the product. The sealing and cutting machine can automatically feed film for punching, automatically cover film for sealing and cutting, and automatically roll up waste materials. It only requires manual adjustment of the film guide system and feeding conveyor platform, and is suitable for products of different widths and heights.

The structure of a sealing and cutting machine is relatively simple, generally consisting of a base, frame, cutting tool, motor, reducer, stroke controller, and hydraulic system. Among them, the base and frame mainly play a supporting role, while the cutting tool is driven by motors and reducers to complete cutting and processing work, and the stroke controller controls the movement trajectory and speed of the cutting tool.

Sealing and cutting machine is a fully automated and unmanned packaging machine that plays an important role in manufacturing, processing, and production processes. Sealing and cutting machines are mainly used to cut, seal, process, and manufacture various materials, products, or items, especially suitable for mass production packaging assembly line operations. It is the preferred equipment for product sealing, cutting, heat shrink packaging, and can be used in conjunction with automated packaging assembly lines.

Recommended Products

Recently Viewed

Paper Box Bundling Machine: Streamlined Packaging Efficiency

Paper Box Bundling Machine: Streamlined Packaging Efficiency Advanced Paper Box Bundling Machine: Smart Automation for Modern Packaging

Advanced Paper Box Bundling Machine: Smart Automation for Modern Packaging Auxiliary Packaging Machines: Your Partner in Smarter, Faster, and Greener Production

Auxiliary Packaging Machines: Your Partner in Smarter, Faster, and Greener Production Auxiliary Packaging Machines: Streamlining Efficiency and Precision

Auxiliary Packaging Machines: Streamlining Efficiency and Precision Auxiliary Packaging Machines: Precision, Efficiency, and Seamless Integration

Auxiliary Packaging Machines: Precision, Efficiency, and Seamless Integration

Contact Us

FOSHAN UPPER MACHINERY EQUIPMENT CO., LTD.