Welcome!

Interpret The Production Process and Advantageous Applications of Microfiber Leather

Basic Info

| Color | Customized | Delivery Time | Yes | Feature | Abrasion Resistant, Soft, Elastic, Anti-Mildew |

|---|---|---|---|---|---|

| HS Code | 53091020 | Hand Feeling | Elastic, Soft, Smooth, Genuine Leather, Skin-Feel | Material | PU |

| OEM & ODM | Available | Origin | China | Pattern | Embossed |

| Production Capacity | 170000 Meters/Day | Specification | 30-50 Meters Per Roll | Width | 54/55" |

Product Description

In the evolving landscape of modern materials, a sophisticated contender is redefining expectations for synthetic leather. Microfiber leather, often hailed as the pinnacle of non-woven fabrics, represents a significant leap beyond conventional options. It is engineered not merely to imitate genuine leather but to surpass it in several key performance areas, offering a unique combination of luxury, resilience, and environmental consciousness. This advanced material is increasingly becoming the preferred choice for designers, manufacturers, and consumers who refuse to compromise between quality, durability, and ethical values. Let's explore what makes microfiber leather a standout solution for a wide array of applications.

What is Microfiber Leather and How is it Made?

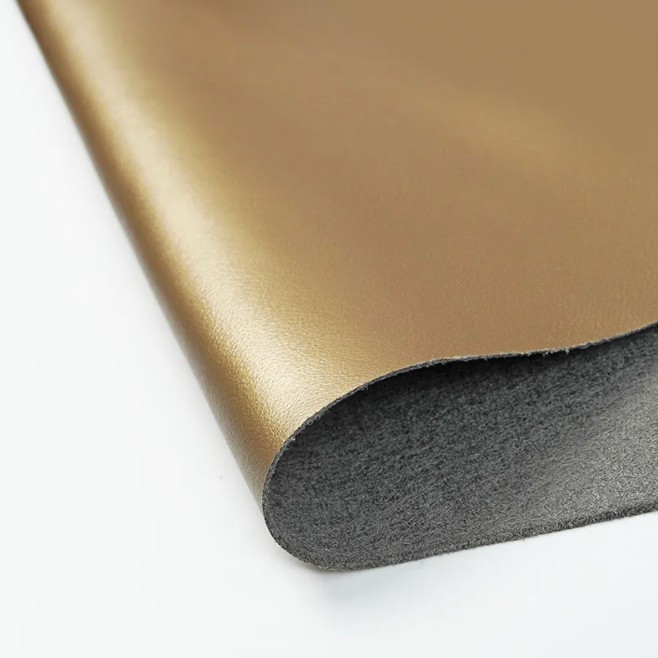

Microfiber leather is a high-performance synthetic material composed of an ultra-fine non-woven polyester web, combined with a durable and flexible polymer, most commonly a high-quality polyurethane. The manufacturing process is a testament to precision engineering. It begins with the creation of a dense, breathable base layer from incredibly fine polyester microfibers, which are entangled to form a strong, uniform substrate that closely mimics the fibrous structure of animal hide. This base is then impregnated and coated with a specially formulated polyurethane solution. The final, crucial step involves surface treatment, where advanced grain-printing techniques are used to create a texture and appearance that is virtually indistinguishable from high-grade genuine leather. The result is a consistent, high-performance material with its own superior set of properties.

Defining Characteristics: The Hallmarks of Superiority

Several intrinsic properties establish microfiber leather as a premium material. Its most notable feature is its exceptional tensile strength and tear resistance. The dense non-woven fiber base creates a robust internal structure, granting it remarkable durability that often exceeds that of many genuine leathers. Complementing this strength is its outstanding abrasion resistance, allowing it to withstand significant wear and friction over prolonged periods without showing signs of scuffing or peeling.

Furthermore, microfiber leather exhibits a soft, supple hand-feel that remains consistent across production batches, free from the natural imperfections found in animal hides. It also possesses a high level of breathability, a distinct advantage over many solid-layer synthetic alternatives. The microscopic pores within the material allow air to pass through, enhancing comfort in applications like upholstery and footwear. Finally, it demonstrates excellent color fastness and resistance to stains, ensuring that products maintain their aesthetic appeal with minimal maintenance.

Tangible Advantages: Why Make the Switch?

The technical features of microfiber leather translate into compelling real-world benefits. For brands and consumers alike, its superior durability directly correlates with a longer product lifespan, reducing waste and the frequency of replacement. This longevity, combined with a typically lower cost than premium genuine leather, offers significant value, making high-quality, leather-like goods more accessible.

From an ethical standpoint, microfiber leather provides a sophisticated, high-quality vegan alternative that does not rely on animal husbandry. Its production process is also more controllable and generates less heavy metal pollution compared to traditional chrome tanning used for animal hides. For manufacturers, the material's uniformity is a major logistical advantage. It comes in large, consistent rolls without natural defects, which optimizes the cutting process, minimizes waste, and streamlines production planning.

Versatile Applications: Where Innovation Meets Design

The unique property set of microfiber leather makes it suitable for a diverse range of demanding industries. In the automotive sector, it is extensively used for high-end upholstery on seats, steering wheels, and dashboards, prized for its durability, UV resistance, and comfortable feel. The furniture and interior design market utilizes it for residential and commercial upholstery, where its ability to withstand daily use while maintaining its appearance is highly valued.

The fashion and accessories industry embraces microfiber leather for crafting stylish and long-lasting footwear, handbags, wallets, and belts. Its consistent quality allows for intricate designs and reliable performance. Additionally, it is a popular material for sports equipment, such as gloves and ball covers, as well as for high-quality personal electronics cases and covers, offering both protection and a premium aesthetic.

Clearing the Air: Your Microfiber Leather Questions Answered

1. How does microfiber leather differ from standard PU leather?

While both may use a polyurethane coating, the key difference lies in the base layer. Standard PU leather often uses a simple knit or woven fabric backing, whereas microfiber leather features a dense, non-woven web of ultra-fine polyester fibers. This creates a more robust, breathable, and leather-like internal structure, resulting in greater durability and a more premium feel.

2. Is microfiber leather easy to clean and maintain?

Yes, it is remarkably low-maintenance. Most spills and stains can be wiped away with a soft, damp cloth. For deeper cleaning, a mild soap solution is usually sufficient. It is advisable to avoid harsh chemicals or abrasive cleaners to preserve the surface finish. Unlike genuine leather, it does not require conditioning or specialized leather care products.

3. Can microfiber leather be considered an eco-friendly choice?

Its environmental profile is nuanced but has distinct advantages. It is a vegan material, reducing the environmental impact associated with livestock. Its production can be more efficient and less polluting than chrome-tanning. However, as a petroleum-derived product, its lifecycle is a consideration. The industry is advancing with more sustainable practices, including the use of recycled polyester fibers and water-based polyurethane coatings.

4. How does the breathability of microfiber leather compare to genuine leather?

High-quality microfiber leather offers excellent breathability, often comparable to that of genuine leather. Its non-woven, fibrous structure creates microscopic air channels that allow for effective moisture vapor transmission, making it comfortable for prolonged contact with skin.

5. What should I look for to identify high-quality microfiber leather?

Premium microfiber leather will have a uniform, supple texture without a plastic-like feel or strong chemical odor. The grain pattern should look detailed and natural. When gently pressed or folded, it should not leave a permanent white crease and should spring back smoothly. A thick, dense feel is also a good indicator of a high-quality base layer designed for longevity.

In conclusion, microfiber leather stands as a testament to material innovation, successfully bridging the gap between luxury, performance, and responsibility. It delivers the aesthetic and tactile qualities desired by consumers while providing the durability and consistency demanded by manufacturers. As technology progresses, this next-generation material is poised to play an increasingly central role in shaping the future of sustainable and high-performance design across global industries.

Recommended Products

Recently Viewed

Exploring Synthetic Leather: A Versatile and Sustainable Alternative for Modern Design

Exploring Synthetic Leather: A Versatile and Sustainable Alternative for Modern Design The Future of Faux: Exploring the Versatility and Benefits of Synthetic Leather

The Future of Faux: Exploring the Versatility and Benefits of Synthetic Leather Wholesale Artificial Leather Material Pvc Synthetic Leather Fabric

Wholesale Artificial Leather Material Pvc Synthetic Leather Fabric Interpret The Production Process and Advantageous Applications of Microfiber Leather

Interpret The Production Process and Advantageous Applications of Microfiber Leather The King of Durability and Cost-effectiveness: PU Synthetic Leather

The King of Durability and Cost-effectiveness: PU Synthetic Leather

Contact Us

Fujian Huaxia Synthetic Leather Co., Ltd.