Welcome!

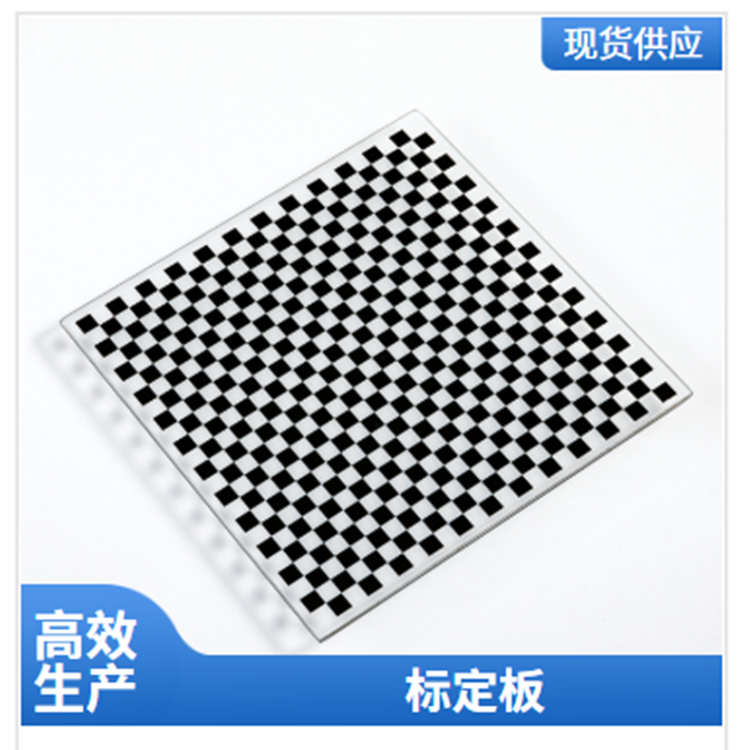

Optical glass checkerboard calibration board

Product Description

Optical calibration plate.

Application field.

Hongcheng Optical Glass Series Calibration Board and Ceramic Series Calibration Board are commonly used calibration tools for university experiments, research unit project research and development, machine vision integrator product calibration and other customer groups, which can easily obtain camera calibration data.

The function of the calibration board:

In order to correct lens distortion, determine the conversion relationship between physical size and pixels, and determine the relationship between the three-dimensional geometric position of a point on the surface of a space object and its corresponding point in the image, it is necessary to establish a geometric model of camera imaging. It is a special high-precision calibration tool for research unit and vision field, such as 3D image measurement, 3D reverse engineering, stereo matching, 3D reconstruction and so on.

Hongcheng optics can customize all kinds of calibration board and correction film.

Calibrate the plate material:

Material 1: soda glass: the color of the calibration board is silver in Russia, blue in Germany and Austria, and yellow in the United States and Japan. This color is determined by the coating process, and the quality of the calibration board cannot be judged by the color alone. The high-end color of the domestic standard board is yellow, and the cost of other colors is relatively low. Standard production process: glass substrate should be polished, cleaned, coated and so on. The film is firm and there are few defects in the post-production process. If one of the processes is reduced or the machine used is not very good, the cost of the product will be much cheaper, and the quality must not be very good. Example: if it is made according to the normal process and the size is 63mm*63mm, the price of mass production is at least 100 yuan.

Material 2: the standard plate of ceramic substrate has the characteristics of low coefficient of thermal expansion, high strength, high hardness, good wear resistance, low thermal conductivity, good acid and alkali resistance, and its good surface diffuse reflection treatment, which solves the problem of glass material calibration board reflection in the process of application, which can better identify the calibration board pattern detail information and achieve higher calibration accuracy and measurement accuracy.

Material 3: quartz material, the light transmittance of the material is good, the biggest advantage: the coefficient of expansion is small. In the process of calibrating the instrument, it is less affected by the ambient temperature. The corresponding cost is also very high. Quartz materials are divided into JGS1 and JGS2. JGS1 is expensive. JGS2 is relatively cheap with bubbles in it.

Material 4: matte metal aluminum calibration board: the greatest advantage of this calibration board is fall resistance, durability, opacity and non-reflection. Its good surface diffuse reflection treatment solves the problem of glass material calibration plate reflection in the case of front light source in the application process, and better identifies the calibration pattern details in order to achieve higher calibration accuracy and measurement accuracy.

Material 5: photo paper material: advantages: light and thin, non-reflective, low cost, easy to make. The disadvantage is that it is not waterproof and oil-proof.

Material 6: film material: film is film, which is generally composed of five parts: protective film, photosensitive emulsion, adhesive layer, film base, anti-halo layer. When the light shines on the silver halide, the silver halide is transformed into black silver, which is fixed to the film base after the development process, and becomes a common black-and-white negative film. The color negative is smeared with three layers of silver halide to show the three primary colors.

About the selection of calibration plate:

one。. Select the size of the plate:

Select a suitable calibration board according to the size of the field of view. In the halcon document, it is recommended that the pattern size of the calibration board should be at least greater than 1x4 field of view, less than the whole field of view, and take 15-20 calibration images; it is recommended that the pattern of the calibration board be larger than the field of view, which is smaller than the whole field of view, and the number of calibration images depends on the requirements; for the halcon12 version of the calibration board, it is recommended that the pattern of the calibration board is larger than the field of view area, and there are about 5 calibration images with different attitudes. The halcon12 version of the calibration board currently supports only halcon12, but the halcon12 version of the software can use the previous version of the calibration board.

Two, two. How to select and calibrate the plate material:

For the front light source, please select the ceramic / metal material calibration plate to avoid reflection. The backlight can choose the optical glass material.

three。. The drawing of the calibration board is as follows:

1. Materials need to be attached.

two。. Precision.

3. Dimensional tolerances, thickness.

4. Production effect drawings: the difference between positive and negative plates. (if you consider the price factor, you need to emphasize how many multiples are allowed to see the defects below).

5. Need to provide detailed CAD drawings (it is best not to draw scale drawings). The above is the complete information of the calibration board.

We can calibrate the accuracy of the plate to 1um. The color can be dark yellow, blue, silver, dark blue. The positioning hole can be drilled on the board, and the size can be used as a large calibration board around 800*960mm to meet the needs of customers with large field of view calibration.

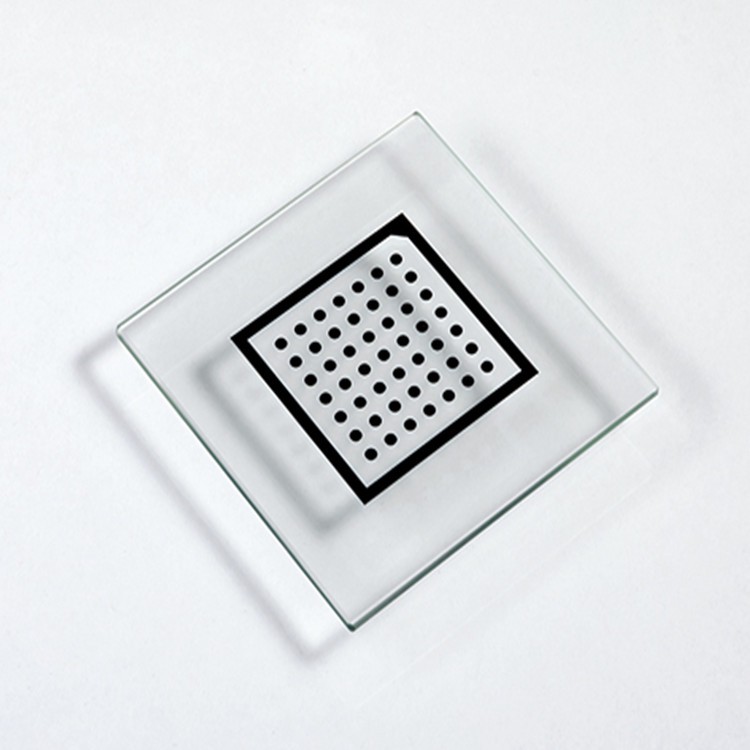

| halcon圆点标定板常见规格 | |||||

| 型号 | 外形尺寸(mm) | 有效面积(mm) | 圆直径(mm) | 圆心距(mm) | 阵列 |

| HC-H5.6-0.35 | 比图形面积稍大 | 5.6*5.6 | 0.35 | 0.7 | 7*7 |

| HC-H8-0.5 | 8.8*8.8 | 8*8 | 0.5 | 1 | 7*7 |

| HC-H10-0.625 | 比图形面积稍大 | 10*10 | 0.625 | 1.25 | 7*7 |

| HC-H16-1 | 16*16 | 16*16 | 1 | 2 | 7*7 |

| HC-H20-1.25 | 比图形面积稍大 | 20*20 | 1.25 | 2.5 | 7*7 |

| HC-H30-1.6 | 50*50或者30*30 | 30*30 | 1.6 | 3.2 | 7*7 |

| HC-H30-1.875 | 50*50或者30*30 | 30*30 | 1.875 | 3.75 | 7*7 |

| HC-H36-2 | 63*63 | 36*36 | 2 | 4 | 7*7 |

| HC-H63-3 | 63*63 | 63*63 | 3 | 6 | 7*7 |

| HC-H100-4 | 100*100 | 64*64 | 4 | 8 | 7*7 |

| HC-H100-6.25 | 100*100 | 100*100 | 6.25 | 12.5 | 7*7 |

| HC-H150-10 | 150*150 | 150*150 | 10 | 20 | 7*7 |

| HC-H200-12.5 | 200*200 | 200*200 | 12.5 | 25 | 7*7 |

| HC-H300-20 | 300*300 | 300*300 | 20 | 40 | 7*7 |

常规棋盘格:

| 棋盘格标定板(玻璃/陶瓷) | ||||

| 型号 | 外形尺寸mm | 有效面积mm | 格子大小 | 阵列 |

| HCM03-B63-1 | 63*63 | 48*48或56*56 | 1*1 | 48*48或者56*56 |

| HCM03-B63-2 | 63*63 | 48*48或52*52 | 2*2 | 28*28 |

| HCM03-B63-3 | 63*63 | 54*54 | 3*3 | 18*18 |

| HCM03-B63-4 | 63*63 | 48*48 | 4*4 | 12*12 |

| HCM03-B63-5 | 63*63 | 45*45(有框/无框) | 5*5 | 9*9 |

| HCM03-B100-1 | 100*100 | 90*90 | 1*1 | 90*90 |

| HCM03-B100-2 | 100*100 | 92*92 | 2*2 | 46*46 |

| HCM03-B100-3 | 100*100 | 90*90 | 3*3 | 30*30 |

| HCM03-B100-4 | 100*100 | 96*96 | 4*4 | 24*24 |

| HCM03-B100-5 | 100*100 | 90*90 | 5*5 | 18*18 |

| HCM03-B120-3 | 120*120 | 90*90 | 3*3 | 90*90 |

| HCM03-HC120-4 | 120*120 | 100*100 | 4*4 | 25*25 |

| HCM03-B125-4 | 125*125 | 120*120 | 5*5 | 24*24 |

| HCM03-B200-2 | 200*200 | 180*180 | 2*2 | 90*90 |

| HCM03-B200-3 | 200*200 | 189*189 | 3*3 | 63*63 |

| HCM03-B200-4 | 200*200 | 180*180 | 4*4 | 45*45 |

| HCM03-B200-5 | 200*200 | 180*180/185*185/190/190 | 5*5 | 36*36/37*37/38*38 |

| HCM03-B200-10 | 200*200 | 180*180 | 10*10 | 18*18 |

| HCM03-B220-2 | 220*220*3 | 202*202 | 2*2 | 101*101 |

| HCM03-B260-20 | 260*200*3 | 240*180 | 20*20 | 12*9 |

| HCM03-B300-3 | 300*300 | 294*294 | 3*3 | 98*98 |

| HCM03-B300-20 | 300*300 | 280*280 | 20*20 | 14*14 |

1. Product name: checkerboard glass calibration board 63mm*63mm.

2. Product model: HCM01-63F.

3. External dimensions: 63 "63" 5.

4. Graphic size (mm): 50-50.

5. Square size (mm): 2x2.

6. Accuracy (μ m): 2.

7. Material: glass.

8. Whether there is a border: no.

9. Pattern type: squares

Recommended Products

Recently Viewed

Contact Us

Dongguan Hongcheng Optical products Co., Ltd.