Welcome!

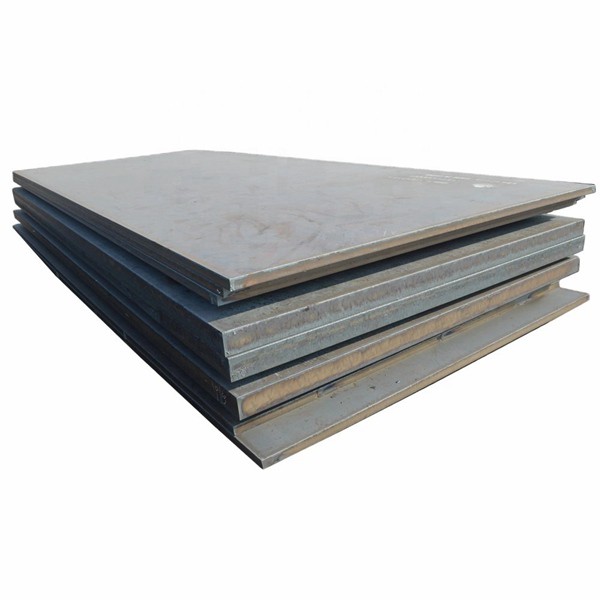

Wholesale Hot Rolled Cold Rolled Steel Sheet Mild Carbon Steel Sheet/Plate

Product Description

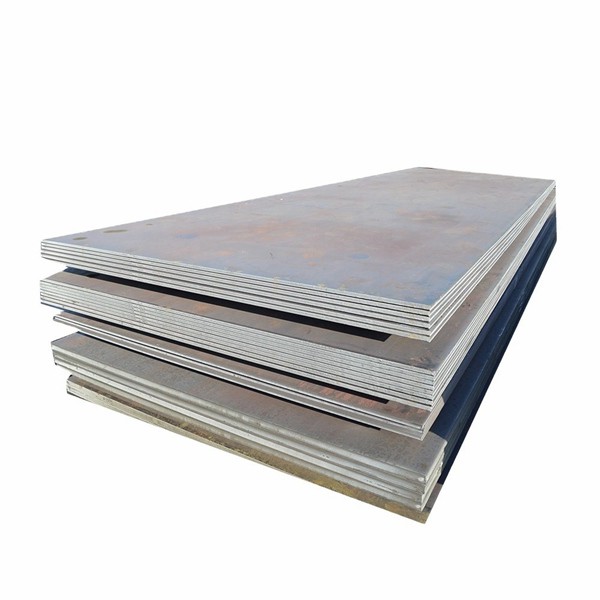

With the advancement of technology and industrial development, the application fields and demand for low-carbon steel plates will continue to expand. In the future, low-carbon steel plates will pay more attention to environmental protection, energy conservation, and sustainable development. For example, adopting more environmentally friendly steelmaking processes and rolling technologies to reduce energy consumption and pollutant emissions; Meanwhile, through technological innovation and process optimization, the performance and quality of low-carbon steel plates can be improved to meet stricter usage requirements.

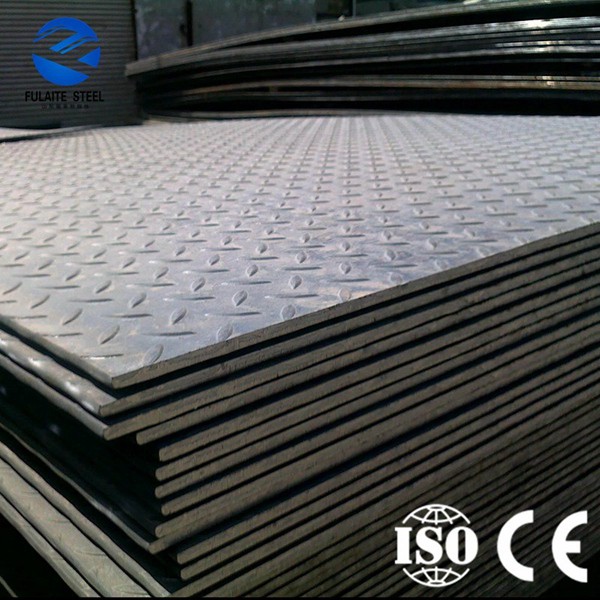

Low carbon steel plates are widely used in many fields such as automotive manufacturing, construction, home appliances, shipbuilding, and mechanical manufacturing due to their excellent performance and wide applicability. Whether as a structural material or a decorative material, low-carbon steel plates can meet various needs. Low carbon steel plates play an important role in modern industry due to their excellent processing performance, excellent mechanical properties, excellent corrosion resistance, environmental protection and energy conservation, and wide application fields.

Low carbon steel plates can undergo various anti-corrosion treatments on their surface, such as galvanizing, painting, etc., to improve their corrosion resistance. This enables low-carbon steel plates to maintain good performance and service life in harsh environments such as humidity and corrosion. In the production process of low-carbon steel plates, due to their low carbon content, energy consumption and carbon dioxide emissions can be reduced, which meets the requirements of environmental protection and energy conservation. During use, low-carbon steel plates are also easy to recycle and reuse, reducing resource waste and environmental pollution.

Low carbon steel plates have good plasticity and toughness, making them easy to perform processing operations such as stamping, bending, and welding. These processing properties have made low-carbon steel plates widely used in the manufacturing industry. Due to its low carbon content, low-carbon steel plates are less prone to cracking and porosity during welding, ensuring the quality and strength of welded joints. Low carbon steel plates are used to manufacture the shells and internal structural components of household appliances such as refrigerators, washing machines, and air conditioners. Its excellent processing performance and surface quality make household appliances more beautiful and durable.

Low carbon steel plate is a type of steel plate with a lower carbon content. Specifically, the carbon content in low-carbon steel plates is generally less than 0.25%, which gives them a series of unique advantages compared to other high carbon steel plates. Due to its low carbon content, low-carbon steel plates exhibit good plasticity and toughness during processing, making them easy to perform processing operations such as stamping, bending, and welding. At the same time, low-carbon steel plates also have excellent welding performance, and welding joints are not prone to cracking and porosity, ensuring welding quality. In addition, low-carbon steel plates also have high strength and hardness, which can meet the needs of various industrial applications.

Recommended Products

Recently Viewed

Chinese manufacturers Wear-Resistant Carbon Steel Plate, , Ship Steel Plate, Mild Carbon Steel Plate

Chinese manufacturers Wear-Resistant Carbon Steel Plate, , Ship Steel Plate, Mild Carbon Steel Plate China Mill Factory 1mm 3mm 10mm Thick Steel Sheet Price Black Steel Sheet

China Mill Factory 1mm 3mm 10mm Thick Steel Sheet Price Black Steel Sheet China Mill Factory Mild Iron Plates HRC Thick Steel Sheet Carbon Steel Plate

China Mill Factory Mild Iron Plates HRC Thick Steel Sheet Carbon Steel Plate Chinese manufacturers Hot Rolled Low Carbon Steel Sheet Coil Plate

Chinese manufacturers Hot Rolled Low Carbon Steel Sheet Coil Plate Manufacturer's price 1mm 3mm 10mm Thick Steel Sheet Price Black Steel Sheet

Manufacturer's price 1mm 3mm 10mm Thick Steel Sheet Price Black Steel Sheet

Contact Us

Guangdong DEF Seals Solutions Co., Ltd.