Welcome!

Customized High Carbon Steel Square Wire Netting Crimped Weave Wire Mesh

Product Description

High carbon silk cloth, as a high-performance new material, is gradually showing its unique charm and wide application prospects in multiple fields. This material is mainly made by spinning high-performance carbon fiber filaments through special processes. It not only inherits many advantages of carbon fiber, but also endows it with more characteristics through special textile processes.

The production process and technology of high carbon silk cloth is a complex and delicate process that requires strict control of each link to ensure the performance and quality of the final product. With the continuous advancement of technology and the expansion of application fields, high carbon silk cloth will undoubtedly play its unique role and value in more fields. High carbon silk cloth, as a high-performance new material, is gaining more and more attention and favor due to its unique charm and wide application prospects. We have reason to believe that in the future, high carbon fiber cloth will demonstrate its enormous potential and value in more fields.

Carbonized carbon fiber filaments are woven into a fabric shape, forming a high carbon fiber cloth. During the weaving process, it is necessary to control the arrangement and density of fibers to ensure the performance of the final product. The woven high carbon silk fabric also needs post-processing, such as ultrasonic cleaning, heat treatment, stretching, and lubrication, to further enhance its mechanical properties and surface quality. Post processing techniques such as ultrasonic cleaning and heat treatment can further remove impurities and defects on the surface of fibers, improving their mechanical properties and surface quality.

The spun carbon fiber filaments need to undergo carbonization treatment to form high-strength carbon fibers. The carbonization process is usually carried out at high temperatures, causing fibers to decompose into pure carbon in an oxygen deficient environment. The carbonization temperature and time have a significant impact on the quality and properties of carbon fibers. Carbonization is a crucial step in the production of high carbon silk fabric. The control of carbonization temperature, time, and atmosphere has a significant impact on the mechanical properties, structural stability, and thermal stability of carbon fibers. During the carbonization process, inert gases (such as nitrogen, argon, etc.) need to be used as a protective atmosphere to prevent fibers from oxidizing at high temperatures.

Recommended Products

Recently Viewed

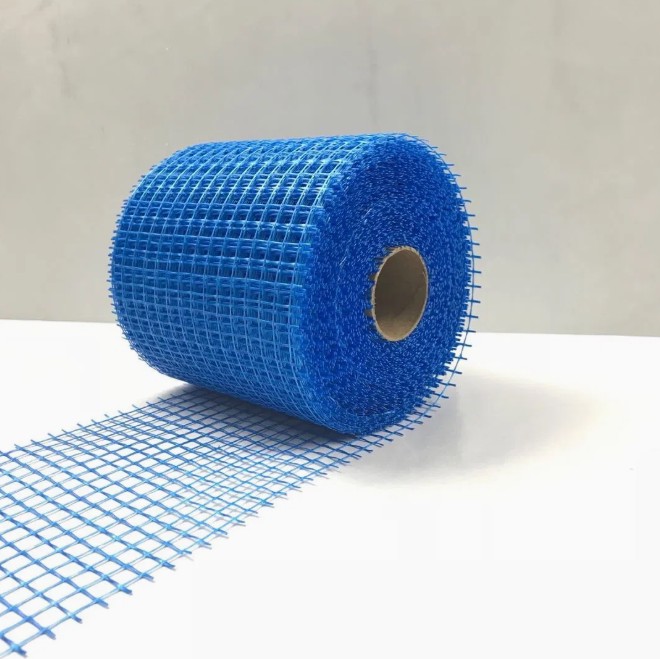

Unveiling the Versatility of Fiberglass Mesh: A Comprehensive Guide

Unveiling the Versatility of Fiberglass Mesh: A Comprehensive Guide Unveiling the Power of Fiberglass Mesh: Strength Meets Versatility

Unveiling the Power of Fiberglass Mesh: Strength Meets Versatility Introduction to the basic parameters and applications of glass fiber mesh

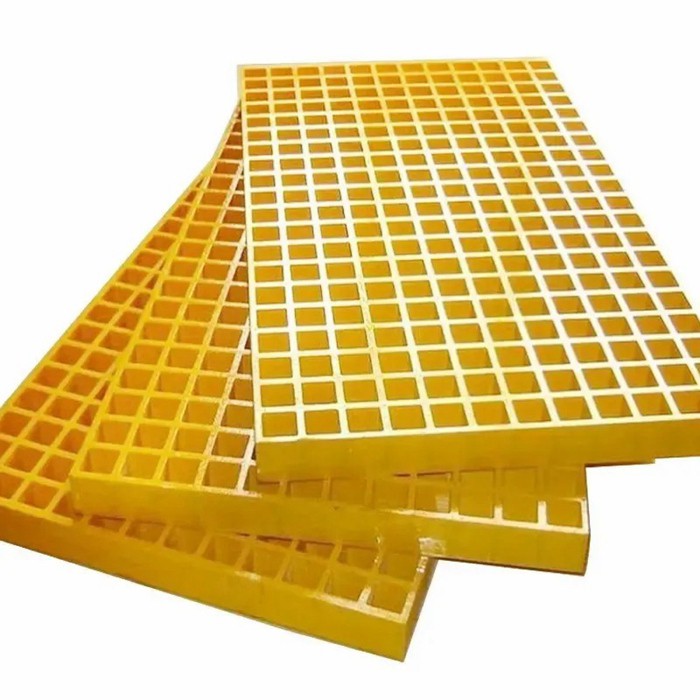

Introduction to the basic parameters and applications of glass fiber mesh China Produces Glass Fiber Grids That Are Corrosion-resistant, Freproof and Moisture-proof

China Produces Glass Fiber Grids That Are Corrosion-resistant, Freproof and Moisture-proof Unlocking the Versatility of Fiberglass Mesh: A Comprehensive Guide

Unlocking the Versatility of Fiberglass Mesh: A Comprehensive Guide

Contact Us

Yosaite (Qingdao) Construction Materials Co., Ltd.