Welcome!

High Quality 60 Mesh Herringbone Mild Steel Black Wire Cloth

Product Description

The choice of spinning technology directly affects the performance of carbon fibers. Wet spinning, dry spinning, and dry spray wet spinning each have their own advantages and disadvantages, and the appropriate spinning method should be selected according to product specifications and performance requirements. Wet spinning is a traditional spinning method suitable for the production of large fiber bundles of carbon fibers. Dry jet wet spinning combines dry spinning and wet spinning to produce smaller carbon fiber bundles with better performance. During the spinning process, it is necessary to strictly control parameters such as spinning speed, temperature, and pressure to ensure the uniformity and quality of the fibers.

Recommended Products

Recently Viewed

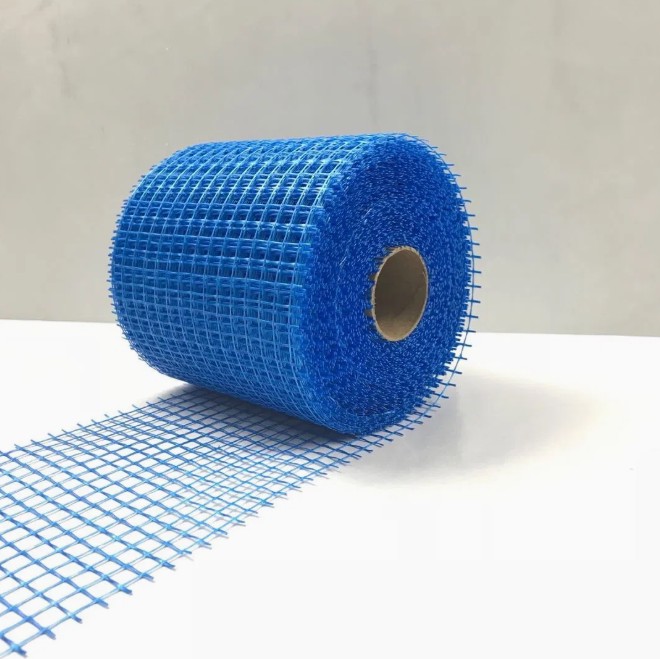

Unveiling the Versatility of Fiberglass Mesh: A Comprehensive Guide

Unveiling the Versatility of Fiberglass Mesh: A Comprehensive Guide Unveiling the Power of Fiberglass Mesh: Strength Meets Versatility

Unveiling the Power of Fiberglass Mesh: Strength Meets Versatility Introduction to the basic parameters and applications of glass fiber mesh

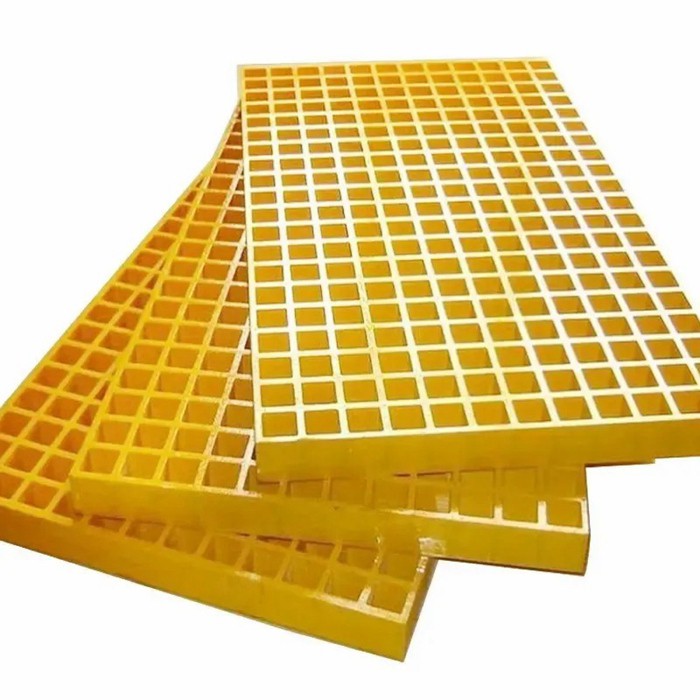

Introduction to the basic parameters and applications of glass fiber mesh China Produces Glass Fiber Grids That Are Corrosion-resistant, Freproof and Moisture-proof

China Produces Glass Fiber Grids That Are Corrosion-resistant, Freproof and Moisture-proof Unlocking the Versatility of Fiberglass Mesh: A Comprehensive Guide

Unlocking the Versatility of Fiberglass Mesh: A Comprehensive Guide

Contact Us

Yosaite (Qingdao) Construction Materials Co., Ltd.