Welcome!

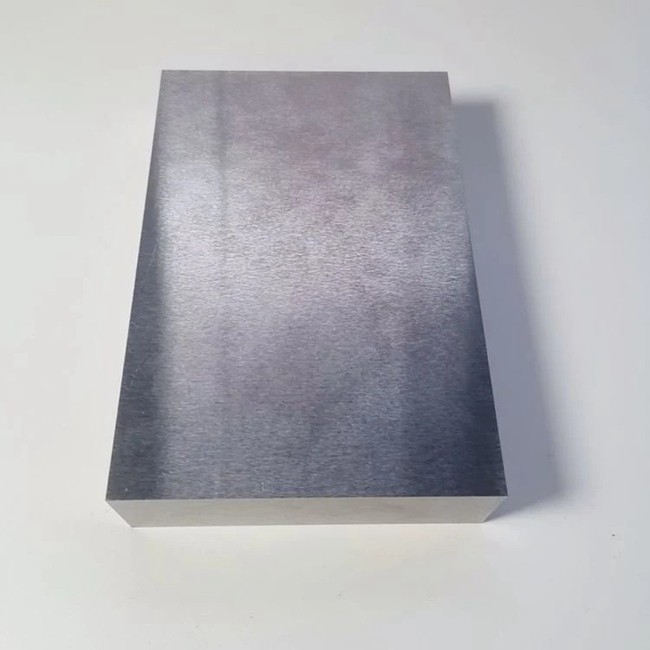

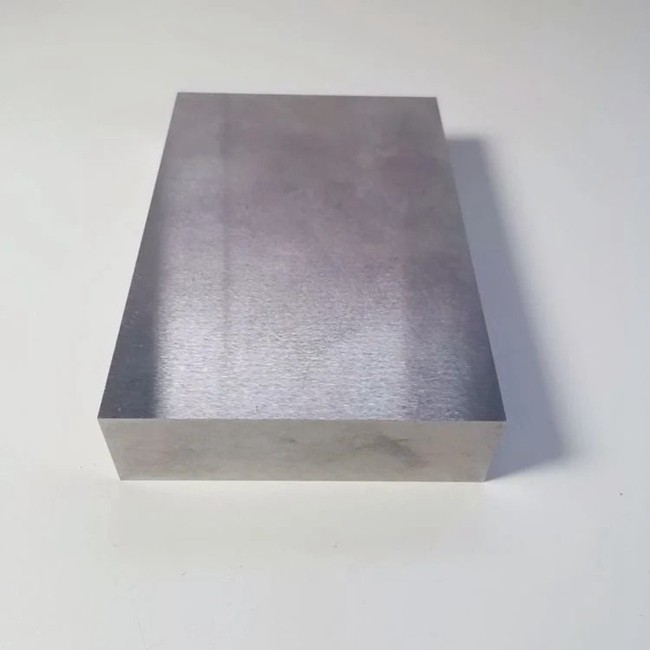

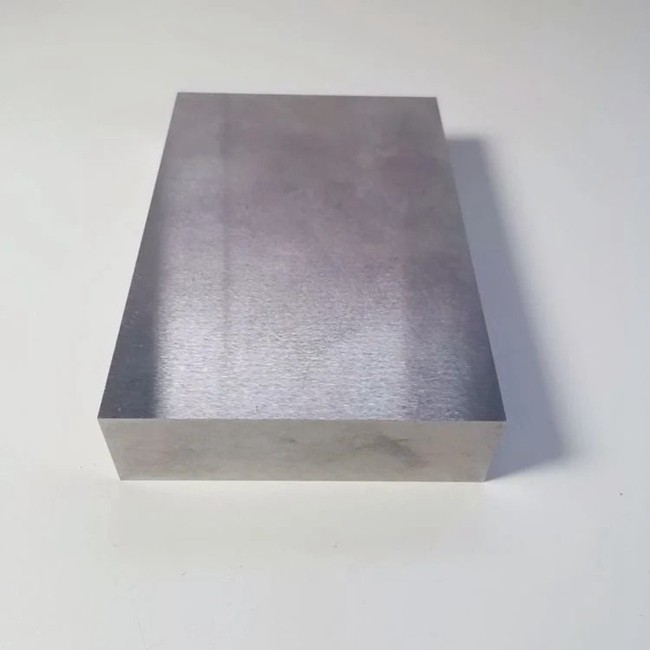

Professional Finished Tungsten Carbide Strip with High Hardness Grade

Product Description

Tungsten carbide also plays an important role in mining and drilling. Drill bits in oil and gas drilling often contain tungsten carbide to cope with hard rocks and formations. The high hardness and abrasion resistance of tungsten carbide allows the drill bit to penetrate formations more quickly, increasing drilling efficiency. Meanwhile, in mining operations, tungsten carbide is also used to manufacture wear-resistant parts such as crusher hammer heads and grinding media to cope with harsh working conditions.

As a metal carbide with excellent performance, tungsten carbide plays an important role in several industrial fields. It is not only a hard and sharp edge for cutting tools and molds, but also a powerful assistant in mining, drilling, wear-resistant parts and aerospace. With the continuous progress of technology and the expansion of application areas, the future of tungsten carbide will be brighter.

Tungsten carbide has a wide range of applications in many occasions due to its excellent properties such as high hardness, high wear resistance and high corrosion resistance. Tungsten carbide is the main raw material for manufacturing tungsten carbide tools (such as drills, milling cutters, turning tools, etc.). These tools play a key role in metal processing, wood processing, stone processing and other industries, and are able to cut a variety of materials efficiently and accurately. In mold manufacturing, tungsten carbide is also often used to make mold cores, punches, mold inserts, etc. to improve the wear resistance and service life of molds.

In mining operations, tungsten carbide is also used in the manufacture of crusher hammer heads, grinding media, etc. to cope with harsh working conditions. Due to its high hardness and wear resistance, tungsten carbide has a wide range of applications in mining and drilling. For example, drill bits in oil and gas drilling often contain tungsten carbide to improve their ability to penetrate rocks and strata. Tungsten carbide plays an important role in cutting tools and dies, mining and drilling, wear-resistant parts and components, coatings and films, aerospace, and other industrial applications.

Tungsten carbide is most widely used in the field of cutting tools and mold making. As the main component of tungsten carbide, tungsten carbide cutting tools, with its high hardness, high wear resistance and excellent cutting performance, have made their mark in metalworking, woodworking, stone processing and other industries. Whether it is drills, milling cutters or turning tools, tungsten carbide can significantly improve the processing efficiency and processing quality. In addition, in the manufacture of molds, tungsten carbide is often used in the manufacture of mold cores, punches and other key components to improve the service life and precision of molds.

Recommended Products

Recently Viewed

OEM Customized Finished Tungsten Carbide Strip with High Hardness Grade

OEM Customized Finished Tungsten Carbide Strip with High Hardness Grade Factory Wholesale Carbide Square Bar Tungsten Carbide Tool Parts

Factory Wholesale Carbide Square Bar Tungsten Carbide Tool Parts Professional Wear Block Cemented Tungsten Carbide Tool Parts

Professional Wear Block Cemented Tungsten Carbide Tool Parts Professional Finished Tungsten Carbide Strip Tool Parts

Professional Finished Tungsten Carbide Strip Tool Parts Factory Wholesale Carbide Square Bar Tungsten Carbide with High Hardness Grade

Factory Wholesale Carbide Square Bar Tungsten Carbide with High Hardness Grade

Contact Us

Hangzhou Hengli Metal Processing Co., Ltd.