Welcome!

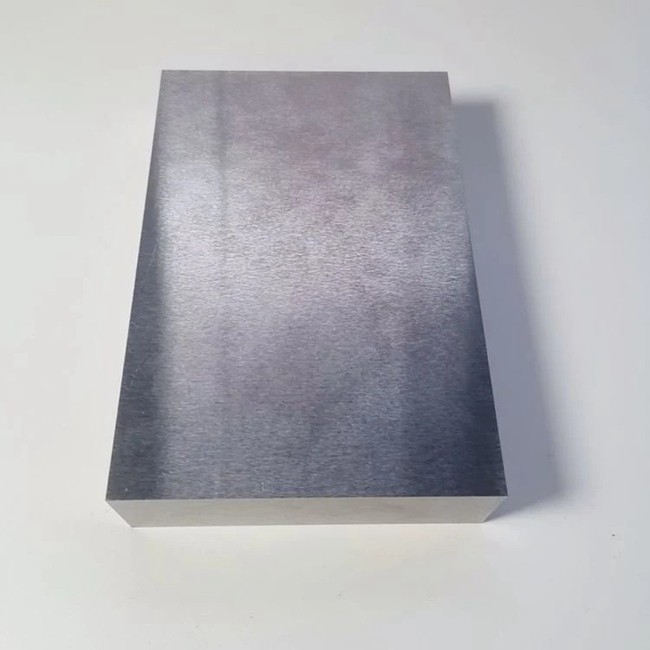

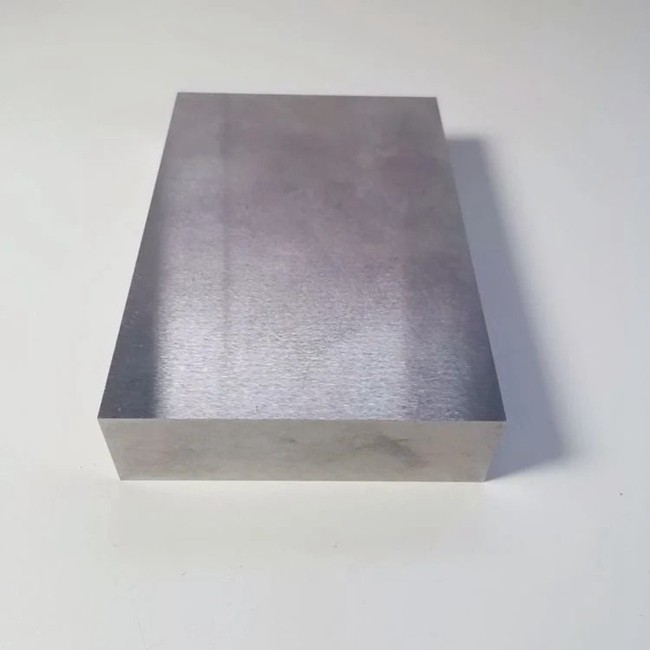

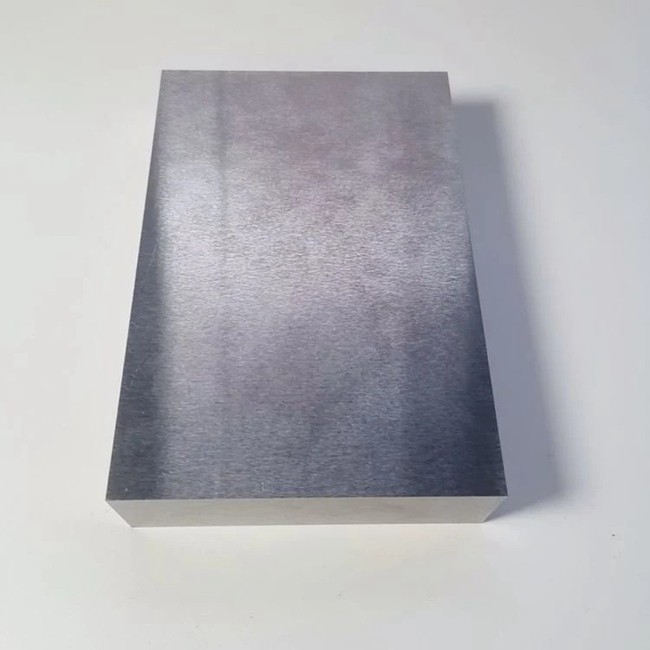

Factory Wholesale Carbide Square Bar Tungsten Carbide with High Hardness Grade

Product Description

Due to its excellent properties such as high hardness, high wear resistance and high corrosion resistance, tungsten carbide is the main raw material for the production of cemented carbide, which is widely used in cutting tools, molds, wear-resistant parts and other fields. Tungsten carbide coating has excellent wear resistance, impact resistance and corrosion resistance, and is used for surface treatment of bearings, valves, pumps and other parts.

In mining operations, tungsten carbide is also used in the manufacture of crusher hammer heads, grinding media, etc. to cope with harsh working conditions. Due to its high hardness and wear resistance, tungsten carbide has a wide range of applications in mining and drilling. For example, drill bits in oil and gas drilling often contain tungsten carbide to improve their ability to penetrate rocks and strata. Tungsten carbide plays an important role in cutting tools and dies, mining and drilling, wear-resistant parts and components, coatings and films, aerospace, and other industrial applications.

Tungsten carbide is used in the manufacture of a variety of wear-resistant parts and components such as bearings, sealing rings, and nozzles. These parts maintain long service life and stable performance when operating at high speeds, high temperatures, high pressures or in corrosive environments. Tungsten carbide coatings and films are widely used in mechanical parts, electronic components, medical devices and other fields due to their excellent wear resistance, corrosion resistance and high temperature stability. These coatings and films can be prepared by chemical vapor deposition, physical vapor deposition and other methods to improve the surface properties of the base material.

Tungsten carbide is usually prepared by carbothermal reduction, powder metallurgy or chemical vapor deposition. Among them, powder metallurgy is one of the most commonly used methods, which is made by mixing tungsten and carbon powders, pressing them into shape, and then sintering them at high temperatures. This method is not only a mature process, but also capable of producing tungsten carbide products with complex shapes and excellent performance.

Recommended Products

Recently Viewed

OEM Customized Finished Tungsten Carbide Strip with High Hardness Grade

OEM Customized Finished Tungsten Carbide Strip with High Hardness Grade Factory Wholesale Carbide Square Bar Tungsten Carbide Tool Parts

Factory Wholesale Carbide Square Bar Tungsten Carbide Tool Parts Professional Wear Block Cemented Tungsten Carbide Tool Parts

Professional Wear Block Cemented Tungsten Carbide Tool Parts Professional Finished Tungsten Carbide Strip Tool Parts

Professional Finished Tungsten Carbide Strip Tool Parts Factory Wholesale Carbide Square Bar Tungsten Carbide with High Hardness Grade

Factory Wholesale Carbide Square Bar Tungsten Carbide with High Hardness Grade

Contact Us

Hangzhou Hengli Metal Processing Co., Ltd.