Welcome!

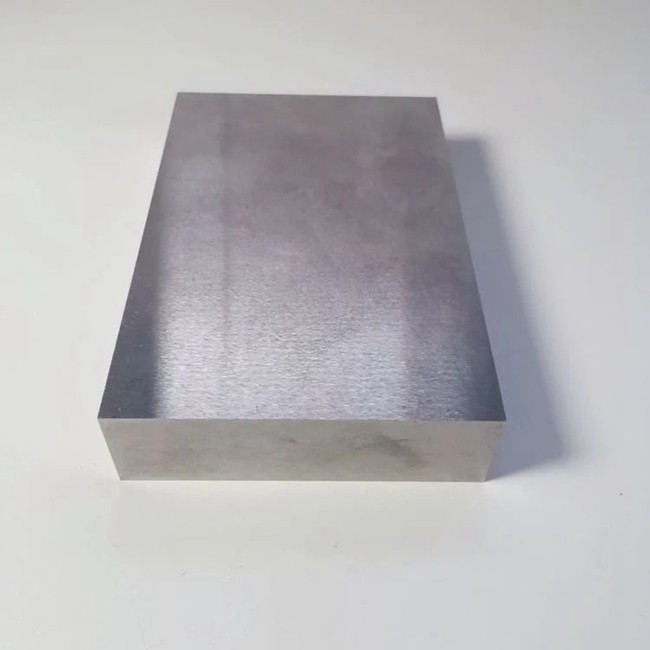

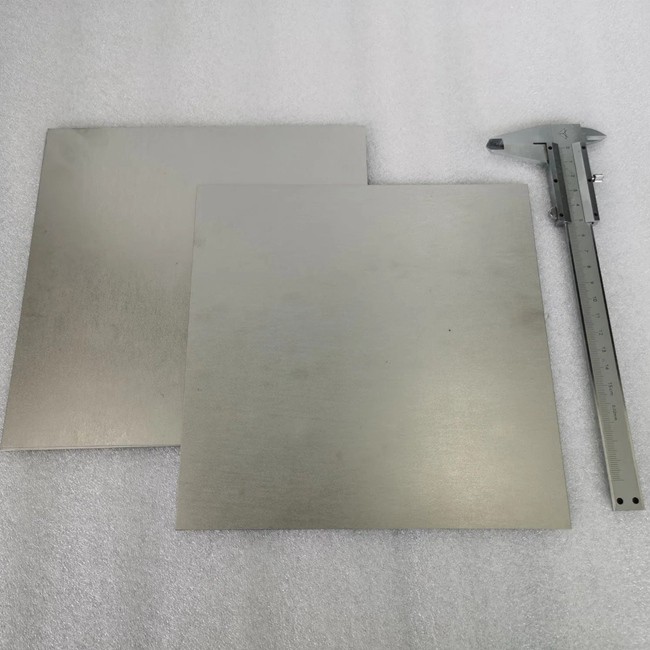

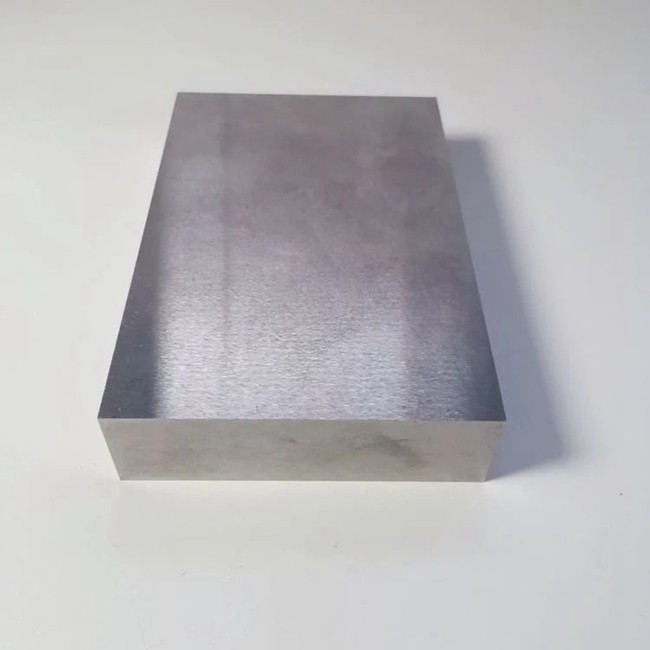

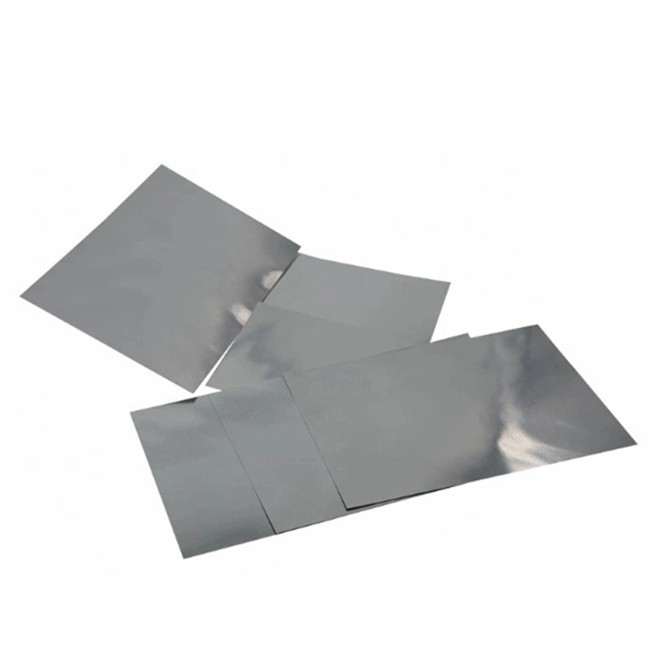

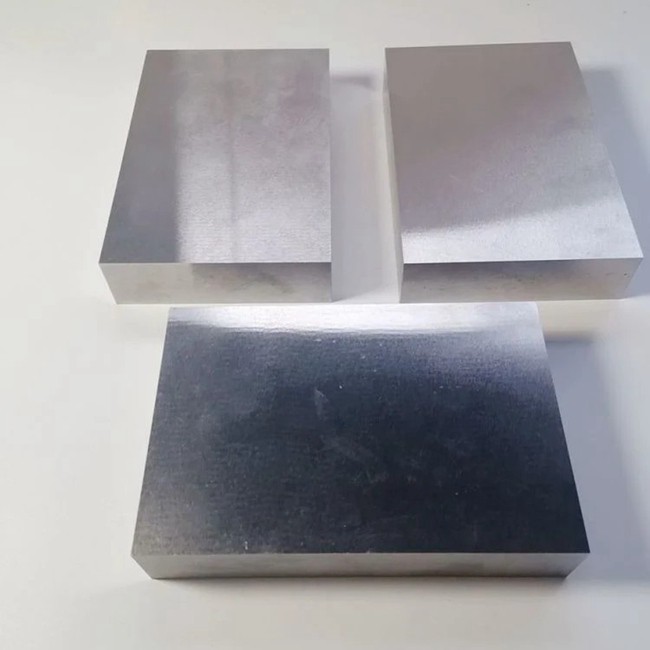

Factory Custom Square Sheet Tungsten Carbide Flat Blanks Plate for Mold Making

Product Description

Tungsten alloy plate is a kind of composite plate synthesized from tungsten and other metals (e.g. nickel, iron, copper, etc.) through a special process. With its unique physical and chemical properties, this alloy has shown great application value in many fields. Tungsten alloy plates are known for their extremely high density, which gives them excellent weight-carrying capacity and compression resistance. This high density property makes tungsten alloy sheet perform well in applications that require high weight or high density materials, such as armor-piercing bullets in the military and counterweights for sports equipment.

Tungsten alloy plate is a dense, radiation-absorbing material that can effectively resist and absorb the effects of high-energy radiation from X-rays, γ-rays and neutron radiation. This characteristic makes it widely used in the nuclear industry, medical equipment and aerospace and aviation, etc., for the manufacture of radiation protection and ray diagnostic equipment.

Due to its high density and high strength characteristics, tungsten alloy plate is widely used in the manufacture of a variety of defense and military equipment, such as heavily armored kinetic energy armor-piercing bullets, bullets, rifles, missiles and bombs. At the same time, tungsten alloy plate is also used in the manufacture of some special-purpose counterweights, such as yacht counterweights and airplane ballasts.

Despite its high hardness, tungsten alloy sheet also has good ductility and plasticity. the elongation of W-Ni-Fe high-density alloy in the sintered state can be up to 10% 15%, and after vacuum or atmosphere dehydrogenation treatment, the elongation can be increased to 20% 30%. This characteristic makes tungsten alloy plate easy to process into various shapes and sizes, which is widely used in the fields of mold making, machining and high-precision instrument manufacturing.

The production of tungsten alloy plate is a complex and delicate process, which mainly includes several steps such as powder making, mixing, pressing and sintering. First of all, according to the specific use, select and proportion appropriate tungsten carbide powder and cobalt (Co) and other additives, and prepare a homogeneous mixture through the steps of wet grinding, mixing, crushing, drying and sieving. Subsequently, the molding agent is added for drying and sieving again to make a mixture that meets the requirements. After that, the mixture is pressed into the required shape by pressing process, and then the material is densified by sintering process to form tungsten alloy plate blanks. Finally, the quality of the product is ensured by flaw inspection, and finally packaged into the warehouse.

Recommended Products

Recently Viewed

Factory Made Tungsten Carbide Wear Parts Tungsten Carbide Plate for Making Industry Cutting Tools

Factory Made Tungsten Carbide Wear Parts Tungsten Carbide Plate for Making Industry Cutting Tools Factory Custom Yg15 Tungsten Steel Wear-Resistant Tungsten Carbide Square Plates in Various Sizes for Making Industry Cutting Tools

Factory Custom Yg15 Tungsten Steel Wear-Resistant Tungsten Carbide Square Plates in Various Sizes for Making Industry Cutting Tools Factory Made Carbide Sheet Tungsten Steel Plate for Mold Making

Factory Made Carbide Sheet Tungsten Steel Plate for Mold Making 100% Virgin Material Yg15 Tungsten Steel Wear-Resistant Tungsten Carbide Square Plates in Various Sizes for Making Industry Cutting Tools

100% Virgin Material Yg15 Tungsten Steel Wear-Resistant Tungsten Carbide Square Plates in Various Sizes for Making Industry Cutting Tools Factory Custom Yg15 Tungsten Steel Wear-Resistant Tungsten Carbide Square Plates in Various Sizes for Making Industry Cutting Tools

Factory Custom Yg15 Tungsten Steel Wear-Resistant Tungsten Carbide Square Plates in Various Sizes for Making Industry Cutting Tools

Contact Us

Jiangsu Xinmechan Technology Co., Ltd.