Welcome!

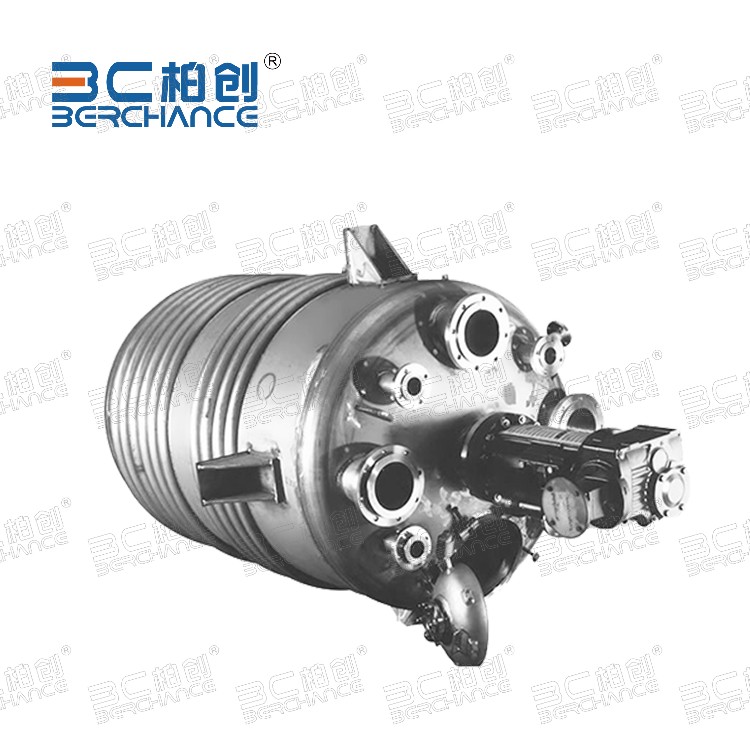

China Factory Double Jacket Electric/Steam Heating Pressure Liquid Blending Reaction Kettle

Product Description

Distillation kettle, as one of the core equipment in chemical separation technology, plays an important role in the chemical industry. With the continuous advancement and innovation of technology, the performance and functionality of distillation vessels will be further improved and perfected. In the future, distillation vessels will continue to play an important role in pharmaceutical, chemical, food and other fields, providing more efficient, environmentally friendly and safe solutions for chemical production.

Distillation vessels are widely used in various industries such as pharmaceuticals, chemicals, food, and light industry. In the pharmaceutical industry, distillation kettles are commonly used to extract active ingredients from drugs, such as extracting essential oils from plants or separating target products from fermentation broth. In the chemical industry, distillation kettles are used for the purification and separation of various chemicals, such as fraction cutting in petroleum processing and product purification in organic synthesis. In addition, in the food industry, distillation kettles are also used in the production process of extracting substances such as spices and alcohol.

A distillation kettle usually consists of the following main parts: kettle body, heater, condenser, receiver, and necessary pipelines and valves. The kettle body is generally made of corrosion-resistant materials, such as stainless steel or fiberglass, to withstand the pressure and temperature generated during the heating process. The heater is responsible for providing heat to bring the mixture to a boiling state. The condenser is used to cool the generated steam into liquid form for easy collection. The receiver is used to receive and store the separated components. In addition, the distillation kettle is equipped with temperature, pressure and other monitoring instruments to ensure the safety and stability of the operation process.

A reaction kettle is a comprehensive reaction vessel widely used in industries such as chemistry, medicine, and food. It achieves the required heating, evaporation, cooling, and material mixing functions through specific design structures and parameter configurations. A reactor is a container that undergoes physical or chemical reactions. The structure and parameter configuration of the container are designed according to different process conditions to achieve specific reaction processes.

In the vast field of chemical industry, distillation kettle plays an indispensable role as a key separation equipment. It utilizes the difference in boiling points of each component in the mixture to achieve effective separation of components through processes such as heating, vaporization, and condensation, providing important technical support for chemical production. The main function of a distillation kettle is to vaporize the distilled liquid and provide the necessary amount of rising steam in the tower to achieve effective separation of components. Widely used in pharmaceutical, chemical, food, light industry and other fields. In the pharmaceutical industry, distillation kettles are commonly used to extract active ingredients from drugs; In the chemical industry, it is used for the purification and separation of various chemicals.

Recommended Products

Recently Viewed

Stainless Steel Coil Reactor with Efficient Heat Transfer and Temperature Control

Stainless Steel Coil Reactor with Efficient Heat Transfer and Temperature Control Stainless Steel Storage Tank for Corrosive Liquids and Food-Grade Applications

Stainless Steel Storage Tank for Corrosive Liquids and Food-Grade Applications Stainless Steel Fermentation Tank with Automatic Temperature Control for Biotech and Food Industries

Stainless Steel Fermentation Tank with Automatic Temperature Control for Biotech and Food Industries High-Efficiency Stainless Steel Heat Exchanger for Chemical, Food, and Pharmaceutical Industries

High-Efficiency Stainless Steel Heat Exchanger for Chemical, Food, and Pharmaceutical Industries Stainless Steel Mixing Tank for Food, Chemical, and Pharmaceutical Applications

Stainless Steel Mixing Tank for Food, Chemical, and Pharmaceutical Applications

Contact Us

Zibo Gyro Industrial Fabrication and Sales Co., Ltd.