Welcome!

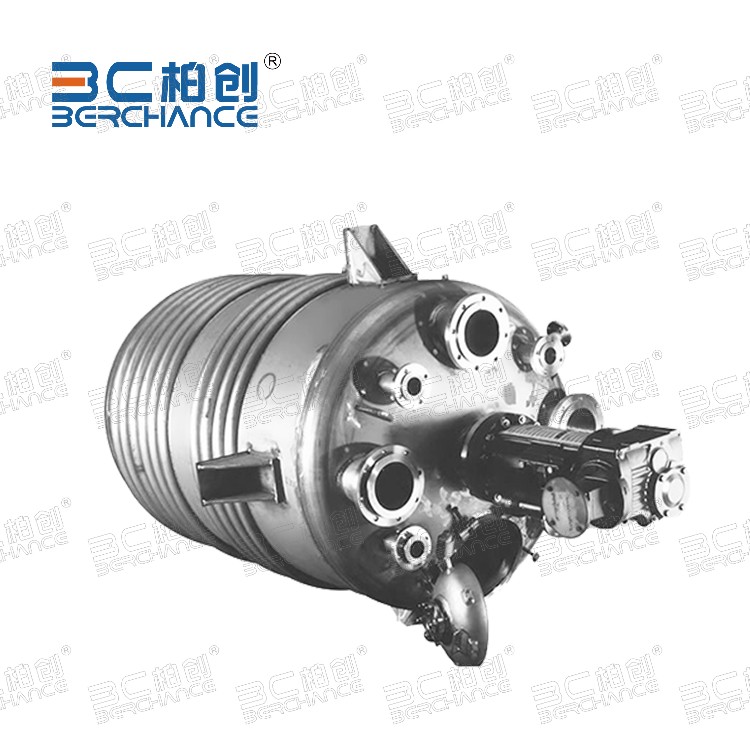

Stainless Steel Coil Reactor with Efficient Heat Transfer and Temperature Control

Product Description

Product Overview:

The coil-type stainless steel reactor is a highly efficient chemical equipment integrating heating, reaction, and mixing functions. It is widely used in pharmaceuticals, chemicals, food processing, and new materials industries for material reactions and heat transfer processes. The reactor features internal or external coil structures that ensure precise temperature control through heat transfer media like thermal oil, steam, or water.

Working Principle:

The coil reactor operates by circulating heating or cooling media through spiral coils placed either on the outer wall (external coil) or inside the vessel (internal coil). This design enables rapid and uniform heat exchange to maintain desired reaction conditions. The integrated agitator ensures complete mixing, promoting even temperature distribution and efficient reactions.

Key Features:

- High Heat Transfer Efficiency: Optimized coil layout ensures large heat exchange surface and rapid temperature change.

- Durable & Pressure-Resistant: Made from premium stainless steel, offering strong corrosion resistance and pressure tolerance.

- Excellent Process Adaptability: Suitable for high-temperature, high-pressure, and multiphase reaction processes.

- Precise Temperature Control: Supports integration with advanced temperature control systems to ensure reaction stability.

- Compact & Easy Maintenance: Space-saving design, easy to install, clean, and maintain.

- Customizable Design Options: Volume, coil type (internal/external), agitator structure, and sealing method can be tailored to customer needs.

Applications:

- Pharmaceutical synthesis

- Fine chemicals

- Food ingredients processing

- Polymerization reactions

- Thermal-sensitive materials handling

Recommended Products

Recently Viewed

Stainless Steel Coil Reactor with Efficient Heat Transfer and Temperature Control

Stainless Steel Coil Reactor with Efficient Heat Transfer and Temperature Control Stainless Steel Storage Tank for Corrosive Liquids and Food-Grade Applications

Stainless Steel Storage Tank for Corrosive Liquids and Food-Grade Applications Stainless Steel Fermentation Tank with Automatic Temperature Control for Biotech and Food Industries

Stainless Steel Fermentation Tank with Automatic Temperature Control for Biotech and Food Industries High-Efficiency Stainless Steel Heat Exchanger for Chemical, Food, and Pharmaceutical Industries

High-Efficiency Stainless Steel Heat Exchanger for Chemical, Food, and Pharmaceutical Industries Stainless Steel Mixing Tank for Food, Chemical, and Pharmaceutical Applications

Stainless Steel Mixing Tank for Food, Chemical, and Pharmaceutical Applications

Contact Us

Guangzhou Berchance Electromechanical Equipment Co., Ltd