Welcome!

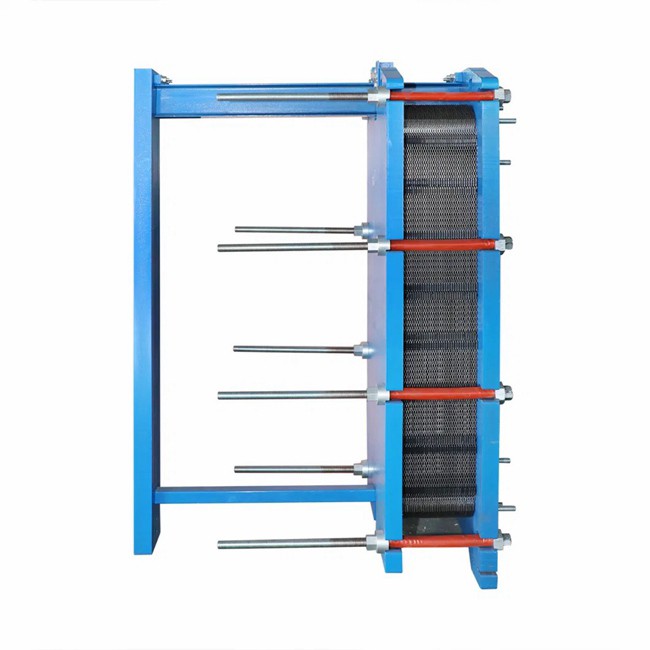

Good Quality Water Cool Chiller Refrigerated Air Dryer Stainless Plate Heat Exchanger

Product Description

The working principle of plate heat exchangers mainly includes three processes: heat transfer, mass transfer, and resistance. Cold and hot fluids flow through both sides of the plate heat exchanger, with the hot fluid releasing heat on the hot side plate and the cold fluid absorbing heat on the cold side plate, thereby achieving heat transfer. Heat is mainly transferred through convection and conduction. In addition, plate heat exchangers can also achieve mass transfer processes by adding appropriate fillers or membranes to transfer substances between the fluids on both sides.

Plate heat exchangers have a compact and lightweight structure, occupying a small area, only about one-third of that of tube heat exchangers. Plate heat exchangers can adjust the heat exchange area by changing the number of plates, and different baffles can be inserted to change the processing of cold and heat flows and the number of heat exchange sections to meet different process requirements. The heat transfer plate of the plate heat exchanger is processed by stamping, with high standardization, low consumables, and easy maintenance and cleaning.

Air dryer heat exchangers are widely used in various fields, such as industrial manufacturing, food processing, pharmaceutical and chemical industries, textile printing and dyeing, etc. In these fields, air dryer heat exchangers play a crucial role in ensuring smooth production processes and stable product quality.

There are various types of heat exchangers in air dryers, including plate fin heat exchangers and shell and tube heat exchangers. Among them, plate fin heat exchangers are widely used due to their compact structure and high heat transfer efficiency. It usually consists of a core, a head, a connecting pipe, and a support, and the core is a key component for completing heat exchange.

The heat exchanger in an air dryer is an important component that mainly condenses the moisture in humid air into liquid water through heat exchange, and then removes the water through discharge or evaporation to achieve the purpose of drying the air. The following is a detailed analysis of the air dryer heat exchanger:

Recommended Products

Recently Viewed

Good Quality Air Dryer Exchanger All Famous Brands Replacement Spare Parts Plate Heat Exchangers

Good Quality Air Dryer Exchanger All Famous Brands Replacement Spare Parts Plate Heat Exchangers China Factory Air Dryer Exchanger All Famous Brands Replacement Spare Parts Plate Heat Exchangers

China Factory Air Dryer Exchanger All Famous Brands Replacement Spare Parts Plate Heat Exchangers Cooler,Heat Exchanger,Oil Cooler

Cooler,Heat Exchanger,Oil Cooler Stainless Steel Condenser for Distillation, Cooling, and Heat Recovery Processes

Stainless Steel Condenser for Distillation, Cooling, and Heat Recovery Processes High-Accuracy Air Dryer Exchanger All Famous Brands Replacement Spare Parts Plate Heat Exchangers

High-Accuracy Air Dryer Exchanger All Famous Brands Replacement Spare Parts Plate Heat Exchangers

Contact Us

GUANGDONG Y.K.R NEW ENERGY CO.,LTD.