Welcome!

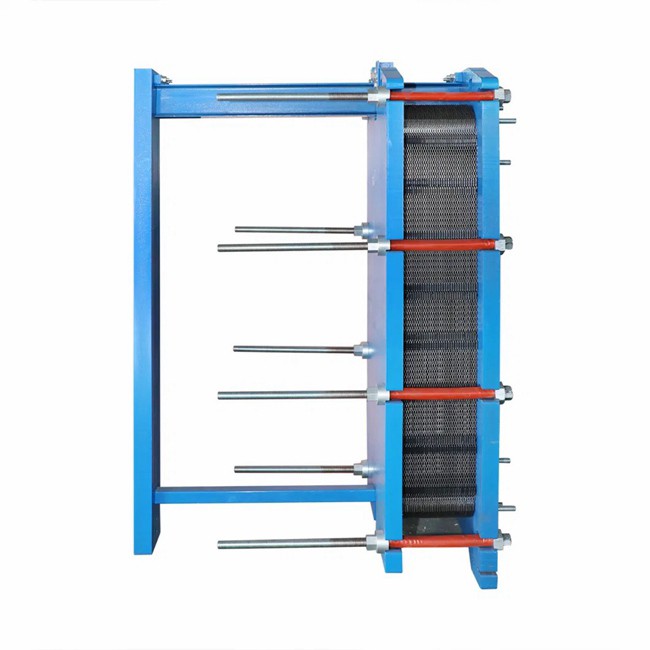

High Pressure Brazed Plate Heat Exchanger for Air Dryers

Product Description

Application fields of plate heat exchangers

Refrigeration system: used for plate condenser and plate evaporator.

HVAC: Intermediate heat exchangers used in conjunction with boilers, high-rise building intermediate heat exchangers, etc.

Chemical industry: used for heating, cooling, evaporation concentration, condensation, etc. in processes such as soda ash industry, synthetic ammonia, and alcohol fermentation.

Solar energy utilization: Participate in the heat exchange process of heat transfer media such as ethylene glycol and antifreeze in solar collector panels.

Steel industry: cooling quenching oil, cooling electroplating solution, etc.

Food industry: sterilization and cooling of salt, dairy products, soy sauce, vinegar, heating and cooling of animal and vegetable oils, etc.

Textile industry: various waste liquid heat recovery, cooling of boiling phosphating fibers, etc.

Paper industry: Heating and cooling of cooling black water and bleaching saline alkali solution.

Central heating: Heating of waste heat areas in thermal power plants, heating of domestic water, etc.

Plate heat exchanger is an efficient, compact, and flexible heat exchange device that has been widely used in multiple fields. However, it is also necessary to pay attention to its drawbacks and take corresponding measures to prevent it during use. There are two main types of plate heat exchangers: frame type (detachable) and brazed type. There are three types of plate forms: herringbone corrugated plate, horizontal flat corrugated plate, and nodular plate. These different types of plate heat exchangers have their own characteristics and are suitable for different working conditions and media.

The working principle of plate heat exchangers mainly includes three processes: heat transfer, mass transfer, and resistance. Cold and hot fluids flow through both sides of the plate heat exchanger, with the hot fluid releasing heat on the hot side plate and the cold fluid absorbing heat on the cold side plate, thereby achieving heat transfer. Heat is mainly transferred through convection and conduction. In addition, plate heat exchangers can also achieve mass transfer processes by adding appropriate fillers or membranes to transfer substances between the fluids on both sides.

Air dryer heat exchangers are widely used in various fields, such as industrial manufacturing, food processing, pharmaceutical and chemical industries, textile printing and dyeing, etc. In these fields, air dryer heat exchangers play a crucial role in ensuring smooth production processes and stable product quality.

The heat exchanger in an air dryer is an important component that mainly condenses the moisture in humid air into liquid water through heat exchange, and then removes the water through discharge or evaporation to achieve the purpose of drying the air. The following is a detailed analysis of the air dryer heat exchanger:

Recommended Products

Recently Viewed

Good Quality Air Dryer Exchanger All Famous Brands Replacement Spare Parts Plate Heat Exchangers

Good Quality Air Dryer Exchanger All Famous Brands Replacement Spare Parts Plate Heat Exchangers China Factory Air Dryer Exchanger All Famous Brands Replacement Spare Parts Plate Heat Exchangers

China Factory Air Dryer Exchanger All Famous Brands Replacement Spare Parts Plate Heat Exchangers Cooler,Heat Exchanger,Oil Cooler

Cooler,Heat Exchanger,Oil Cooler Stainless Steel Condenser for Distillation, Cooling, and Heat Recovery Processes

Stainless Steel Condenser for Distillation, Cooling, and Heat Recovery Processes High-Accuracy Air Dryer Exchanger All Famous Brands Replacement Spare Parts Plate Heat Exchangers

High-Accuracy Air Dryer Exchanger All Famous Brands Replacement Spare Parts Plate Heat Exchangers

Contact Us

GUANGDONG Y.K.R NEW ENERGY CO.,LTD.