Welcome!

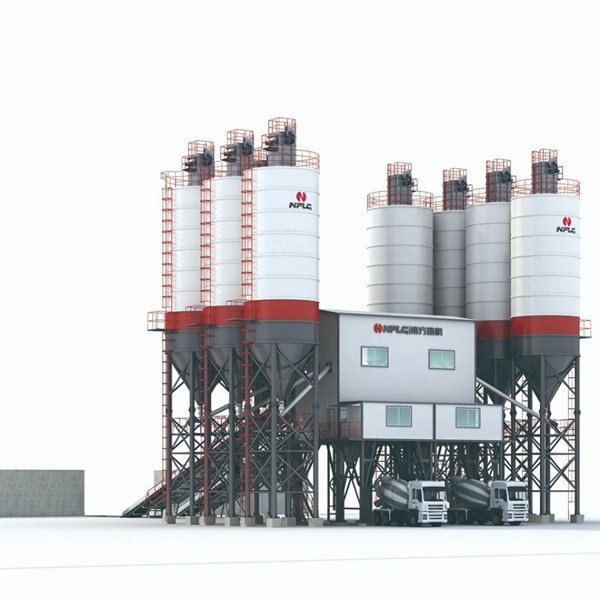

China Manufacturer Engineering Construction Machinery Concrete Mixing Plant Concrete Batching Plant for Sale

Product Description

In the busy world of architecture, time and precision are crucial, and concrete mixing plants are unsung heroes. These industrial scale facilities are the backbone of modern infrastructure development, providing the necessary concrete for everything from residential buildings to towering skyscrapers. In this article, we delve into the world of concrete mixing plants, exploring their significance, operations, and innovative technologies driving them.

Site selection for concrete mixing plant

Service radius: It should be close to the place where the goods are sold and used, and the service radius is generally 50-100 kilometers.

Road transportation conditions: Good road transportation standards should be established to reduce transportation costs and congestion frequency.

Power and water sources: It should be close to high-voltage power sources and sufficient water sources to ensure production needs.

Venue conditions: There should be sufficient factory premises and consideration should be given to the impact of terrain and topography on equipment installation.

The concrete mixing plant mainly consists of the following five systems and other ancillary facilities:

Mixing host: It is the core equipment of a concrete mixing plant, responsible for mixing and blending various raw materials.

Material weighing system: used for precise weighing of various raw materials to ensure the accuracy of concrete mix proportions.

Material conveying system: responsible for conveying various raw materials to the mixing host.

Material storage system: used for storing raw materials such as cement, sand, stone, etc.

Control system: Automatically control the entire mixing plant to ensure the smooth progress of the production process.

A concrete mixing plant, also known as a precast concrete yard, is a combined device used for centralized mixing of concrete. Due to its high degree of mechanization and automation, it has high production efficiency and can ensure the quality of concrete and save cement. It is commonly used in large and medium-sized water conservancy, power, bridge and other projects with large concrete engineering quantities, long construction periods, and concentrated construction sites. Self dumping mixing plant and forced mixing plant. The self dumping mixing plant uses the method of pouring and dropping to mix materials, which is suitable for concrete with good fluidity; The forced mixing plant uses rotating mixing blades to forcibly mix materials, suitable for various flowability and compactness of concrete.

Recommended Products

Recently Viewed

China Factory Fixed Cement Concrete Concrete Batching Mixing Plant Stationary Machine Manufacturers for Sale

China Factory Fixed Cement Concrete Concrete Batching Mixing Plant Stationary Machine Manufacturers for Sale China Supplier Fixed Cement Concrete Batching Mixing Plant for Sale

China Supplier Fixed Cement Concrete Batching Mixing Plant for Sale China Factory Drawing Stationary Ready Mixed Concrete Batching Mixing Plant with Good Price

China Factory Drawing Stationary Ready Mixed Concrete Batching Mixing Plant with Good Price China Manufacturer Fixed Cement Concrete Concrete Batching Mixing Plant Stationary Machine Manufacturers for Sale

China Manufacturer Fixed Cement Concrete Concrete Batching Mixing Plant Stationary Machine Manufacturers for Sale China Manufacturer Engineering Construction Machinery Concrete Mixing Plant Concrete Batching Plant for Sale

China Manufacturer Engineering Construction Machinery Concrete Mixing Plant Concrete Batching Plant for Sale

Contact Us

Dongyue Machinery Group Co., Ltd.