Welcome!

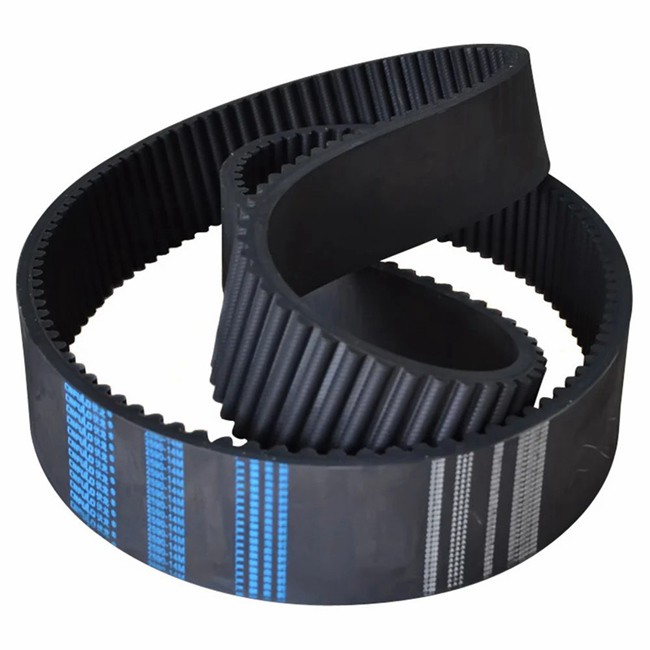

Customized Industrial Rubber Timing Belt Htd

Product Description

Rubber synchronous belts are widely used in applications that require high-speed, high load, and high-precision transmission, such as automobiles, textiles, machine tools, office machinery, power tools, instruments, and food packaging machinery, due to their high precision, high stability, and wear resistance. In addition to its structural and transmission characteristics, it also has good dynamic flexibility, good crack resistance, excellent ozone performance, aging resistance, heat resistance, oil resistance, wear resistance and other features. These characteristics enable rubber synchronous belts to maintain good performance even in complex environments.

The rubber synchronous belt is composed of rubber toothed belt and glass fiber reinforced material, with a skeleton material embedded inside to enhance tensile strength, and a precise tooth profile formed on the surface for meshing and transmission with the belt teeth groove. Adopting gear transmission method, power transmission is achieved through precise meshing of tooth profile and belt tooth groove, ensuring the accuracy and synchronization of transmission ratio. It has high transmission accuracy and stability, can achieve precise transmission ratio and synchronous motion, and is suitable for occasions with high requirements for transmission accuracy.

Product Features

High efficiency: The transmission efficiency of synchronous belts is relatively high, usually reaching over 98%, far higher than traditional belt transmission.

Accuracy: Due to the close fit between teeth and grooves, synchronous belts can ensure the accuracy of transmission and reduce errors.

Wear resistance: Synchronous belts are usually made of rubber and reinforced materials, which have good wear resistance and can extend their service life.

Low noise: The toothed design of the synchronous belt helps reduce noise during transmission and improve the comfort of the working environment.

High load capacity: Some synchronous belts are embedded with tensile materials such as steel wires or Kevlar cables, which can withstand high loads.

Due to the use of high-quality rubber materials and reasonable design, rubber synchronous belts have good dynamic bending performance and can adapt to various complex transmission environments. Through precise tooth meshing, rubber synchronous belts can achieve efficient transmission and reduce energy loss. Rubber synchronous belt can ensure the accuracy of transmission ratio and meet the requirements of high motion accuracy in situations. Rubber synchronous belts usually have good oil and high temperature resistance, and can work stably in harsh working environments.

Rubber synchronous belt is a type of transmission belt made of rubber material, which is embedded with a skeleton material (such as fiberglass) inside and forms a precise tooth shape on the outer surface to mesh with the belt teeth for transmission. Rubber synchronous belt is an efficient, precise, and durable transmission component widely used in various mechanical equipment, providing important support for the development of modern industry.

Recommended Products

Recently Viewed

Contact Us

Zhoushan AIWO Auto Spare Parts Co., Ltd.