Welcome!

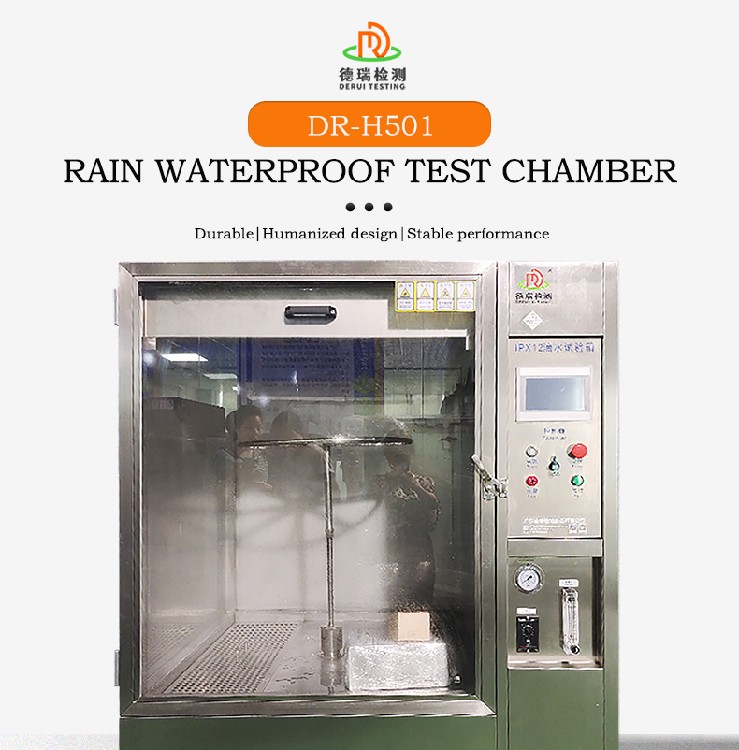

Adjustable Drenching Rain Test Chamber for Customized Testing Needs

Product Description

STANDARD FEATURES

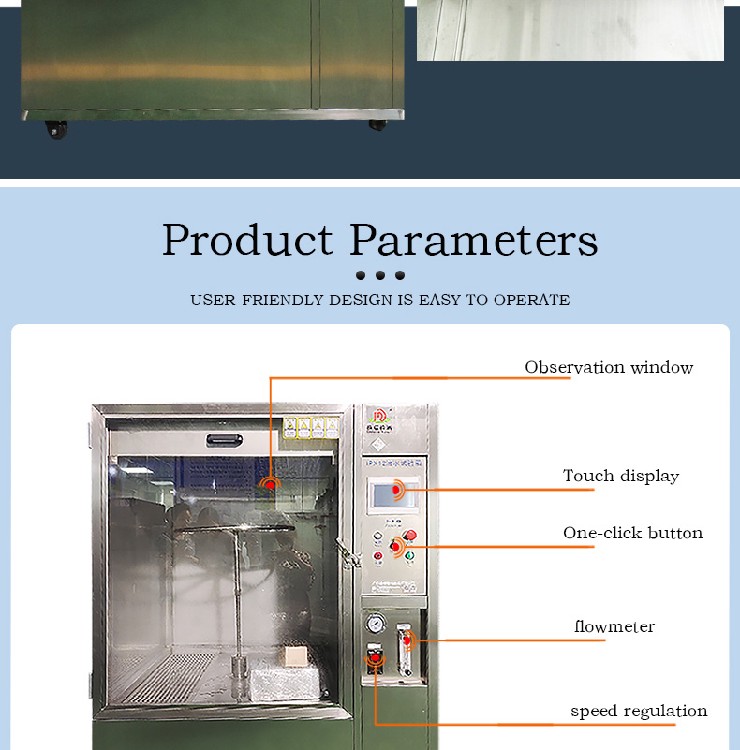

| Item | Specification |

| Internal dimension | (W*D*H)1000*1000*1000mm |

| External dimension | (W*D*H)1300*1100*1700mm |

| Oscillating tube | Radius 400mm |

| Oscillating angle | IPX3: spray ±60° from vertical line to each side, total 120°IPX4: spray ±180° from vertical line to each side, total 360° |

| Oscillating speed | IPX3: 2*120° for 4sIPX4: 2*360° for 12s |

| Spray nozzle | Diameter: 0.4mm, removableEnsure the water sprays in a line and without tolerance |

| Distance between two nozzles | 50mm |

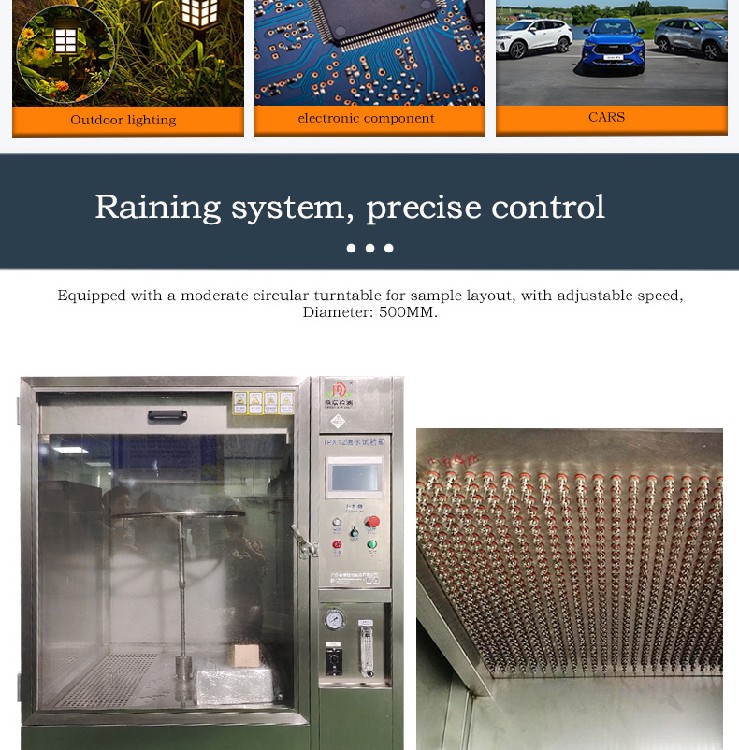

| Turntable dimension | 500mm |

| Turntable rotation speed | 1-3 cycles/min |

| Water flow of each nozzle | 0.07 L/min +5% |

| Test duration | 1~999,999min, adjustable |

| Pressure gauge | 80-150Kpa |

| Material | Chamber - Stainless steel ; Spray nozzle - Brass |

Product Advantages of Rainfall Tester

Highly accurate simulation ability: The rainfall test chamber can realistically reproduce various rainfall scenarios, from fine drizzle to torrential downpour, all of which can be accurately simulated. At the same time, the equipment can accurately control the amount of rain, the size of raindrops and rainfall time.

Convenient operation: Equipped with an intelligent control system, it makes it easy for operators to get started without tedious training. Just simply set the parameters, the test chamber can run automatically, which greatly improves the working efficiency.

Strong stability: the use of high-quality materials and advanced manufacturing technology ensures that the equipment maintains stable performance over a long period of time. Good sealing can prevent rainwater leakage, ensuring the safety and reliability of the test.

Multifunctionality: applicable to a variety of industries, such as electronic and electrical engineering, aerospace, other scientific research units external lighting, signaling devices and automotive lamps and lanterns shell protection test detection.

Visualization design: large visual glass door is convenient for observing the condition of the tested samples in the test chamber, which is convenient for users to monitor the experimental process in real time.

High degree of automation: it has a history memory function (can query the history of the test record within 7 days), and can display the temperature and humidity curve, support 270 degrees of the pendulum pipe and 360 degrees of the rotating rod water spray device and adjustable speed of the sample stage.

Installation Requirements

Space Preparation: Choose a large enough space to place the rain test chamber, and take into account the need to have enough space around for maintenance and operation.

Environmental conditions: The installation location should be protected from direct sunlight, away from heat and vibration sources, and ensure that the ambient temperature is between 5°C and +28°C and the relative humidity does not exceed 85%.

Power Connection: Connect the power supply correctly according to the electrical specifications provided by the manufacturer, and complete the electrical connection work by a professional electrician to ensure safety.

Water access: If the equipment requires water supply, it needs to be connected to a clean water source and the proper water pressure should be adjusted according to the manufacturer's instructions.

Drainage system: As a large amount of water will be generated during the testing process, proper drainage facilities are required to dispose of the waste water.

Floor Leveling: The floor of the installation location must be level and firm to support the weight of the chamber and prevent it from shifting during use.

Exhaust device: If equipped with an exhaust device, it must be installed correctly according to the instructions to ensure that moisture can be effectively discharged.

Recommended Products

Recently Viewed

Building Material Vertical Combustion Tester, Ensuring Fire Safety

Building Material Vertical Combustion Tester, Ensuring Fire Safety Vertical Combustion Tester, Features Automatic Data Recording and Analysis

Vertical Combustion Tester, Features Automatic Data Recording and Analysis Desktop 4-Channel Optical Power Meter WG3024 Stable Performance for Transceiver Production Test

Desktop 4-Channel Optical Power Meter WG3024 Stable Performance for Transceiver Production Test Industrial Grade WG3028 High Speed 8-Channel OPM InGaAs Detector Optional

Industrial Grade WG3028 High Speed 8-Channel OPM InGaAs Detector Optional Vertical Combustion Tester, Providing Reliable Testing Results for Research and Development

Vertical Combustion Tester, Providing Reliable Testing Results for Research and Development

Contact Us

Guangdong Derui Testing Equipment Co., Ltd.