Welcome!

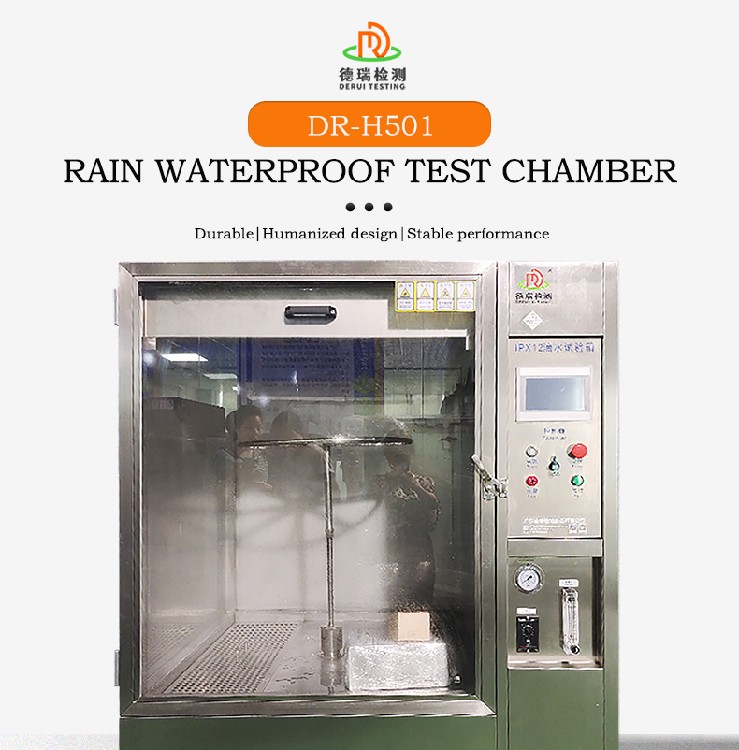

Drenching Rain Test Chamber for Electronic Devices Waterproof Testing

Product Description

STANDARD FEATURES

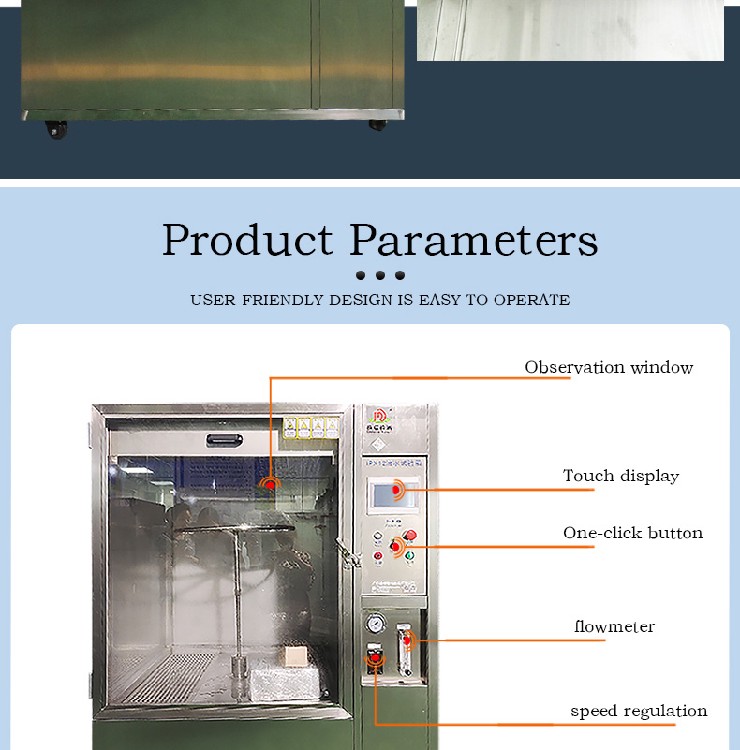

| Item | Specification |

| Internal dimension | (W*D*H)1000*1000*1000mm |

| External dimension | (W*D*H)1300*1100*1700mm |

| Oscillating tube | Radius 400mm |

| Oscillating angle | IPX3: spray ±60° from vertical line to each side, total 120°IPX4: spray ±180° from vertical line to each side, total 360° |

| Oscillating speed | IPX3: 2*120° for 4sIPX4: 2*360° for 12s |

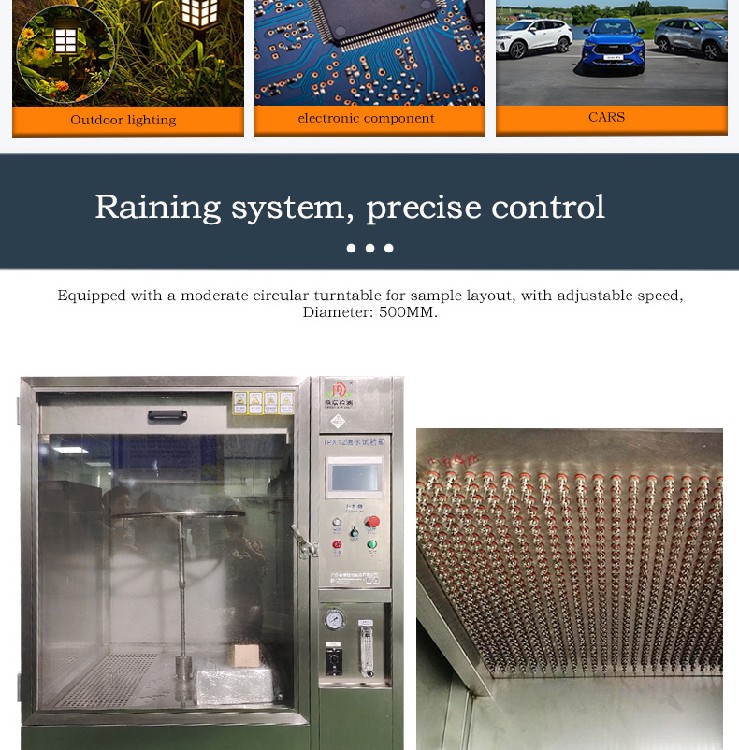

| Spray nozzle | Diameter: 0.4mm, removableEnsure the water sprays in a line and without tolerance |

| Distance between two nozzles | 50mm |

| Turntable dimension | 500mm |

| Turntable rotation speed | 1-3 cycles/min |

| Water flow of each nozzle | 0.07 L/min +5% |

| Test duration | 1~999,999min, adjustable |

| Pressure gauge | 80-150Kpa |

| Material | Chamber - Stainless steel ; Spray nozzle - Brass |

The rainfall test chamber is used to simulate the natural rainfall environment and test the weather resistance and waterproof performance of products under different rainfall conditions. The following are the general steps for operating the rainfall tester:

Preparation:

Confirm that the equipment has been properly installed and connected to the power and water sources.

Check whether the inside of the equipment is clean and free of foreign matter, and ensure that the drainage system is smooth.

Sample preparation and placement:

Prepare the samples to be tested according to the test requirements.

Place the sample correctly in the test chamber, be careful not to let the sample touch the nozzle or affect the distribution of water.

Parameter setting:

Set the corresponding test parameters according to the test standards or requirements, including but not limited to rainfall intensity, test time, temperature, etc.

Set the pendulum angle (if any) and sample table speed (if applicable) to achieve the desired rainfall coverage and uniformity.

Initiate the test:

Close the door of the test chamber to ensure a good seal.

Start the equipment to begin the rainfall test, during which the equipment's operating status should be monitored to ensure that everything is in order.

Monitoring and Recording:

Regularly check and record relevant data during the test, such as water temperature, rainfall, test duration etc.

If the equipment supports, you can use its own data recording function to automatically save the key parameters during the test.

End the test:

After reaching the scheduled test time, stop the equipment operation.

Open the door of the test chamber, remove the sample and turn off the water and power supply.

Cleanup:

Clean the interior of the test chamber to remove standing water and possible residual stains.

Perform follow-up inspection and evaluation of samples and record analysis results.

Maintenance:

Perform regular maintenance on the equipment, including cleaning filters, checking piping for clogging, and verifying that electrical connections are secure, to ensure long-term stable operation.

Recommended Products

Recently Viewed

Building Material Vertical Combustion Tester, Ensuring Fire Safety

Building Material Vertical Combustion Tester, Ensuring Fire Safety Vertical Combustion Tester, Features Automatic Data Recording and Analysis

Vertical Combustion Tester, Features Automatic Data Recording and Analysis Desktop 4-Channel Optical Power Meter WG3024 Stable Performance for Transceiver Production Test

Desktop 4-Channel Optical Power Meter WG3024 Stable Performance for Transceiver Production Test Industrial Grade WG3028 High Speed 8-Channel OPM InGaAs Detector Optional

Industrial Grade WG3028 High Speed 8-Channel OPM InGaAs Detector Optional Vertical Combustion Tester, Providing Reliable Testing Results for Research and Development

Vertical Combustion Tester, Providing Reliable Testing Results for Research and Development

Contact Us

Guangdong Derui Testing Equipment Co., Ltd.