Welcome!

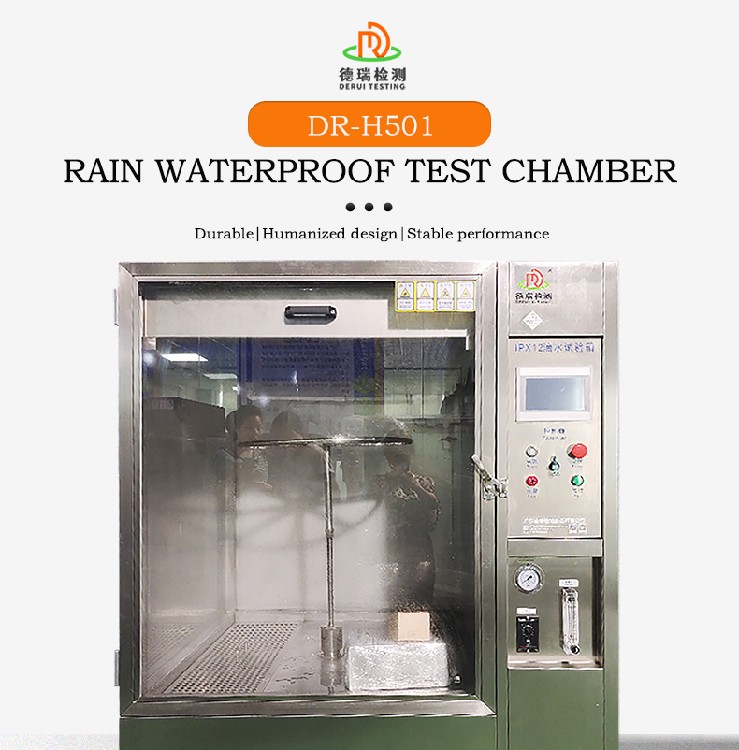

Drenching Rain Test Chamber for Lighting Fixtures Weatherproof Testing

Product Description

Drenching Rain Test Chamber for Lighting Fixtures Weatherproof Testing STANDARD FEATURES

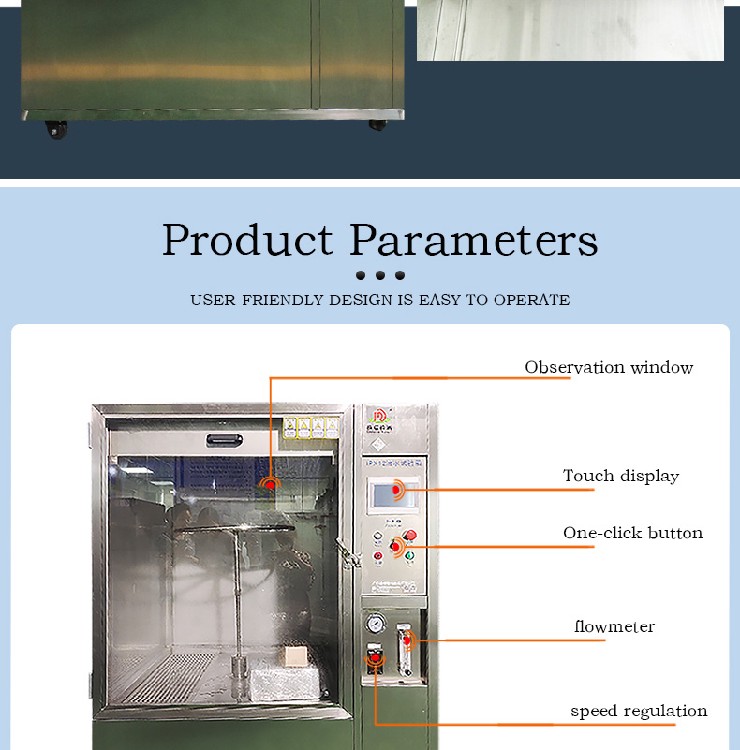

| Item | Specification |

| Internal dimension | (W*D*H)1000*1000*1000mm |

| External dimension | (W*D*H)1300*1100*1700mm |

| Oscillating tube | Radius 400mm |

| Oscillating angle | IPX3: spray ±60° from vertical line to each side, total 120°IPX4: spray ±180° from vertical line to each side, total 360° |

| Oscillating speed | IPX3: 2*120° for 4sIPX4: 2*360° for 12s |

| Spray nozzle | Diameter: 0.4mm, removableEnsure the water sprays in a line and without tolerance |

| Distance between two nozzles | 50mm |

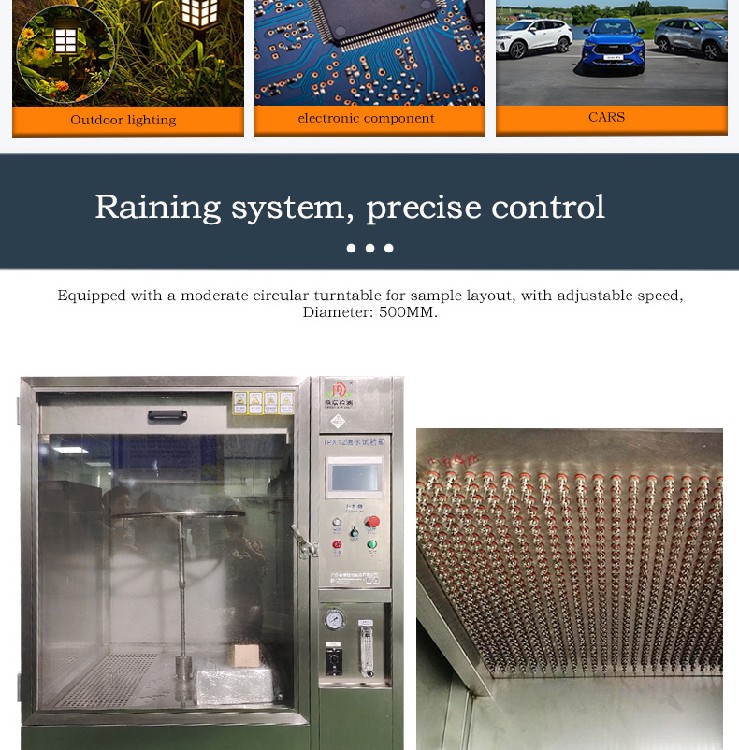

| Turntable dimension | 500mm |

| Turntable rotation speed | 1-3 cycles/min |

| Water flow of each nozzle | 0.07 L/min +5% |

| Test duration | 1~999,999min, adjustable |

| Pressure gauge | 80-150Kpa |

| Material | Chamber - Stainless steel ; Spray nozzle - Brass |

Drenching rain test chamber in the use of the process may encounter a variety of failures, the following are some common failures and their solutions:

The equipment is not energized:

Check whether the power supply is normal, and make sure that the voltage and current meet the requirements of the equipment.

Confirm whether the phase sequence is correct, and whether there is a zero line connection. If necessary, adjust the phase sequence or access the zero line.

Pendulum does not move:

Check whether the parameter settings are correct and make necessary adjustments.

Verify that the pendulum motor is working properly, and if faults are found, replace or repair the motor.

Turntable does not rotate:

Check the parameter settings and make sure that the parameters such as rotary speed and time of the turntable are set correctly.

Check the working condition of the turntable motor and repair or replace it if necessary.

No water spray or abnormal water spray:

Check whether the water pressure is normal and adjust it to the specified range.

Check whether the water pump is working properly, if found problems then repair or replace the pump.

Clear or replace clogged nozzles to ensure unobstructed water flow.

Clogged water jets:

Use purified water for testing to minimize scale formation.

Dust the sample before testing to avoid impurities entering the water supply.

If the nozzle is slightly clogged, it can be cleared with a through needle; severe clogging may require replacement of the nozzle.

Water flow is too high:

Adjust water pressure to return to proper level.

Abnormal temperature or humidity control (for equipment with temperature and humidity control):

Check temperature and humidity sensors and control systems for proper function and calibrate or replace parts.

Refrigeration system malfunction (if this system is present):

Check for refrigerant leaks or insufficiency and check the operating condition of the compressor, replenish refrigerant or repair compressor if necessary.

Electrical system problems:

Check the security of power cords and electrical components, make sure all connections are secure and show no signs of deterioration, and replace damaged parts if necessary.

Deterioration of sealing performance:

Regularly check the seal of the test chamber to ensure that it is in good condition to prevent outside air from entering and affecting the test results.

To ensure the long-term stable operation of the drenching test chamber, attention should also be paid to routine maintenance measures, such as regular cleaning, lubrication of the transmission mechanism, checking the drainage system. If you encounter complex or unable to solve the problem by yourself, it is recommended to contact professional technicians or equipment suppliers for help.

Recommended Products

Recently Viewed

Building Material Vertical Combustion Tester, Ensuring Fire Safety

Building Material Vertical Combustion Tester, Ensuring Fire Safety Vertical Combustion Tester, Features Automatic Data Recording and Analysis

Vertical Combustion Tester, Features Automatic Data Recording and Analysis Desktop 4-Channel Optical Power Meter WG3024 Stable Performance for Transceiver Production Test

Desktop 4-Channel Optical Power Meter WG3024 Stable Performance for Transceiver Production Test Industrial Grade WG3028 High Speed 8-Channel OPM InGaAs Detector Optional

Industrial Grade WG3028 High Speed 8-Channel OPM InGaAs Detector Optional Vertical Combustion Tester, Providing Reliable Testing Results for Research and Development

Vertical Combustion Tester, Providing Reliable Testing Results for Research and Development

Contact Us

Guangdong Derui Testing Equipment Co., Ltd.