Welcome!

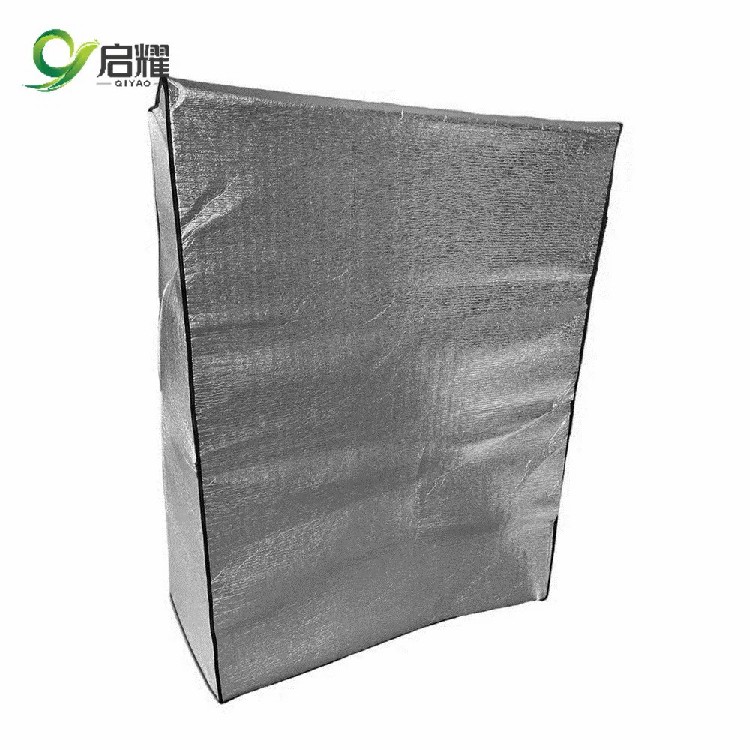

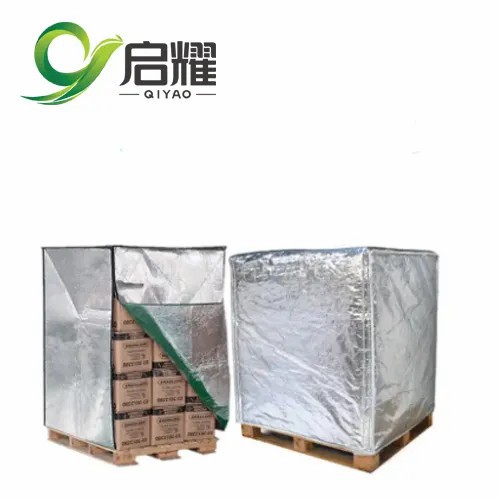

Manufacturers wholesale pallet insulation packaging suitable for logistics

Basic Info

| Certificates | ROHS,MSDS,REACH | Compression strength | 214 KPA | Density | 380 kg/m³ |

|---|---|---|---|---|---|

| MOQ | m2 | Package | Woven Fabric Bag/Carton | Puncture strength | 19 N GB/T 37608-2019 |

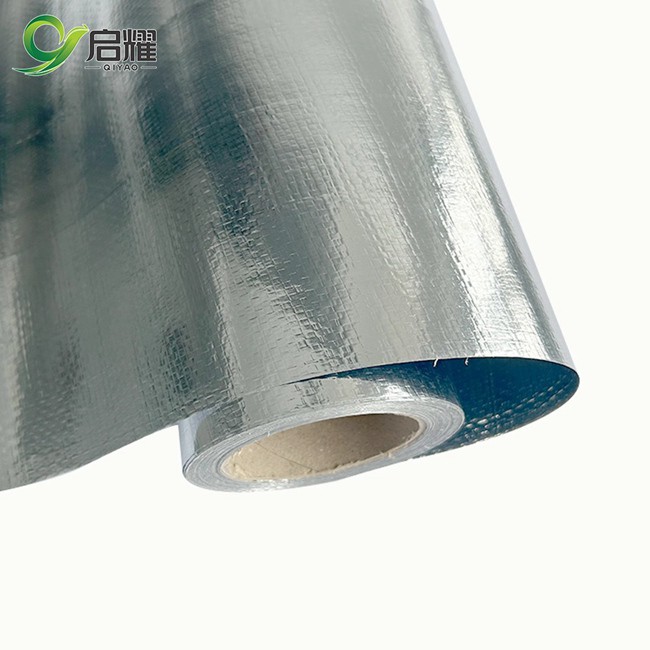

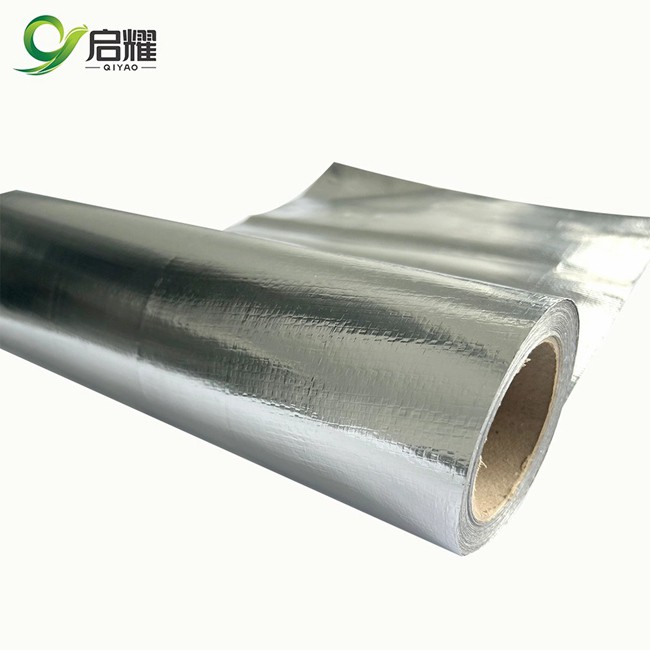

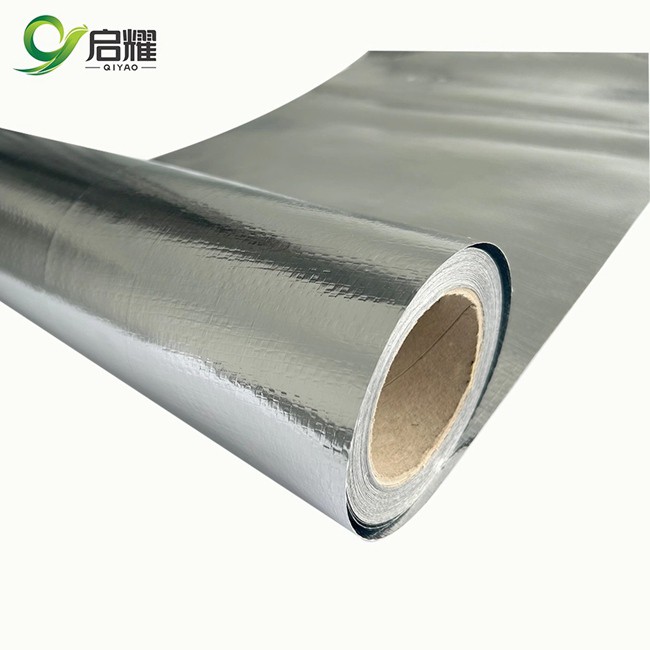

| Size | 400x600 or customized | Size Tolerance for Length&Width | ±5mm | Structure | Foil+Fiberglass+Foil |

| Surface water absorption | 80 GSM | Thermal Conductivity | < 0.0035,25ºC GB/T 37608-2019 | Thickness | 5-50mm or customized |

Product Description

Introduction

Pallet insulation packaging is a specialized thermal solution designed to protect temperature-sensitive goods during storage and transportation. These systems maintain consistent internal temperature, shielding products from external temperature fluctuations, humidity, and physical shocks. Constructed with high-performance insulating materials such as polyurethane foam, expanded polystyrene (EPS), or vacuum-insulated panels (VIPs), pallet insulation packaging is often combined with phase change materials (PCMs) or dry ice to achieve precise temperature control.

Our company’s pallet insulation packaging is modular and customizable, which is compatible with standard pallet sizes to ensure seamless integration with global logistics systems. It serves as a critical tool for industries requiring cold chain compliance, such as pharmaceuticals, food, beverage, and biotechnology.

Performance

1. Superior Thermal Performance

Insulation materials with low thermal conductivity (e.g., VIPs at 0.004 W/m·K) create a heat transfer barrier, maintaining temperature between -80°C and +25°C for extended durations.

PCMs or gel packs enhance temperature stability without relying on external power sources.

2. Robust Product Protection

Combine thermal insulation with shock-absorbing layers to safeguard fragile items like vaccines or electronics.

Waterproof and airtight designs prevent moisture ingress, which is crucial for hygroscopic products.

3. Sustainability and Reusability

Modern systems utilize recyclable materials (e.g., biodegradable EPS) or are designed for multiple uses, reducing waste and operational costs.

Lightweight designs minimize carbon footprints during transportation.

4. Customization and Flexibility

Tailor to fit specific pallet dimensions, product shapes, and temperature requirements.

Modular components enable easy assembly and disassembly, adapting to varying shipment sizes.

5. Cost Efficiency

Eliminate the need for costly refrigerated transport in many scenarios.

Reduce product loss due to spoilage and ensure compliance with regulatory standards (e.g., FDA, EU GDP).

Applications

1. Pharmaceuticals and Biotechnology

Ensure safe transportation of vaccines, biologics, and lab samples within strict temperature ranges (e.g., 2–8°C for mRNA vaccines).

Comply with WHO guidelines and GDP standards for cold chain logistics.

2. Food and Beverage

Preserve freshness of perishables such as seafood, dairy, and frozen meals during long-haul shipments.

It is ideal for direct-to-consumer meal kits or gourmet ingredient deliveries.

3. Chemical and Industrial Products

Protect temperature-sensitive chemicals, adhesives, or electronic components from thermal degradation.

4. E-commerce and Cold Chain Logistics

Support last-mile delivery of temperature-critical goods, including premium chocolates or floral arrangements.

5. Emergency and Humanitarian Aid

Facilitate transportation of medical supplies and vaccines to remote areas lacking reliable refrigeration.

Why choose QIYAO?

QIYAO has grown into a diversified manufacturing and distribution company with sales and distribution centers throughout China. The company mainly sells building roof waterproof materials and aluminum foil reflective materials, applied heat insulation and moisture-proof materials, steel structure roof joint insulation materials and composite panels, cold chain logistics systems or bags of plastic raw materials and insulation cover accessories and other four market segments, more than 3,000 products are sold to more than 5,000 customers around the world.

We pride ourselves on high quality products, short lead times and the highest level of customer service. We have a dedicated technical department to support product development and quality control.

Located in Hangzhou, China, the factory has high-speed automatic laminating machine, foaming machine and heat sealing machine production lines to ensure high production capacity and strict quality control.

If you choose QIYAO, you are not only choosing the technical performance of our products, but also choosing an interlocutor who will work with you to find the right solution for your project.

Recommended Products

Recently Viewed

New reusable foam EPE Insulated Tray Covers

New reusable foam EPE Insulated Tray Covers Suppliers sell Hot tray cover insulation material directly

Suppliers sell Hot tray cover insulation material directly Thermal Pallet Cover: Ultimate Protection for Temperature-Sensitive Shipments

Thermal Pallet Cover: Ultimate Protection for Temperature-Sensitive Shipments Thermal Pallet Cover: Smart, Sustainable, and Secure Shipping Protection

Thermal Pallet Cover: Smart, Sustainable, and Secure Shipping Protection Thermal Pallet Cover: Advanced Temperature Control for Safe and Efficient Shipping

Thermal Pallet Cover: Advanced Temperature Control for Safe and Efficient Shipping

Contact Us

Hangzhou Qiyao New Material Co., Ltd.