Welcome!

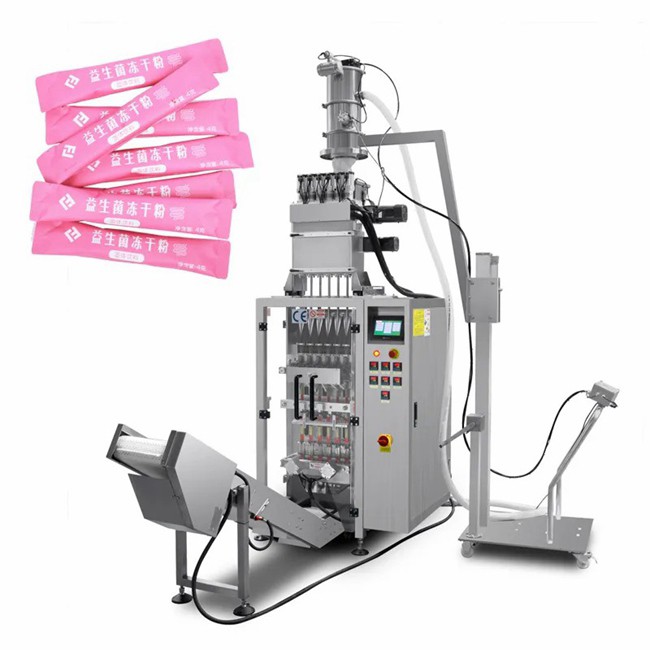

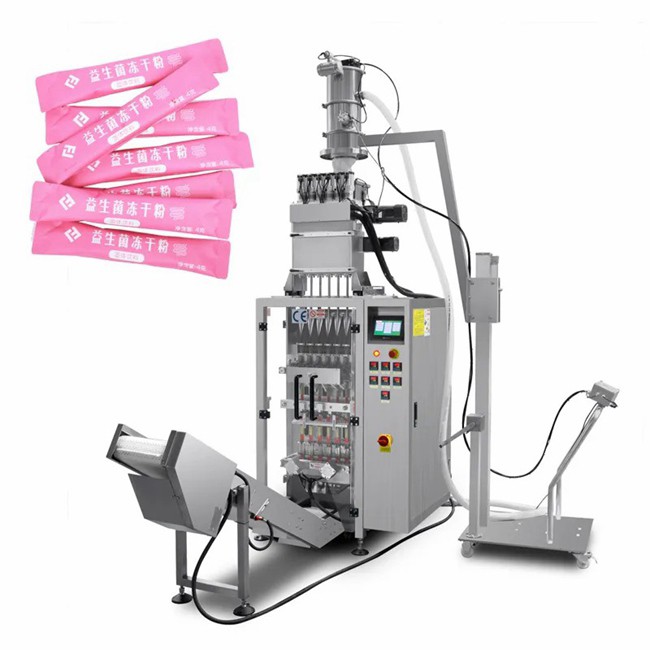

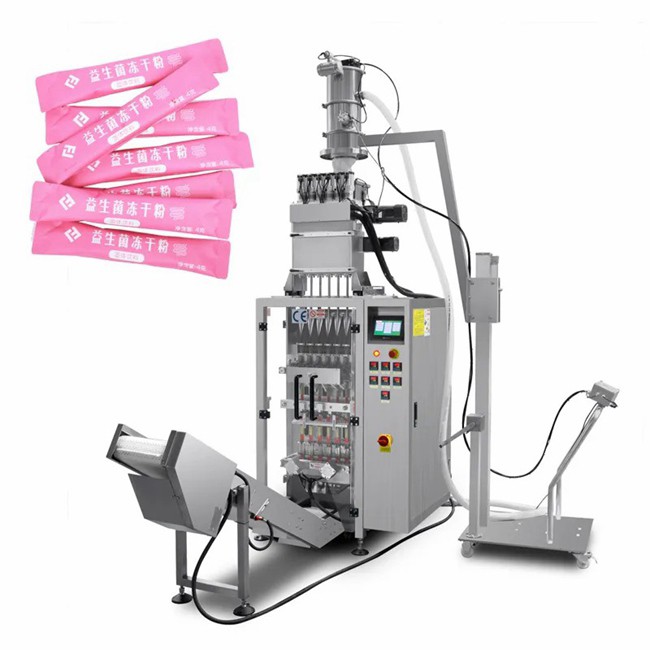

New automatic tea powder, coffee powder and milk powder packaging machine

Basic Info

| Driven Type | Pneumatic | Forming Function | Forming, Filling, Seal | Forming Species | Bag Moulding |

|---|---|---|---|---|---|

| HS Code | 842230 | Material | 304 Stainless Steel | Material Type | Grain |

| Max Film Width | 420mm | Name | Packing Machine | Packaging | Wooden |

| Packaging Material | Film | Power Voltage | 220V | Specification | 11 CBM |

| Speed | 30-50 Bags/Min/Lane | Transport Package | Wooden | Type | Filling and Sealing Machine |

Product Description

The global popularity of powdered teas from matcha and instant tea blends to functional herbal powders has surged and driven by their convenience, versatility, and rapid dissolution. Central to meeting this demand is the tea powder packing machine, a specialized system engineered to handle fine, dusty, or hygroscopic tea powders with accuracy, speed, and hygiene. These machines are critical for ensuring product integrity, minimizing waste, and maintaining the freshness that discerning consumers expect.

What Is a Tea Powder Packing Machine?

A tea powder packing machine is an automated solution designed to measure, fill, and seal powdered tea into pre-formed or custom-shaped packaging. Unlike standard tea bagging systems, these machines are tailored to manage the unique challenges of fine powders such as dust control, precise dosing, and prevention of clumping.

Key Features and Benefits

Dust-Free Operation

Tea powders, especially ultrafine varieties like matcha, generate significant dust during handling. Premium machines incorporate anti-static systems, vacuum suction, and enclosed filling zones to minimize airborne particles, ensuring a clean production environment and reducing product loss.

High Precision Dosing

Gravimetric fillers or auger-based systems deliver exact quantities (from 1 gram to 1 kilogram) with tolerances as tight as ±0.5%. This precision is vital for maintaining consistent product quality and compliance with labeling regulations.

Moisture and Oxygen Barrier

Many tea powders are sensitive to moisture and oxidation. Machines utilize multi-layered barrier films (e.g., aluminum foil or metallized PET) and nitrogen flushing options to extend shelf life and preserve flavor, color, and nutritional properties.

Versatile Packaging Formats

Adjustable jaws, forming tubes, and sealing heads allow quick transitions between packaging styles such as flat pouches, gusseted bags, or stick packs without major downtime. This flexibility caters to diverse markets from retail to foodservice.

Hygienic Design

Constructed with food-grade stainless steel and easy-to-clean surfaces, these machines meet stringent food safety standards (e.g., FDA, HACCP). Some models include CIP (Clean-in-Place) systems for sanitization without disassembly.

Sustainability Compatibility

Modern machines support eco-friendly materials like compostable films, recyclable paper laminates, or plant-based plastics, aligning with the growing demand for sustainable packaging solutions.

Why Choose a Tea Powder Packing Machine?

Investing in a dedicated tea powder packing system offers manufacturers:

Enhanced Product Quality: Consistent dosing and airtight sealing protect delicate flavors and bioactive compounds.

Increased Output: Speeds of up to 200 packs per minute enable rapid scaling to meet market demand.

Regulatory Compliance: Built-in traceability features (e.g., batch coding, QR printing) simplify compliance with food safety standards.

Cost Savings: Reduced material waste and labor dependency improve profit margins.

The Future of Tea Powder Packaging

As consumer preferences shift toward premium, functional, and sustainable products, tea powder packing machines are evolving to incorporate:

Biodegradable and Edible Packaging: Innovations in materials science enable eco-conscious formats.

Hyper-Customization: Digital printing allows small-batch and personalized packaging for niche markets.

Blockchain Traceability: Integration with blockchain systems to provide transparency in sourcing and production.

Recommended Products

Recently Viewed

Revolutionizing Packaging Efficiency: The Power of Plastic Packaging Machines

Revolutionizing Packaging Efficiency: The Power of Plastic Packaging Machines Efficient and Versatile Plastic Packaging Machines: Revolutionizing the Packaging Industry

Efficient and Versatile Plastic Packaging Machines: Revolutionizing the Packaging Industry Innovative Food Packaging Machines: Ensuring Freshness and Efficiency for Your Business

Innovative Food Packaging Machines: Ensuring Freshness and Efficiency for Your Business Unlocking the Future of Food Packaging: Revolutionizing Efficiency with Food Packaging Machines

Unlocking the Future of Food Packaging: Revolutionizing Efficiency with Food Packaging Machines Revolutionizing the Food Industry with Efficient Food Packaging Machines

Revolutionizing the Food Industry with Efficient Food Packaging Machines

Contact Us

Guangzhou Duoshun Machinery Co., Ltd.