Welcome!

Tree Debarkers: Stripping Bark for Efficiency and Value

Basic Info

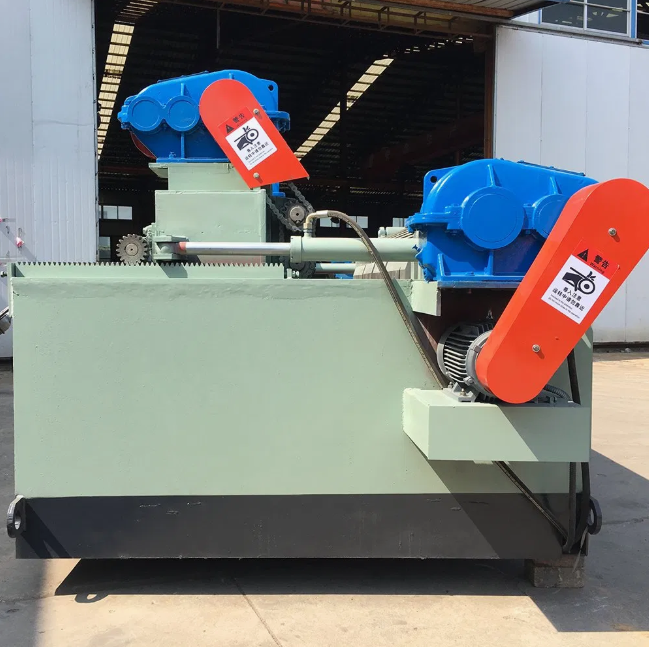

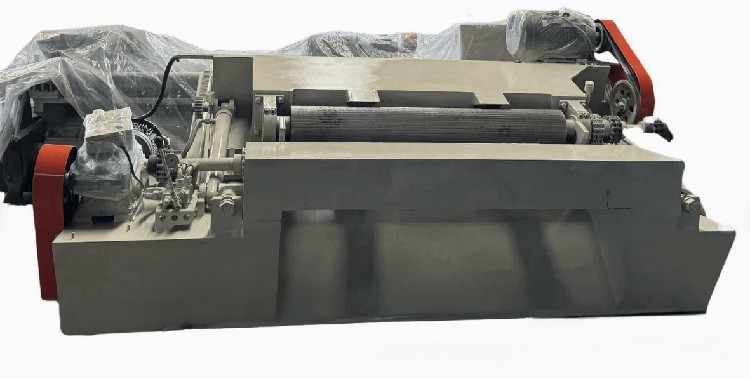

| Capacity | 5-10 Tons Per Hour | HS Code | 8465960000 | Log Diameter | 15-320mm |

|---|---|---|---|---|---|

| Model | 6000 | Motor | 37kw | Package Gross Weight | 13000.000kg |

| Package Size | 800.00cm * 200.00cm * 250.00cm | Specification | Customized | Trademark | Customized |

| Transport Package | Customized | Warranty | 1 Year | ||

Product Description

A tree debarker is a specialized forestry machine designed to efficiently remove bark from logs after felling. This crucial step in wood processing transforms rough logs into clean, bark-free timber ready for further milling, transport, or specific end-uses. Replacing labor-intensive and inconsistent manual methods, debarkers are vital for modern, high-volume forestry operations and wood processing facilities, enhancing productivity, quality, and profitability.

Primary Uses & Applications:

Sawmill Preparation: Essential before sawing logs into lumber to prevent bark (which often contains dirt, stones, and metal) from damaging expensive saw blades and reducing cut quality.

Pulp & Paper Production: Bark has different fiber properties and chemical composition than wood. Removing it ensures cleaner, higher-quality pulp for papermaking.

Veneer & Plywood Production: Provides a smooth, bark-free surface necessary for peeling or slicing high-quality veneer sheets.

Wood Chip Production (Biomass/Pulp): Produces cleaner chips with higher wood content and lower ash/mineral content (from embedded bark dirt) for better combustion efficiency (biomass energy) or pulp yield.

Pest & Disease Control: Removing bark helps eliminate insect larvae (e.g., bark beetles) and fungal spores that might be harbored within it, reducing the risk of infestation in storage or transport.

Improving Drying: Bark acts as a moisture barrier. Debarked logs dry faster and more uniformly, reducing drying time and energy costs.

Enhancing Appearance: Produces aesthetically cleaner logs for certain applications or markets.

Key Advantages of Using Debarkers:

Massive Labor Savings: Automates a historically slow, physically demanding, and hazardous manual task.

Increased Throughput & Efficiency: Processes logs at rates impossible manually (often tens or hundreds of cubic meters per hour).

Improved Product Quality: Produces cleaner, more consistent logs with minimal wood loss compared to manual methods.

Reduced Equipment Wear: Protects downstream processing equipment (saws, chipper knives, planers) from damage caused by bark-embedded contaminants.

Enhanced Safety: Minimizes worker exposure to sharp tools, repetitive strain injuries, and hazards associated with manual log handling.

Better Resource Utilization: Enables efficient processing of smaller diameter logs and residues that wouldn't be economical to debark manually.

Optimized Transport: Debarked logs weigh significantly less than bark-on logs, reducing transportation costs per unit of usable wood.

Efficiency & Performance:

Debarker efficiency is measured by:

Throughput: Volume (cubic meters) or number of logs processed per hour. High-capacity industrial machines can handle hundreds of cubic meters per hour.

Bark Removal Rate: How effectively and completely bark is stripped (ideally >95% clean).

Wood Loss: Minimizing the amount of valuable wood removed along with the bark. Modern machines are highly precise.

Log Size Range: The minimum and maximum log diameters and lengths a machine can effectively handle.

Automation Level: Integrated feed systems, sorting, and controls significantly boost overall line efficiency.

Factors affecting efficiency include log species (bark adhesion varies), bark condition (frozen, wet, thick), log shape (straight vs. crooked), and machine type/maintenance.

5 Key Questions & Answers About Tree Debarkers

Q: What are the main types of tree debarkers?

A: The three most common types are:

Drum Debarkers: Logs tumble inside a large rotating drum lined with abrasive surfaces or tools (like swinging hammers or knives). Good for lower-value pulpwood or small-diameter logs but can cause higher wood loss and log breakage.

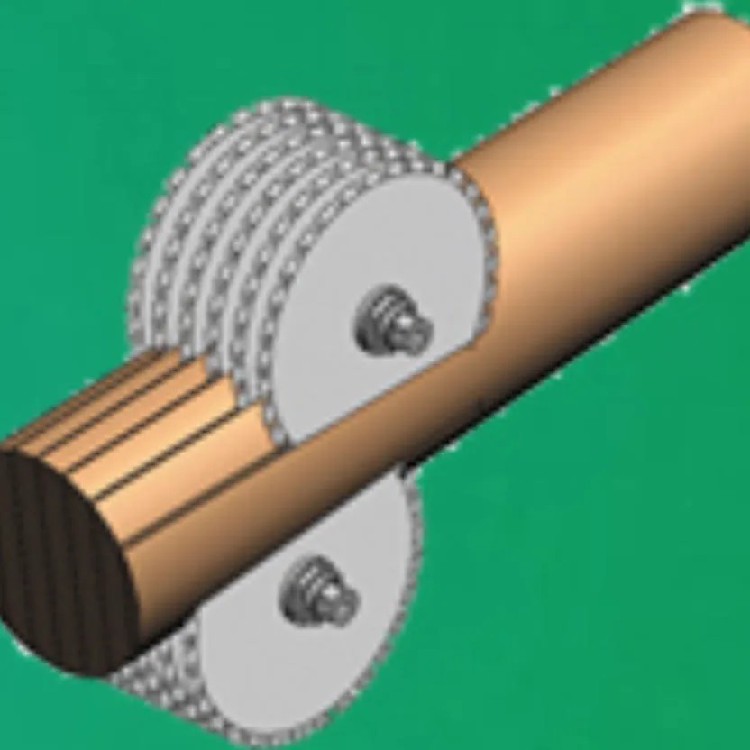

Ring Debarkers: Logs pass through a rotating ring equipped with multiple cutter arms or pressure shoes that contour to the log's shape. Highly efficient, precise (low wood loss), and suitable for a wide range of log sizes and values (sawlogs, veneer). Most common in modern sawmills.

Rotor Debarkers (Flail Debarkers): Feature a high-speed rotating rotor with swinging chains or hammers that strike the bark off. Effective for very dirty logs or removing thick, stubborn bark but can cause significant wood damage. Often used for lower-grade logs or biomass.

Q: Is debarking necessary for all wood products?

A: No, not always. While essential for sawmills, pulp/paper (kraft process), veneer, and clean chips, some products use bark-on wood:

Certain rustic construction elements (posts, beams).

Some landscape timbers.

Firewood (bark burns, though debarked wood burns cleaner).

Pulp produced using mechanical or semi-chemical processes (like TMP, CTMP) can sometimes tolerate more bark.

However, for the majority of industrial wood processing, debarking is a critical step.

Q: What are the main challenges or maintenance issues with debarkers?

A: Key challenges include:

Wear & Tear: Cutting knives, pressure shoes, hammers, and abrasive surfaces wear down rapidly due to friction with bark and embedded contaminants. Regular inspection, sharpening, and replacement are critical.

Contaminants: Stones, sand, and metal (e.g., old fencing wire) embedded in the bark cause significant damage to debarking tools and surfaces.

Log Variation: Handling logs of vastly different diameters, species (with varying bark properties), crookedness, and frozen/wet conditions can reduce efficiency and require machine adjustments.

Jams & Downtime: Improperly fed logs or mechanical failures can cause jams, leading to costly production stoppages. Robust feed systems and preventative maintenance are vital.

Q: Are there portable or small-scale debarkers?

A: Yes! While large stationary machines dominate industrial settings, options exist for smaller operations:

Portable Ring Debarkers: Mounted on trailers or skids, powered by PTO (from a tractor) or independent engines. Suitable for on-site processing by smaller sawmills or firewood producers.

Small Drum or Flail Debarkers: Designed for lower volumes of pulpwood or biomass.

PTO-Powered Roller Debarkers: Simpler machines using pressure rollers, often suitable for smaller logs or firewood production. These offer a more affordable entry point but may be less efficient or cause more wood loss than ring types.

Q: How does debarking contribute to sustainability in forestry?

A: Debarking enhances sustainability in several ways:

Reduced Waste: Enables efficient use of bark residues. The removed bark is often used as biomass fuel for on-site energy generation (reducing fossil fuel use) or as mulch/compost.

Improved Resource Efficiency: Minimizing wood loss during debarking means more usable wood from each harvested tree.

Cleaner Processing: Producing bark-free chips or pulp feedstock improves the efficiency and reduces the chemical load in downstream processes like pulping.

Pest Management: Helps prevent the spread of invasive insects and diseases transported under bark during log shipment.

Reduced Transport Emissions: Lighter debarked logs mean fewer truckloads or less fuel consumed per ton of usable wood transported.

Recommended Products

Recently Viewed

Unlocking Sustainable Forest Management with Advanced Forestry Machinery

Unlocking Sustainable Forest Management with Advanced Forestry Machinery Unlocking the Power of Forestry Machinery: Essential Tools for Sustainable and Efficient Forest Management

Unlocking the Power of Forestry Machinery: Essential Tools for Sustainable and Efficient Forest Management Solve High-Volume Cutting Challenges with Industrial Multi-Blade Sawing Machines

Solve High-Volume Cutting Challenges with Industrial Multi-Blade Sawing Machines How Does The Multi-Blade Saw Blade Machine Revolutionize Wood Processing

How Does The Multi-Blade Saw Blade Machine Revolutionize Wood Processing High-efficiency Automated Wood Cutting Machines - multi-blade Sawing Machines

High-efficiency Automated Wood Cutting Machines - multi-blade Sawing Machines

Contact Us

Yucheng Runming Machinery Co., Ltd.