Welcome!

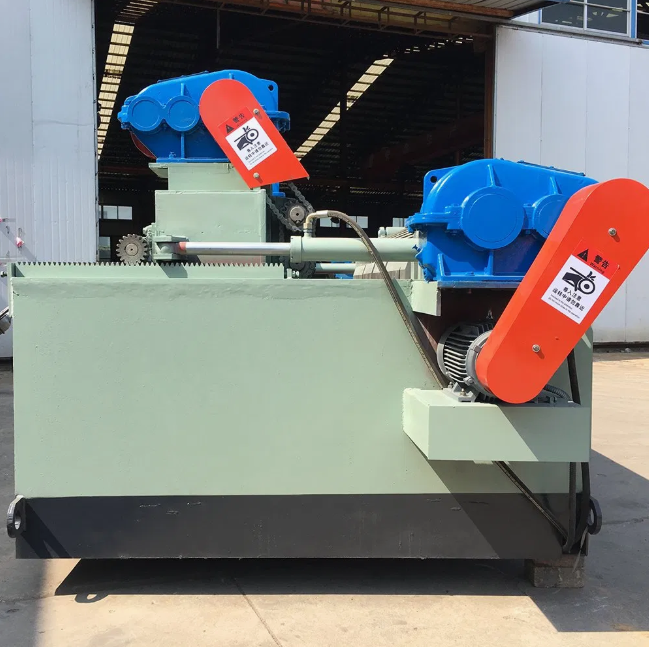

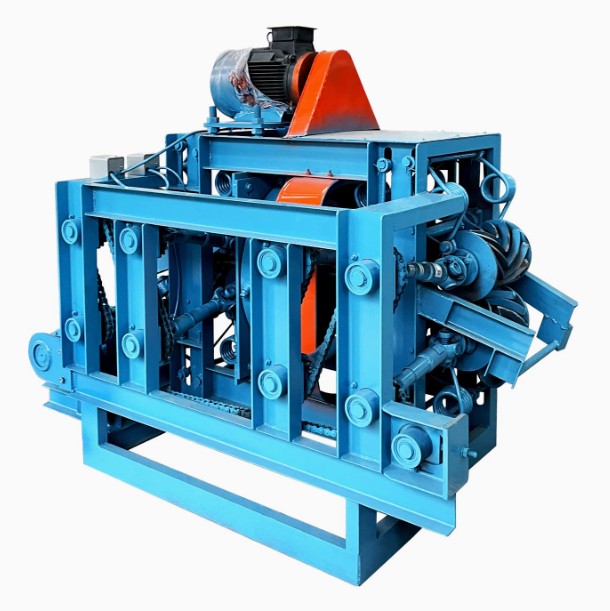

Wood Peeler: Advanced Rotary Veneer Processing System

Basic Info

| Automatic | Semi-Automatic | Certification | CE, ISO | Condition | New |

|---|---|---|---|---|---|

| Core Components | Engine, Motor, Gear | Marketing Type | Hot Product 2023 | Model NO. | BPJ11-320-6 |

| Origin | China | Package Gross Weight | 1150.000kg | Package Size | 190.00cm * 135.00cm * 170.00cm |

| Production Capacity | 50 Sets/Per Month | Showroom Location | None | Specification | 1900*1350*1700 mm |

| Transport Package | Plastic Film | Type | Peeling Machine | Warranty of Core Components | 1 Year |

| Weight (Kg) | 800 | ||||

Product Description

Product Overview

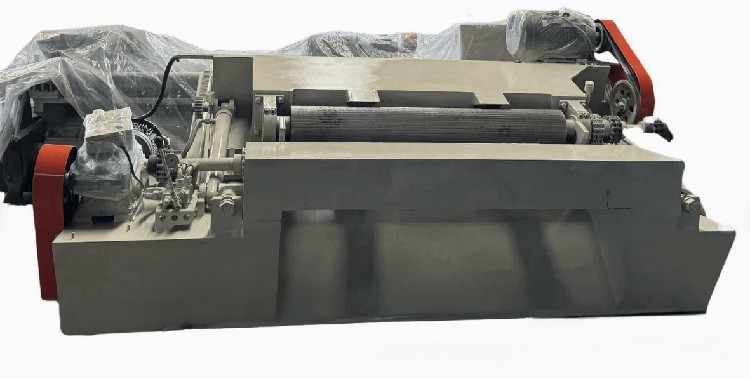

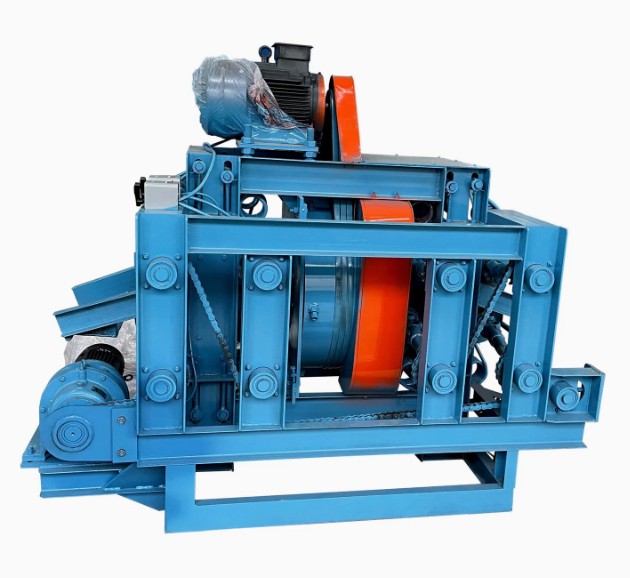

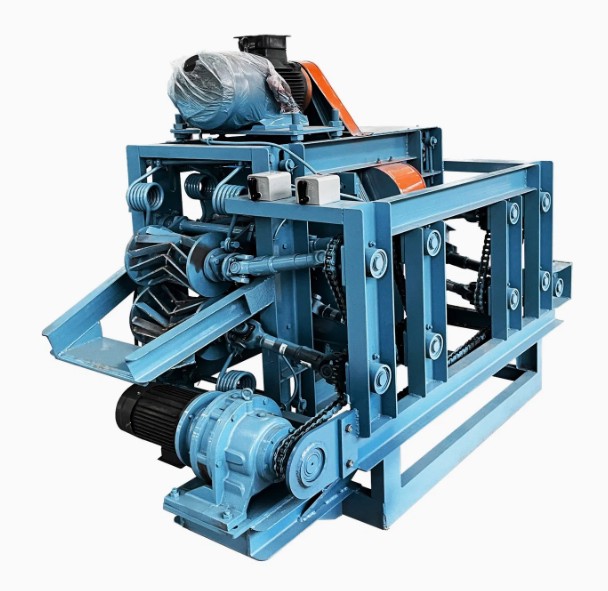

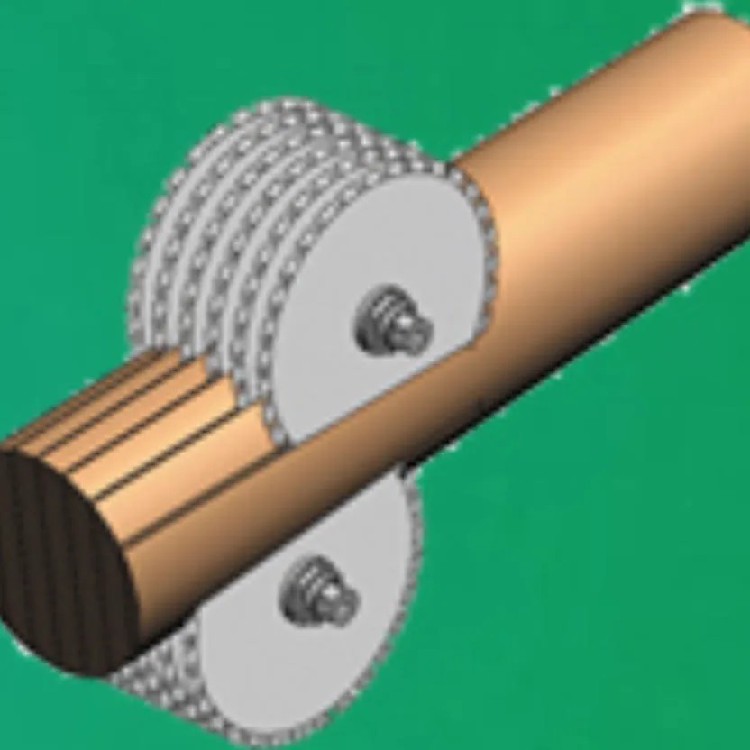

A wood peeler is a sophisticated industrial machine engineered for the high-volume production of wood veneer – thin and continuous sheets, essential for manufacturing plywood, laminated products, furniture, and decorative surfaces. Functioning as a rotary lathe, it transforms whole and debarked logs into uniform veneer ribbons through a continuous peeling process.

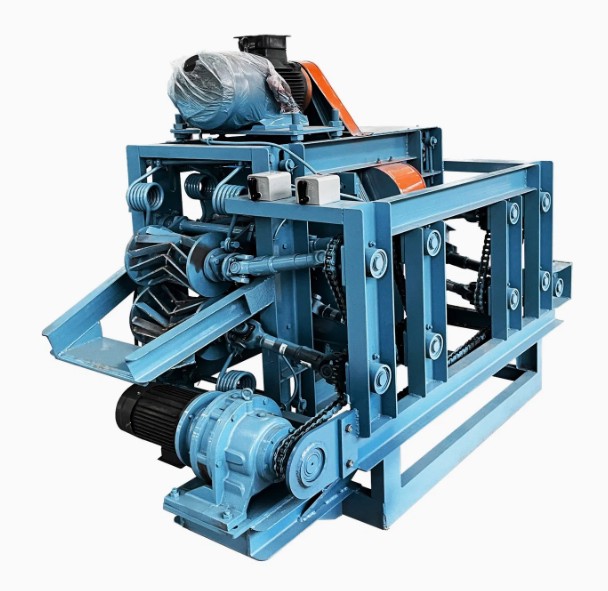

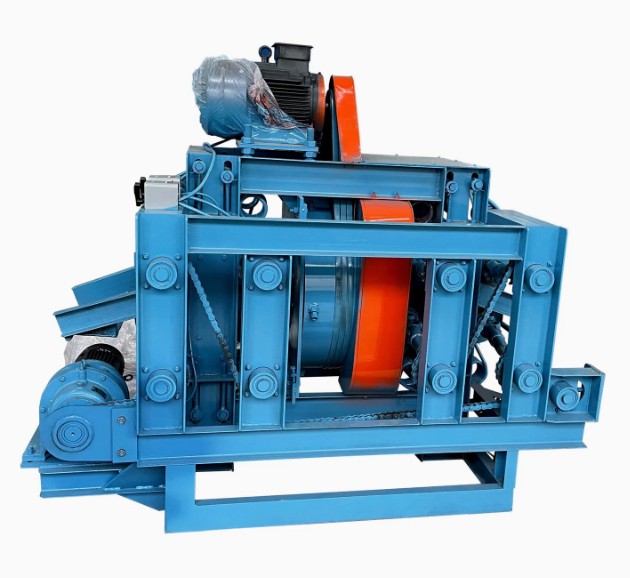

The machine horizontally secures the log between powerful spindles, rotating it at high speed. Mounted on a rigid carriage, a precisely engineered peeling knife advances steadily towards the spinning log. As the knife makes contact, it peels off a continuous sheet of veneer with controlled thickness. Modern systems incorporate sophisticated Computer Numerical Control (CNC) to meticulously manage knife positioning, pressure, feed rates, spindle speed, and log centering. Core components include a heavy-duty frame, high-torque drive system, and precision knife assembly with pressure bar, automated log handling systems, and an advanced control interface.

Key Advantages & Benefits

1. Unmatched Material Yield: Peel logs down to a small residual core diameter (typically 50-90mm), extracting the maximum usable wood fiber and dramatically reducing raw material waste compared to sawing or slicing.

2. High-Speed, Continuous Production: Enable rapid processing of logs into veneer, significantly boosting production output and operational throughput with minimal interruption.

3. Exceptional Veneer Uniformity: Advanced CNC controls ensure consistent veneer thickness and surface quality across the entire length of the ribbon, critical for downstream processing efficiency and final product integrity.

4. Broad Operational Versatility: Capable of processing a wide spectrum of log diameters, lengths, and common wood species (both hardwoods and softwoods), easily configurable for various target veneer thicknesses.

5. Enhanced Process Automation & Control: Integrated CNC systems automate critical parameters (knife pressure, feed, speed), minimizing operator dependency, ensuring repeatability, reducing errors, and enabling precise process optimization and data tracking.

6. Optimized Production Efficiency: Feature like automated log loading, precision centering, and core ejection streamline operations, reduce manual labor, and maximize overall line uptime.

7. Reduced Operational Costs: High yield, minimized waste, automation, and efficient resource utilization combine to lower the cost per unit of veneer produced.

8. Improved Workplace Safety: Designed with comprehensive safety features including guarding, safety interlocks, and emergency stop systems to protect operators during high-speed processing.

9. Superior Surface Quality: Precision knife geometry combined with pressure bar technology minimizes defects like splits, tears, and roughness, producing higher grades of usable veneer.

Why Choose Us?

Yucheng Runming Machinery Co., Ltd. is an international supplier headquartered in Shanghai, China with operations spanning Beijing and Shanghai, specifically located at 9/F Block J-K West Tower Shanghai. Specializing in agricultural machinery and parts, the company actively exports products such as the AGRIBEST series corn planters (e.g., 2BYF-4 4-row units), seed tank covers, fertilizer hoses, U-bolts, and wear-resistant sleeves to global markets, particularly the Philippines. With 114+ documented transactions and consistent activity including recent shipments as of June 20, 2024, the firm demonstrates strong trade stability and supply chain efficiency, leveraging its expertise in HS-coded machinery (e.g., 84323100000) to serve clients like Adriatic Machinery Trader.

Conclusion

The wood peeler stands as a cornerstone of efficient and sustainable wood processing. It transforms raw logs into high-value and consistent veneer with unparalleled efficiency, maximizing resource utilization, ensuring product quality, and driving profitability in modern veneer and panel production facilities.

Recommended Products

Recently Viewed

Unlocking Sustainable Forest Management with Advanced Forestry Machinery

Unlocking Sustainable Forest Management with Advanced Forestry Machinery Unlocking the Power of Forestry Machinery: Essential Tools for Sustainable and Efficient Forest Management

Unlocking the Power of Forestry Machinery: Essential Tools for Sustainable and Efficient Forest Management Solve High-Volume Cutting Challenges with Industrial Multi-Blade Sawing Machines

Solve High-Volume Cutting Challenges with Industrial Multi-Blade Sawing Machines How Does The Multi-Blade Saw Blade Machine Revolutionize Wood Processing

How Does The Multi-Blade Saw Blade Machine Revolutionize Wood Processing High-efficiency Automated Wood Cutting Machines - multi-blade Sawing Machines

High-efficiency Automated Wood Cutting Machines - multi-blade Sawing Machines

Contact Us

Yucheng Runming Machinery Co., Ltd.