Welcome!

Wood Peeler: The Core of Efficient, High-Quality Veneer Production

Basic Info

| Capacity | Max.25tons/Hour | Main Motor Power | 11kw X 2, 15kw X 2, 45kw, Rtc | Model NO. | DBP6000/DBP9000, SBP6000/SBP9000 |

|---|---|---|---|---|---|

| Origin | China | Peeling Rate | 98% | Processing Log Max. Diameter | 350mm |

| Processing Log Max. Length | 6meters, 9meters | Specification | Wood Debarkers | Transport Package | Luo Packing |

| Warranty | 1 Year | ||||

Product Description

Product Introduction

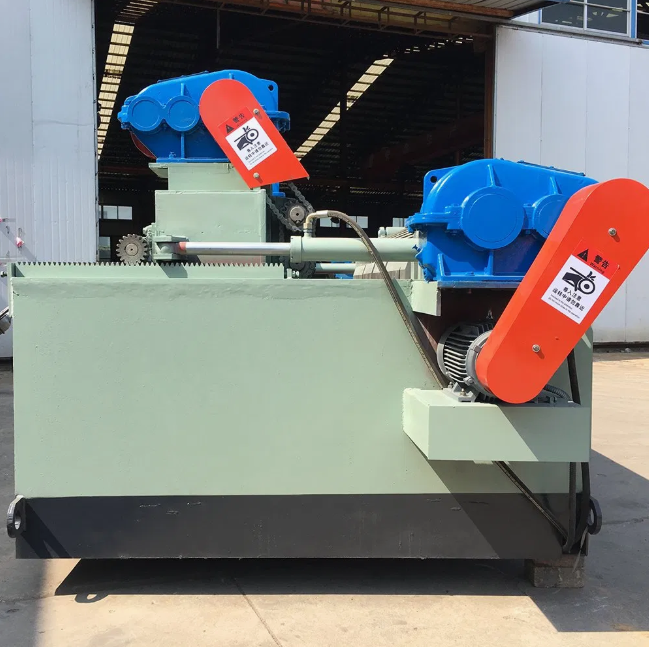

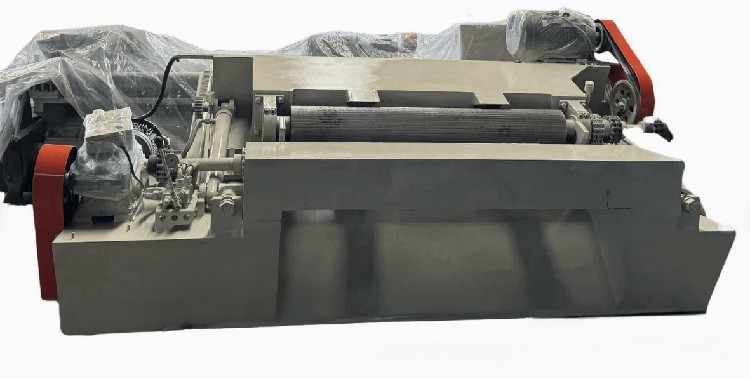

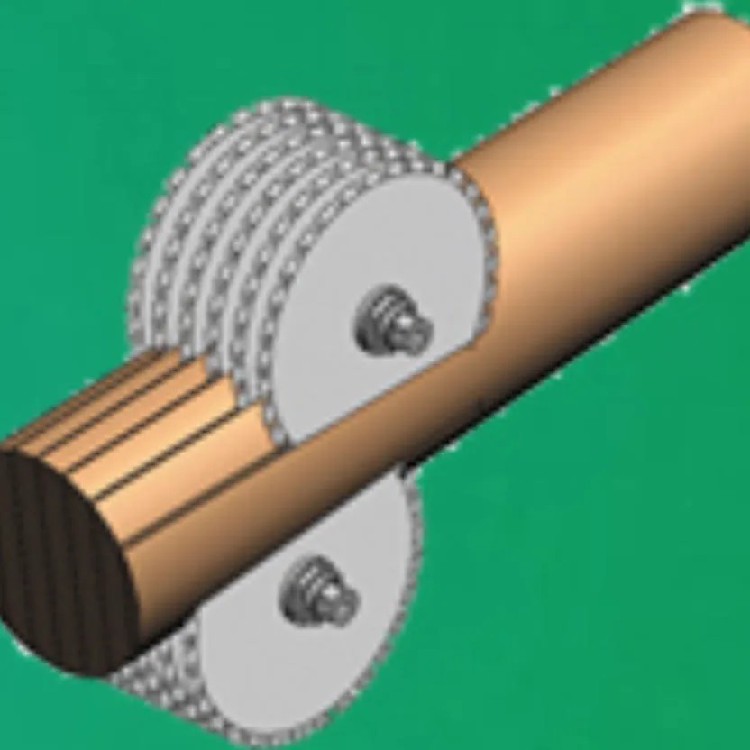

The industrial Wood Peeler stands as the fundamental machine in transforming raw timber logs into the essential building block of plywood and engineered wood products: continuous veneer sheets. This robust machine operates on the principle of rotary peeling. A prepared log (block) is securely mounted and rotated at high speed on a powerful spindle. Simultaneously, a precisely engineered peeling knife is brought into controlled contact with the rotating log. The knife peels off a thin and continuous ribbon of wood - the veneer in a smooth and helical motion. Modern wood peelers integrate sophisticated hydraulic, electronic, and digital control systems to manage critical parameters like log centering, rotation speed, knife pressure, and feed rate with exceptional accuracy. This ensures the consistent production of veneer, crucial for downstream manufacturing.

Product Advantages

1. Unmatched Production Efficiency: Engineered for high-speed operation and rapid log changeovers, significantly increasing throughput and overall plant capacity compared to older or manual methods.

2. Intelligent Processing & Optimization: Advanced control systems automatically optimize the peeling path for each individual log diameter, maximizing usable veneer yield and minimizing core waste, leading to superior raw material utilization.

3. Precision Thinning Control: Deliver exceptionally consistent veneer thickness across the entire sheet and from log to log, meeting tight tolerances required for various plywood grades and specialty applications (e.g., thin face veneers, thicker core layers).

4. Enhanced Veneer Surface Quality: Produce smooth and uniform veneer sheets with minimal lathe checks (surface fractures) and defects, reducing the need for intensive sanding later and improving the quality of the final laminated product.

5. Increased Operational Safety: Automated log handling, clamping, and knife positioning systems significantly reduce the need for operator intervention near hazardous moving parts, creating a safer workplace.

6. Reduced Labor Intensity & Costs: High levels of automation streamline the peeling process, requiring fewer operators per unit of output and lowering overall labor expenses.

7. Versatile Log Handling: Capable of processing a wide range of log diameters and lengths within design specifications, adapting to varying feedstock availability and production requirements.

8. Robust & Reliable Performance: Constructed with heavy-duty components and precision engineering to withstand the demanding forces of continuous peeling operations, ensuring high uptime, durability, and a long service life in industrial environments.

9. Improved Downstream Integration: Generate consistent and high-quality veneer ribbons that feed more efficiently and reliably into drying, clipping, sorting, and pressing lines, optimizing the entire production flow.

10. Sustainable Resource Utilization: By maximizing veneer recovery from each log and minimizing waste (cores, out-of-spec sheets), the peeler promotes efficient and responsible use of valuable timber resources.

11. Data-Driven Operation (Optional Feature): Modern variants often feature connectivity and data logging capabilities, allowing for performance monitoring, predictive maintenance, and process optimization insights.

Who We Are?

Yucheng Runming Machinery Co., Ltd. is an international supplier headquartered in Shanghai, China with operations spanning Beijing and Shanghai, specifically located at 9/F Block J-K West Tower Shanghai. Specializing in agricultural machinery and parts, the company actively exports products such as the AGRIBEST series corn planters (e.g., 2BYF-4 4-row units), seed tank covers, fertilizer hoses, U-bolts, and wear-resistant sleeves to global markets, particularly the Philippines. With 114+ documented transactions and consistent activity including recent shipments as of June 20, 2024, the firm demonstrates strong trade stability and supply chain efficiency, leveraging its expertise in HS-coded machinery (e.g., 84323100000) to serve clients like Adriatic Machinery Trader.

In Summary

The modern Wood Peeler is an indispensable investment for any veneer or plywood production facility aiming for peak efficiency, superior product quality, minimized waste, enhanced operational safety, and optimal resource utilization. It is the precision engine that reliably converts raw logs into the high-quality and consistent veneer, essential for creating durable and versatile wood-based panels and composites.

Recommended Products

Recently Viewed

Unlocking Sustainable Forest Management with Advanced Forestry Machinery

Unlocking Sustainable Forest Management with Advanced Forestry Machinery Unlocking the Power of Forestry Machinery: Essential Tools for Sustainable and Efficient Forest Management

Unlocking the Power of Forestry Machinery: Essential Tools for Sustainable and Efficient Forest Management Solve High-Volume Cutting Challenges with Industrial Multi-Blade Sawing Machines

Solve High-Volume Cutting Challenges with Industrial Multi-Blade Sawing Machines How Does The Multi-Blade Saw Blade Machine Revolutionize Wood Processing

How Does The Multi-Blade Saw Blade Machine Revolutionize Wood Processing High-efficiency Automated Wood Cutting Machines - multi-blade Sawing Machines

High-efficiency Automated Wood Cutting Machines - multi-blade Sawing Machines

Contact Us

Yucheng Runming Machinery Co., Ltd.