Welcome!

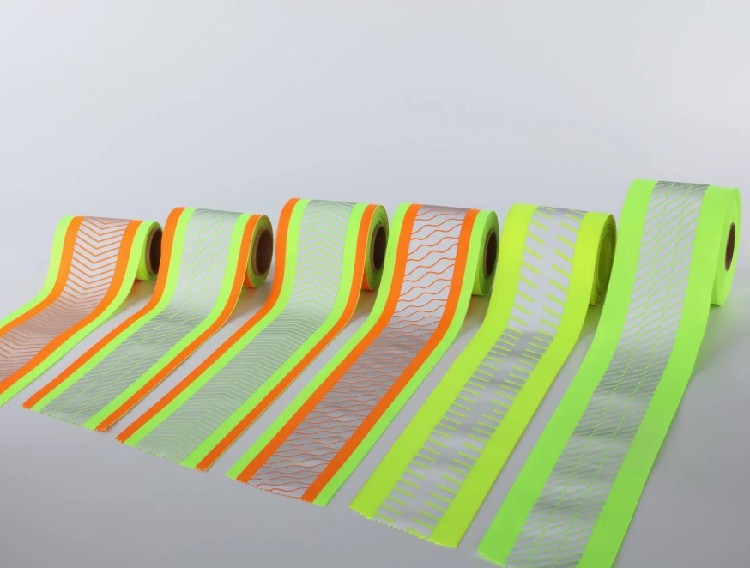

Customized Yellow and Orange PVC Marking Tape, Colored PVC Warning Tape, Waterproof Warning Tape

Basic Info

| Application | Retro-reflective Markings of Carriage | HS Code | 3919109900 | Min.Order Quantity | 180 Rolls |

|---|---|---|---|---|---|

| Packaging | 36 Rolls/CTN | Production Capacity | 100000 Rolls Per Month | Transport Package | OPP Bags, Carton, Box |

Product Description

When the sun sets and visibility plummets, standard safety measures can vanish into the darkness, leaving hazards invisible and people vulnerable. Reflective warning tape is the definitive solution to this nightly challenge. This isn't just tape; it's an active visual communication system designed to shout a warning where other signs fall silent. Engineered to capture and throw back light directly to its source, it creates a brilliant, unmissable signal in low-light and nighttime conditions. This guide illuminates the critical features, multifaceted benefits, and life-saving applications of this essential safety material.

How It Works: The Science of Retroreflection

The magic of reflective warning tape lies in its technology, not magic. It operates on the principle of retroreflection. Unlike standard reflection, which scatters light in all directions, retroreflection is designed to bounce light directly back toward its original source, such as a car's headlights or a flashlight. This is achieved through millions of microscopic glass beads or prismatic lenses embedded in the tape's surface. When light strikes these elements, it is returned with incredible efficiency, making the tape appear to glow brilliantly. The base tape is typically made from a durable, flexible vinyl or PVC material, ensuring it can withstand weather, abrasion, and temperature fluctuations while maintaining its adhesive and reflective properties.

Shining Advantages: Why Choose Reflective Tape?

The primary benefit of reflective warning tape is its unparalleled ability to enhance visibility and awareness when it is needed most. It acts as a 24/7 safety guard, passive during the day and explosively active at night. This dramatically reduces the risk of accidents, collisions, and intrusions in low-light conditions, protecting both people and assets. It provides critical reaction time for drivers, equipment operators, and pedestrians, allowing them to identify and respond to a hazard from a safe distance.

Beyond its core safety function, it is an incredibly durable and cost-effective solution. High-quality tapes are engineered to be waterproof, UV-resistant, and resistant to chemicals and solvents, ensuring the reflective performance does not degrade quickly over time. Its application is also simple and versatile. It can be adhered to almost any clean, solid surface—from metal and plastic to wood and concrete—making it a quick and affordable upgrade to existing equipment, barriers, and structures.

Lighting the Way: Diverse Applications Across Industries

The use of reflective warning tape is critical anywhere safety doesn't clock out at 5 PM. In transportation and traffic management, it is used to mark construction barriers, roadway delineators, utility vehicles, and low-overhead structures, making them visible to nighttime traffic. On airports, it outlines runways, taxiways, and critical ground support equipment.

Within warehouses, factories, and logistics centers, it is applied to the edges of loading docks, steps, low-hanging pipes, and forklift carriages to prevent trips, falls, and impacts. For emergency and first responder vehicles, it creates the highly visible chevron patterns that keep crews safe during roadside incidents. Furthermore, it is invaluable for perimeter marking of hazardous areas, safety equipment locations, and emergency exits that must be findable in a power outage or smoke-filled environment.

Selecting the Right Tape: Performance Matters

Not all reflective tapes are created equal. Performance is measured by its coefficient of retroreflection (RA), which quantifies its brilliance. Engineering-grade tape, often glass-bead-based, offers good performance for many applications. High-intensity and diamond-grade prismatic tapes provide superior brightness and wider observation angles, essential for high-speed roadways. Key selection criteria include initial reflectivity, durability against abrasion, adhesive strength for the intended surface, and expected outdoor service life before performance diminishes.

Reflective Warning Tape Q&A

Q1: How long does reflective warning tape last outdoors?

A1: The lifespan varies significantly by quality and environment. A high-quality, commercial-grade prismatic tape can maintain effective reflectivity for 5-7 years outdoors. Lower-grade tapes may degrade faster. Always check the manufacturer's specifications for rated service life.

Q2: Can it be applied to curved surfaces?

A2: Yes, many flexible conformable vinyl tapes are designed specifically to adhere to moderately curved surfaces like barrels, posts, and vehicle contours. For sharp angles, specialized tapes with stronger adhesives and more flexible backings are required.

Q3: What surfaces is it suitable for?

A3: It adheres best to clean, smooth, non-porous surfaces like metal, painted steel, rigid plastic, and glass. For porous or rough surfaces like raw concrete or weathered wood, a primer may be necessary to ensure a strong, lasting bond.

Q4: What’s the difference between fluorescent and reflective tape?

A4: Fluorescent tape (common in high-visibility clothing) absorbs UV light and re-emits it as a very bright, visible color in daytime, making it stand out against backgrounds. However, it provides no benefit in darkness. Reflective tape requires a direct light source to work but is exceptionally bright at night. They are often combined for 24-hour visibility.

Q5: How do I maintain the tape’s effectiveness?

A5: For the tape to perform optimally, its surface must be kept clean. Dirt, mud, and snow can block light from entering the reflective elements. Periodic cleaning with water and a mild detergent will restore its brilliance. Inspect it regularly for signs of peeling, cracking, or fading.

In summary, reflective warning tape is a critical, non-negotiable component of a comprehensive safety strategy for any operation that continues after dark or in low-light conditions. It is a simple, cost-effective, and powerful tool that actively works to prevent accidents and save lives by making the unseen, seen. By selecting the appropriate grade and installing it correctly, safety managers can ensure their warnings are heard loud and clear, no matter the hour.

Recommended Products

Recently Viewed

Warning Tape: Essential Safety Solution for Every Workplace and Construction Site

Warning Tape: Essential Safety Solution for Every Workplace and Construction Site Comprehensive Guide to Warning Tape: Key Features, Benefits, and Applications

Comprehensive Guide to Warning Tape: Key Features, Benefits, and Applications Yellow and Black Reflective Plastic Warning Tapes Sold Directly by The Factory

Yellow and Black Reflective Plastic Warning Tapes Sold Directly by The Factory Customized Yellow and Orange PVC Marking Tape, Colored PVC Warning Tape, Waterproof Warning Tape

Customized Yellow and Orange PVC Marking Tape, Colored PVC Warning Tape, Waterproof Warning Tape Warning Tape: Essential Safety Tool for Every Environment

Warning Tape: Essential Safety Tool for Every Environment

Contact Us

Huizhou Senping Technology Co., Limited