Welcome!

High-quality Aluminum Alloy Profiles Are Used for Doors, Windows and Building Materials

Basic Info

| Alloy | Alloy | Alloying Ingredient | 6063 | HS Code | 7604210000 |

|---|---|---|---|---|---|

| Lead Time | 15 to 35 Days | Polished Aluminum Profile | Chemical Polishing | Shape | Square |

| Temper | T3-T8 | Transport Package | Shrinkable Film, Rolled Craft Paper, Woodencarton | ||

Product Description

In the world of modern manufacturing and design, few materials offer the blend of strength, adaptability, and efficiency found in aluminum alloy profiles. These precision-engineered components are the unsung heroes behind countless structures and products, providing a backbone that is both robust and remarkably lightweight. This guide delves deep into the essence of aluminum alloy profiles, exploring their defining characteristics, undeniable benefits, and the vast array of applications they enable. Understanding these profiles is key to innovating across industries, from the smallest electronic devices to the largest architectural marvels.

Defining the Core Characteristics

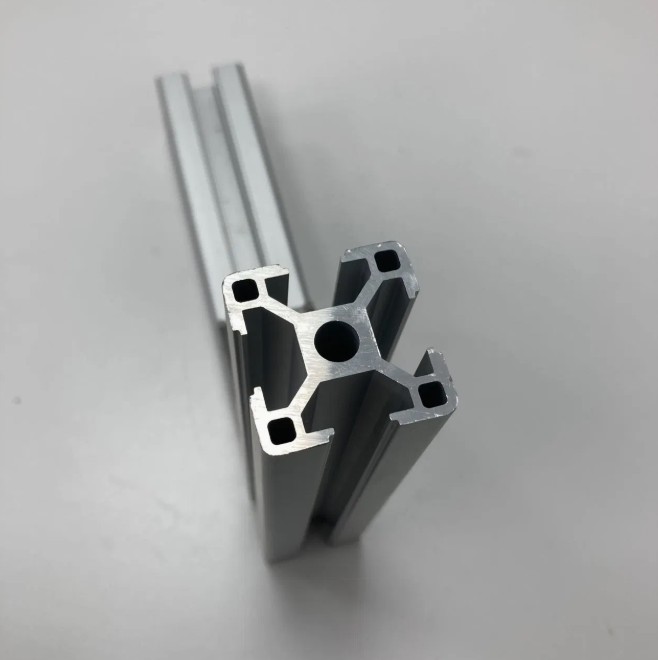

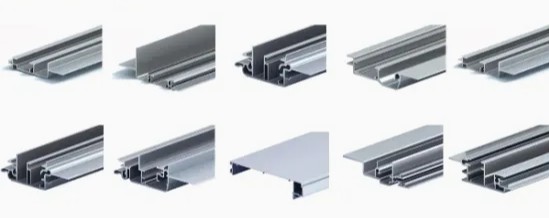

Aluminum alloy profiles are created through an extrusion process, where a heated aluminum billet is forced through a die to create a specific cross-sectional shape. This method allows for incredible design flexibility. The fundamental properties of these profiles stem from the alloying elements, such as magnesium, silicon, or zinc, which are added to pure aluminum to enhance its natural attributes.

One of the most significant characteristics is their exceptional strength-to-weight ratio. Despite being about one-third the density of steel, certain aluminum alloys can achieve strength comparable to some grades of steel, making them ideal for applications where reducing weight is critical without sacrificing structural integrity. Furthermore, aluminum naturally forms a thin, protective oxide layer when exposed to air, granting it superb corrosion resistance. This inherent property means profiles often require no additional coating, though finishes like anodizing can be applied for enhanced durability and aesthetics. Other key characteristics include excellent thermal and electrical conductivity, high reflectivity, and non-magnetic properties. Perhaps most importantly in today's eco-conscious landscape, aluminum is one hundred percent recyclable without any loss of its inherent qualities, making it a supremely sustainable material choice.

The Compelling Advantages for Modern Applications

The unique combination of characteristics translates into a powerful set of advantages for engineers, designers, and manufacturers. The lightweight nature of aluminum profiles directly contributes to energy savings, particularly in transportation industries like automotive and aerospace, where reduced weight leads to lower fuel consumption and increased payload capacity. This lightness also simplifies handling and installation during assembly, reducing labor time and costs.

The corrosion resistance of aluminum alloys ensures long-term durability and a low-maintenance lifecycle, even in harsh environments, from marine applications to industrial settings. This longevity provides excellent value over time. The versatility afforded by the extrusion process is another major advantage. It allows for the creation of highly complex, custom shapes that integrate multiple functions into a single profile, such as built-in channels for wiring or T-slots for modular assembly. This design flexibility accelerates prototyping and enables innovative solutions that would be difficult or expensive to achieve with other materials. Finally, the recyclability of aluminum supports corporate sustainability goals and contributes to a circular economy, an increasingly important factor for businesses and consumers alike.

Diverse Applications Across Industries

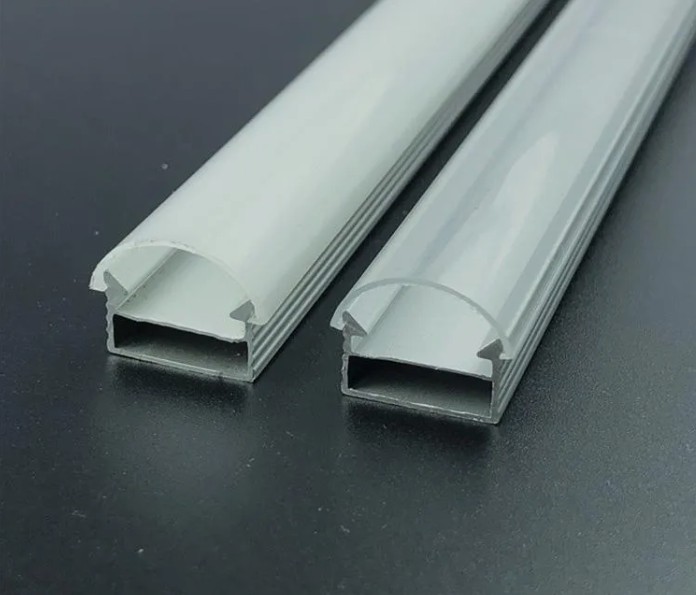

The utility of aluminum alloy profiles is virtually limitless, spanning a broad spectrum of sectors. In architecture and construction, they are ubiquitous in curtain wall systems, window frames, doors, and structural frameworks for atriums and skylights. Their strength and resistance to the elements make them perfect for these demanding applications. The transportation industry relies heavily on these profiles for vehicle frames, body panels, railcar structures, and aircraft components, where every kilogram saved is crucial.

In the industrial sector, aluminum profiles form the basis of machine guards, conveyor systems, workstations, and automated assembly lines. The modularity of systems based on T-slot profiles, for instance, allows for easy reconfiguration and adaptation. The electronics industry utilizes these profiles for heat sinks that manage thermal loads in computers and LED lighting, as well as for sturdy yet lightweight casings for sensitive equipment. Even in consumer goods, aluminum profiles are found in modern furniture, display systems, and recreational products, prized for their sleek, modern appearance and durability.

Frequently Asked Questions About Aluminum Alloy Profiles

- What is the difference between aluminum alloy profiles and pure aluminum?Pure aluminum is soft and has limited mechanical strength, making it unsuitable for most structural applications. Aluminum alloys are created by adding small percentages of other elements like magnesium, silicon, manganese, or zinc. These additions significantly enhance properties such as strength, hardness, and workability, making the resulting profiles capable of meeting demanding engineering requirements.

- How does the anodizing process benefit aluminum profiles?Anodizing is an electrochemical process that thickens the natural oxide layer on the aluminum's surface. This process greatly enhances the profile's resistance to corrosion and abrasion, making it more durable. Anodizing also allows the aluminum to be dyed in a wide range of colors, providing both protective and aesthetic benefits for architectural and design-focused applications.

- Can aluminum alloy profiles be joined or assembled easily?Yes, one of the key benefits of aluminum profiles is the ease of assembly. Many profiles are designed with features like T-slots that allow for simple bolted connections using standard connectors. They can also be joined using welding, riveting, or specialized mechanical fasteners. The best method depends on the required strength, aesthetics, and whether the assembly needs to be permanent or modular.

- Are there different grades of aluminum alloys for profiles, and how do I choose?Yes, there are numerous aluminum alloy grades, each with specific properties. Common series for extrusion include the 6xxx series (e.g., 6061 and 6063), which offer a good balance of strength, corrosion resistance, and extrudability, making them suitable for a vast range of general applications. The selection depends on factors like the required mechanical strength, need for corrosion resistance, weldability, and the complexity of the extruded shape.

- What are the environmental benefits of using aluminum profiles?Aluminum profiles offer significant environmental advantages. The primary benefit is recyclability. Aluminum can be recycled repeatedly using only a fraction of the energy required to produce primary aluminum from bauxite ore. This closed-loop recycling system reduces waste and conserves natural resources. Additionally, the long service life and low maintenance needs of aluminum products contribute to a lower overall environmental footprint.

Conclusion: A Material Shaping the Future

Aluminum alloy profiles represent a cornerstone of modern engineering and design. Their unique synergy of lightness, strength, and adaptability empowers innovation across countless fields. From creating more fuel-efficient vehicles and sustainable buildings to enabling advanced manufacturing and elegant consumer products, the potential of these profiles continues to expand. By understanding their properties and advantages, businesses and creators can make informed decisions that lead to stronger, smarter, and more efficient solutions, solidifying the role of aluminum alloy profiles as a vital material for today and tomorrow.

Recommended Products

Recently Viewed

Aluminum Profiles: Versatile, Durable, and Efficient Solutions for Every Industry

Aluminum Profiles: Versatile, Durable, and Efficient Solutions for Every Industry Aluminum Profiles: Versatile, Durable, and Cost-Effective Solutions for Various Applications

Aluminum Profiles: Versatile, Durable, and Cost-Effective Solutions for Various Applications High-quality Aluminum Alloy Profiles Are Used for Doors, Windows and Building Materials

High-quality Aluminum Alloy Profiles Are Used for Doors, Windows and Building Materials High-Quality Aluminum Alloy for Industrial Doors and Windows Can be Customized in Size

High-Quality Aluminum Alloy for Industrial Doors and Windows Can be Customized in Size Unlocking the Potential of Aluminum Profiles: Versatile, Durable, and Sustainable Solutions

Unlocking the Potential of Aluminum Profiles: Versatile, Durable, and Sustainable Solutions

Contact Us

Foshan Xinwei Aluminum Co., Ltd