Welcome!

Bicycle Disc Brakes: The Ultimate Guide to Unmatched Stopping Power

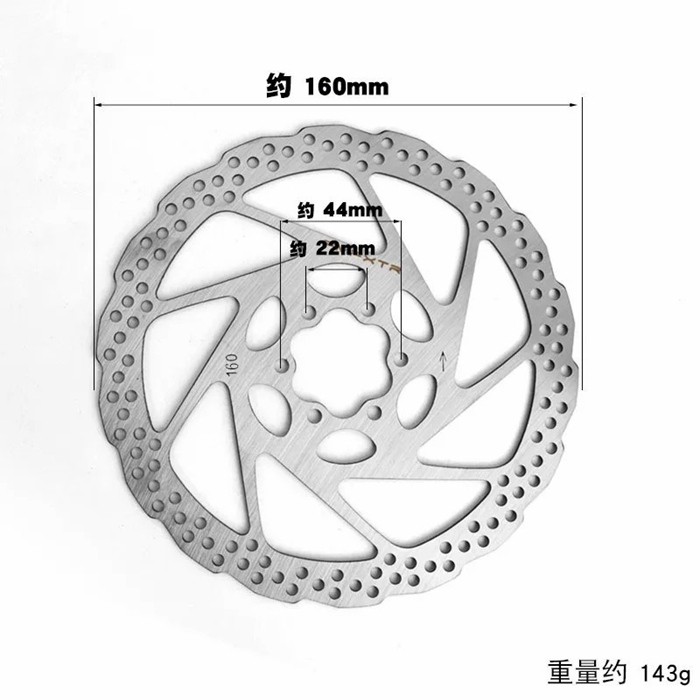

Basic Info

| Application | Kids Bike, Road Bike, Mountain Bike, Ordinary Bicycle | Brake Mode | Hydraulic | Customized | Customized |

|---|---|---|---|---|---|

| HS Code | 871494 | Material | Steel | Origin | China |

| Supplier | OEM Factory | Transport Package | Carton | Transportation | by Sea |

| Type | Brake Disc | ||||

Product Description

For modern cyclists, few innovations have made as dramatic an impact on safety and performance as disc brakes. Moving the braking surface away from the rim to a dedicated rotor at the wheel's hub, this system delivers a level of control and reliability that traditional rim brakes simply cannot match. Whether you're a mountain biker tackling steep descents, a commuter navigating rainy city streets, or a road rider seeking confidence on fast alpine passes, understanding disc brake technology is essential for choosing the right setup for your bike.

Core Characteristics of Disc Brake Systems

Disc brakes are defined by their unique operating principle and key components, which work together to provide superior stopping force.

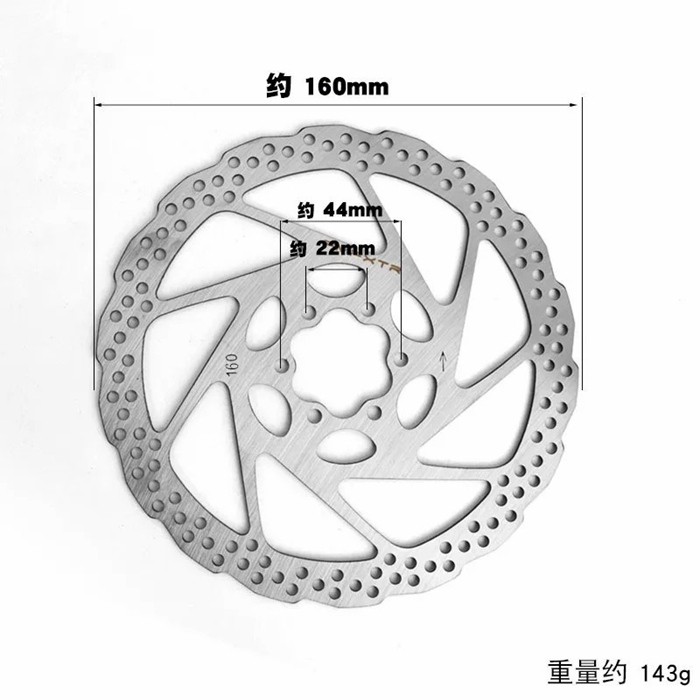

- Rotor-Centered Design: Braking power is generated when brake pads, housed within a caliper, are clamped onto a stainless steel rotor (or disc) attached to the wheel hub. This provides a consistent, powerful, and direct braking surface.

- Two Actuation Methods: Hydraulic vs. Mechanical:Hydraulic Disc Brakes: Utilize a sealed fluid system. Pulling the brake lever pushes fluid through a hose, which forces the pistons in the caliper to squeeze the pads. This system is self-adjusting, offers superior modulation (precise control over braking power), and requires less finger effort.Mechanical Disc Brakes: Use a traditional brake cable and housing to actuate the caliper. While generally easier to maintain and repair on the trail, they require more hand force and manual pad adjustment compared to hydraulic systems.

- Consistent Performance in All Conditions: Because the rotor is located away from dirt, water, and grime that can coat the wheel rim, disc brakes maintain nearly identical performance in wet, muddy, or dusty conditions. This all-weather consistency is a primary reason for their popularity.

- Superior Heat Dissipation: The metal rotor is designed to dissipate heat quickly and efficiently. This is critical on long descents where prolonged braking can cause rim brakes to overheat, leading to a dangerous loss of stopping power known as "brake fade."

Tangible Benefits of Upgrading to Disc Brakes

The shift to a disc brake system offers riders measurable advantages in safety, control, and overall riding enjoyment.

- Unmatched Stopping Power: Disc brakes provide significantly more forceful and immediate deceleration than rim brakes, allowing you to stop in a shorter distance.

- Enhanced Control and Modulation: The ability to finely meter braking force prevents wheel lock-up and skidding. This allows for smoother cornering and more controlled technical handling, especially on unpredictable terrain.

- All-Weather Reliability: Ride with confidence, knowing that a sudden rain shower or a patch of mud will not compromise your ability to stop safely. This reliability is a game-changer for commuters and adventure cyclists.

- Compatibility with Wider Tires: By eliminating the need for brake arms near the rim, disc brakes free up space for wider tires and fenders, a key trend in modern gravel and adventure bikes.

- Longer Wheel Rim Life: Since the braking force is not applied to the rim itself, your wheel rims are not worn down over time by brake pads, preserving their structural integrity and longevity.

Ideal Applications for Disc Brakes

While beneficial for nearly all cycling disciplines, disc brakes are particularly advantageous in specific scenarios.

- Mountain Biking: An absolute necessity. The powerful, consistent, and mud-shedding performance of hydraulic disc brakes is critical for managing steep, technical descents.

- Gravel and Adventure Riding: These bikes often encounter variable surfaces and conditions. Disc brakes provide the reliable stopping power needed for unpredictable terrain, from loose gravel to wet pavement.

- Road Cycling: Disc brakes have become the new standard, offering superior control on fast descents, especially in wet weather, and enabling the use of aerodynamic carbon fiber rims without wear concerns.

- Commuting and Touring: For riders who depend on their bikes in all weather conditions and often carry extra weight, the dependable stopping power of disc brakes is a fundamental safety feature.

Frequently Asked Questions About Disc Brakes

1. Are hydraulic or mechanical disc brakes better for a beginner?

Hydraulic brakes generally offer better performance with less maintenance (as they are self-adjusting). However, mechanical disc brakes can be a good entry-point option due to their lower initial cost and simpler trail-side repairs using standard cable tools. For most riders seeking the best experience, hydraulic is the recommended choice.

2. Why are my disc brakes making a squealing or grinding noise?

Squealing is often caused by contamination. Oil from your fingers or chain lube on the rotor or pads can cause this. A thorough clean with isopropyl alcohol usually solves the issue. A persistent grinding noise, however, may indicate that the brake pads are completely worn out and metal is contacting the rotor, which requires immediate replacement.

3. My brake lever feels soft. What does this mean and how can I fix it?

A soft or spongy lever is most common in hydraulic systems and typically indicates air has entered the sealed system. This requires a process called "bleeding" to remove the air bubbles and restore a firm lever feel. For mechanical brakes, a soft lever is often due to cable stretch and can be fixed by tightening the cable via the barrel adjuster.

4. Can I convert my rim brake bike to disc brakes?

This is almost always not feasible. A conversion requires a frame and fork with specific mounting points (IS or Post Mount), as well as new wheels built with hubs designed for rotor attachment. The cost and complexity involved make purchasing a new bike designed for disc brakes a more practical solution.

5. How do I know when to replace my disc brake pads?

Most disc brake pads have a wear indicator, which is a small groove in the middle of the pad material. When this groove is no longer visible, the pads should be replaced. You may also hear a metallic scraping sound once the pad material is completely worn down and the metal backing plate contacts the rotor.

Elevate Your Ride with Confident Stopping

Disc brakes represent a significant leap forward in cycling technology, offering a blend of power, control, and reliability that builds rider confidence in every situation. By choosing a bike equipped with a quality disc brake system, you are not just buying a component—you are investing in your safety and unlocking a more consistent, enjoyable, and capable riding experience.

Explore our selection of hydraulic and mechanical disc brake systems, replacement rotors, and maintenance kits to find the perfect setup for your cycling needs.

Recommended Products

Recently Viewed

Enhance Your Ride's Safety and Performance with Premium Bicycle Brakes

Enhance Your Ride's Safety and Performance with Premium Bicycle Brakes The Ultimate Guide to Bicycle Brakes: Ensuring Safety and Performance on Every Ride

The Ultimate Guide to Bicycle Brakes: Ensuring Safety and Performance on Every Ride Bicycle Disc Brakes: The Ultimate Guide to Unmatched Stopping Power

Bicycle Disc Brakes: The Ultimate Guide to Unmatched Stopping Power Your Guide to Bicycle Brakes: Safety, Performance, and Choosing the Right System

Your Guide to Bicycle Brakes: Safety, Performance, and Choosing the Right System Mastering Control and Safety: A Comprehensive Guide to Bicycle Brakes

Mastering Control and Safety: A Comprehensive Guide to Bicycle Brakes

Contact Us

FOCAN ELECTRONIC FACTORY