Welcome!

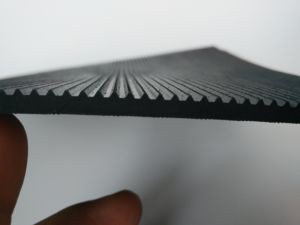

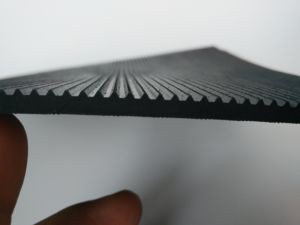

Customized Oil Fuel Resistance Hydrogenated Nitrile HNBR Rubber

Product Description

NBR has excellent oil resistance. In typical NBR structure, trans-formation accounts for about 78%. Because the molecular chain structure of NBR contains cyano, its oil resistance (such as resistance to mineral oil, liquid fuel, animal and vegetable oil and solvent) is better than that of natural rubber, neoprene and styrene-butadiene rubber. Compared with other rubbers, NBR has a wider range of service temperature, and its long-term service temperature is 120 ℃. At the same time, NBR has good low temperature resistance, with a minimum glass transition temperature of - 55 ℃. [1]

NBR has good chemical stability and good processing performance. With the increase of acrylonitrile content in its structure, its relative density increases, the curing rate increases, and the tensile strength increases, but the resilience decreases, and the cold resistance becomes poor. Because the cyano group in NBR is easy to polarize in the electric field, the dielectric property of NBR is reduced, which is semiconductor rubber. NBR can be divided into five categories according to the ACN content: ultra-high, high, medium-high, medium-low acrylonitrile. There are two production methods: continuous polymerization and batch polymerization. The continuous polymerization method is usually used for small variety and large yield production with low consumption. The batch polymerization method is applicable to multiple varieties and small batch production, and the engineering construction consumption is high. [1]

Although nitrile rubber has excellent physical and mechanical properties and processing properties, it is not as good as fluororubber and acrylate rubber in acid gasoline and high temperature (150 ℃) environment for a long time. Therefore, hydrogenated nitrile rubber (HNBR) with excellent performance has been developed. In addition, nitrile rubber and carboxyl nitrile rubber (XNBR) with extremely cold resistance and high purity have also been developed.

Nitrile rubber is a light brown elastomer with a molecular weight of about 700000. Due to its strong polar CN group, it has excellent stability for aliphatic hydrocarbon oils and gasoline. With the increase of ACN content, the polarity of NBR increases, the chain flexibility decreases, the interaction between chains increases, the content of double bonds in the molecular chain decreases, and the degree of saturation increases, which also results in a series of performance changes. Its oil resistance, air tightness and wear resistance increase, while its processing and cold resistance decrease.

Recommended Products

Recently Viewed

Water Resistant Oil Fuel Resistance Hydrogenated Nitrile HNBR Rubber

Water Resistant Oil Fuel Resistance Hydrogenated Nitrile HNBR Rubber Water Resistant Nature Neoprene EPDM Silicone Nitrile Viton Rubber Sheet for Gaskets

Water Resistant Nature Neoprene EPDM Silicone Nitrile Viton Rubber Sheet for Gaskets Water Resistant EPDM SBR Neoprene Nitrile Silicone Natural Anti Slip Rubber Sheet

Water Resistant EPDM SBR Neoprene Nitrile Silicone Natural Anti Slip Rubber Sheet High Quality Oil Fuel Resistance Hydrogenated Nitrile HNBR Rubber

High Quality Oil Fuel Resistance Hydrogenated Nitrile HNBR Rubber Customized EPDM SBR Neoprene Nitrile Silicone Natural Anti Slip Rubber Sheet

Customized EPDM SBR Neoprene Nitrile Silicone Natural Anti Slip Rubber Sheet

Contact Us

Nanjing Demeters Rubber & Plastic Products Co., Ltd.