Welcome!

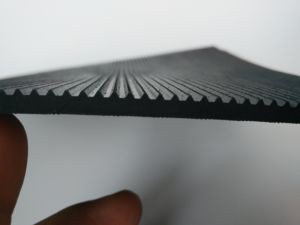

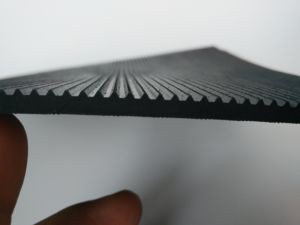

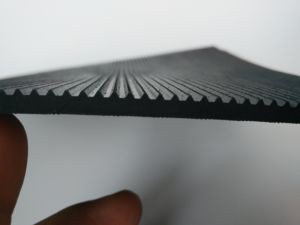

Factory Manufacture Nitrile FDA Liquid Silicone Rubber Spiral Wound Sheet Sealing Gasket Washer

Product Description

Nitrile rubber is a copolymer of acrylonitrile and butadiene monomer, which is mainly produced by low-temperature lotion polymerization. It has excellent oil resistance, high abrasion resistance, good heat resistance and strong adhesion. Its disadvantages are poor low temperature resistance, poor ozone resistance, poor insulation performance and slightly low elasticity.

Nitrile rubber is mainly used to manufacture oil-resistant rubber products. There are five kinds of acrylonitrile content (%) in nitrile rubber: 42 ~ 46, 36 ~ 41, 31 ~ 35, 25 ~ 30, 18 ~ 24. The higher the content of acrylonitrile, the better the oil resistance, but the lower the cold resistance. It can be used in air at 120 ℃ or oil at 150 ℃ for a long time. In addition, it also has good water resistance, air tightness and excellent bonding performance. It is widely used in making various oil-resistant rubber products, various oil-resistant washers, gaskets, sleeves, flexible packaging, flexible rubber tubes, printing and dyeing rubber rolls, cable rubber materials, etc., and has become an indispensable elastic material in the automobile, aviation, oil, copy and other industries.

NBR has excellent oil resistance. In typical NBR structure, trans-formation accounts for about 78%. Because the molecular chain structure of NBR contains cyano, its oil resistance (such as resistance to mineral oil, liquid fuel, animal and vegetable oil and solvent) is better than that of natural rubber, neoprene and styrene-butadiene rubber. Compared with other rubbers, NBR has a wider range of service temperature, and its long-term service temperature is 120 ℃. At the same time, NBR has good low temperature resistance, with a minimum glass transition temperature of - 55 ℃. [1]

NBR has good chemical stability and good processing performance. With the increase of acrylonitrile content in its structure, its relative density increases, the curing rate increases, and the tensile strength increases, but the resilience decreases, and the cold resistance becomes poor. Because the cyano group in NBR is easy to polarize in the electric field, the dielectric property of NBR is reduced, which is semiconductor rubber. NBR can be divided into five categories according to the ACN content: ultra-high, high, medium-high, medium-low acrylonitrile. There are two production methods: continuous polymerization and batch polymerization. The continuous polymerization method is usually used for small variety and large yield production with low consumption. The batch polymerization method is applicable to multiple varieties and small batch production, and the engineering construction consumption is high. [1]

Recommended Products

Recently Viewed

Water Resistant Oil Fuel Resistance Hydrogenated Nitrile HNBR Rubber

Water Resistant Oil Fuel Resistance Hydrogenated Nitrile HNBR Rubber Water Resistant Nature Neoprene EPDM Silicone Nitrile Viton Rubber Sheet for Gaskets

Water Resistant Nature Neoprene EPDM Silicone Nitrile Viton Rubber Sheet for Gaskets Water Resistant EPDM SBR Neoprene Nitrile Silicone Natural Anti Slip Rubber Sheet

Water Resistant EPDM SBR Neoprene Nitrile Silicone Natural Anti Slip Rubber Sheet High Quality Oil Fuel Resistance Hydrogenated Nitrile HNBR Rubber

High Quality Oil Fuel Resistance Hydrogenated Nitrile HNBR Rubber Customized EPDM SBR Neoprene Nitrile Silicone Natural Anti Slip Rubber Sheet

Customized EPDM SBR Neoprene Nitrile Silicone Natural Anti Slip Rubber Sheet

Contact Us

Nanjing Demeters Rubber & Plastic Products Co., Ltd.