Welcome!

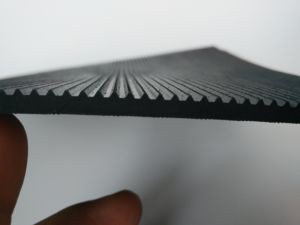

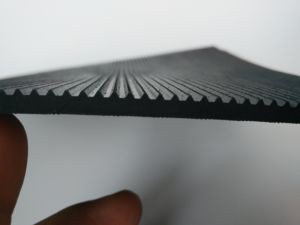

Low Price Nitrile FDA Liquid Silicone Rubber Spiral Wound Sheet Sealing Gasket Washer

Product Description

Nitrile rubber is mainly used to manufacture oil-resistant rubber products. There are five kinds of acrylonitrile content (%) in nitrile rubber: 42 ~ 46, 36 ~ 41, 31 ~ 35, 25 ~ 30, 18 ~ 24. The higher the content of acrylonitrile, the better the oil resistance, but the lower the cold resistance. It can be used in air at 120 ℃ or oil at 150 ℃ for a long time. In addition, it also has good water resistance, air tightness and excellent bonding performance. It is widely used in making various oil-resistant rubber products, various oil-resistant washers, gaskets, sleeves, flexible packaging, flexible rubber tubes, printing and dyeing rubber rolls, cable rubber materials, etc., and has become an indispensable elastic material in the automobile, aviation, oil, copy and other industries.

Nitrile rubber is a light brown elastomer with a molecular weight of about 700000. Due to its strong polar CN group, it has excellent stability for aliphatic hydrocarbon oils and gasoline. With the increase of ACN content, the polarity of NBR increases, the chain flexibility decreases, the interaction between chains increases, the content of double bonds in the molecular chain decreases, and the degree of saturation increases, which also results in a series of performance changes. Its oil resistance, air tightness and wear resistance increase, while its processing and cold resistance decrease.

Recommended Products

Recently Viewed

Water Resistant Oil Fuel Resistance Hydrogenated Nitrile HNBR Rubber

Water Resistant Oil Fuel Resistance Hydrogenated Nitrile HNBR Rubber Water Resistant Nature Neoprene EPDM Silicone Nitrile Viton Rubber Sheet for Gaskets

Water Resistant Nature Neoprene EPDM Silicone Nitrile Viton Rubber Sheet for Gaskets Water Resistant EPDM SBR Neoprene Nitrile Silicone Natural Anti Slip Rubber Sheet

Water Resistant EPDM SBR Neoprene Nitrile Silicone Natural Anti Slip Rubber Sheet High Quality Oil Fuel Resistance Hydrogenated Nitrile HNBR Rubber

High Quality Oil Fuel Resistance Hydrogenated Nitrile HNBR Rubber Customized EPDM SBR Neoprene Nitrile Silicone Natural Anti Slip Rubber Sheet

Customized EPDM SBR Neoprene Nitrile Silicone Natural Anti Slip Rubber Sheet

Contact Us

Nanjing Demeters Rubber & Plastic Products Co., Ltd.