Welcome!

Small Rubber Floor Mat Product Hydraulic Vulcanizing Press Making Machinery

Product Description

If the working environment is humid and watery, when disassembling and transporting the vulcanizing machine, it is necessary to pad the ground with objects, and do not allow the vulcanizing machine to come into direct contact with water; If water enters the heating plate due to improper operation during use, first contact the manufacturer for maintenance. If emergency repair is necessary, open the upper cover plate of the heating plate, pour out the water first, and then set the electric control box to manual operation. Heat it to 100 ℃, maintain a constant temperature for half an hour, dry the line, and conduct belt bonding in manual mode. At the same time, the manufacturer should be contacted in a timely manner to replace the entire circuit.

In the rubber industry, the column type flat belt vulcanizer is an earlier type of machine. In the past, the flat belt vulcanizer used in China was mostly of column type structure, but currently, it is mostly of frame type structure. The lateral stiffness of a single frame plate of a frame type flat belt vulcanizer is worse than that of a column. However, since the frame of the frame type flat belt vulcanizer is composed of multiple frame plates, the entire machine has sufficient lateral stiffness

Recommended Products

Recently Viewed

Automatic Plastic Shredder Granulator Pet Bottle Film Recycling Line Packing Plastic Film with FDA Certificate

Automatic Plastic Shredder Granulator Pet Bottle Film Recycling Line Packing Plastic Film with FDA Certificate PE Plastic Granulator Granulator Granulation Line Pelletizer Recycling Plant Pelletizing Extruder Extrusion Machine with FDA Certificate

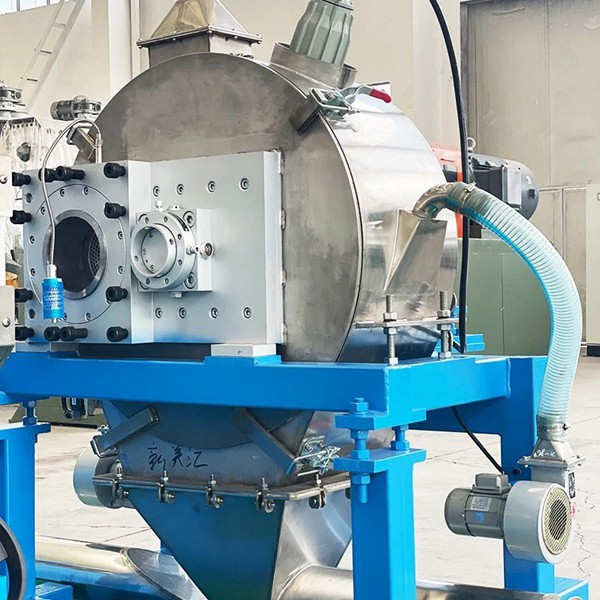

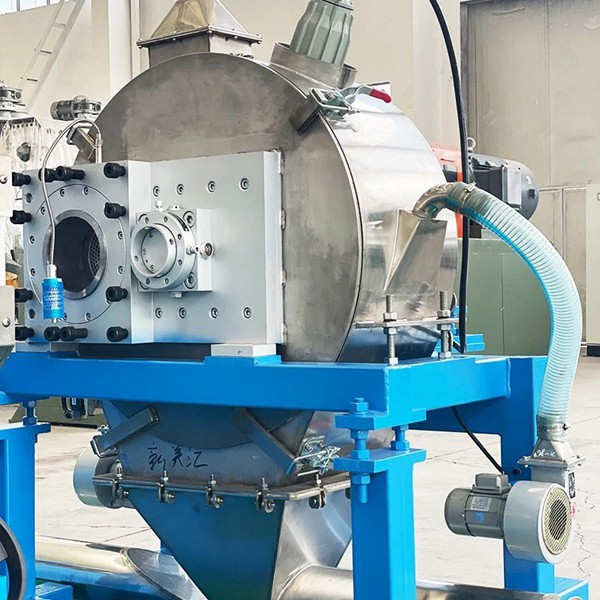

PE Plastic Granulator Granulator Granulation Line Pelletizer Recycling Plant Pelletizing Extruder Extrusion Machine with FDA Certificate Factory Hot Sales Granulator Granulation Line Pelletizer Recycling Plant Pelletizing Extruder Extrusion Machine with Hydraulic Filter/Plastic Pellet Machine

Factory Hot Sales Granulator Granulation Line Pelletizer Recycling Plant Pelletizing Extruder Extrusion Machine with Hydraulic Filter/Plastic Pellet Machine Factory Hot Sales Granulator Granulation Line Pelletizer Recycling Plant Pelletizing Extruder Extrusion Machine with Hydraulic Filter/Plastic Pellet Machine

Factory Hot Sales Granulator Granulation Line Pelletizer Recycling Plant Pelletizing Extruder Extrusion Machine with Hydraulic Filter/Plastic Pellet Machine Factory Hot Sales Plastic Granulator with Hydraulic Filter/Plastic Pellet Machine with FDA Certificate

Factory Hot Sales Plastic Granulator with Hydraulic Filter/Plastic Pellet Machine with FDA Certificate

Contact Us

Fuzhou Smartell Technology Co., Ltd.