Welcome!

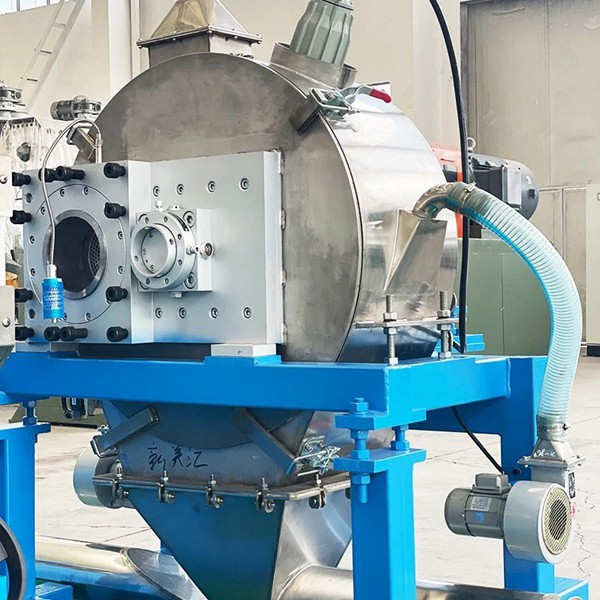

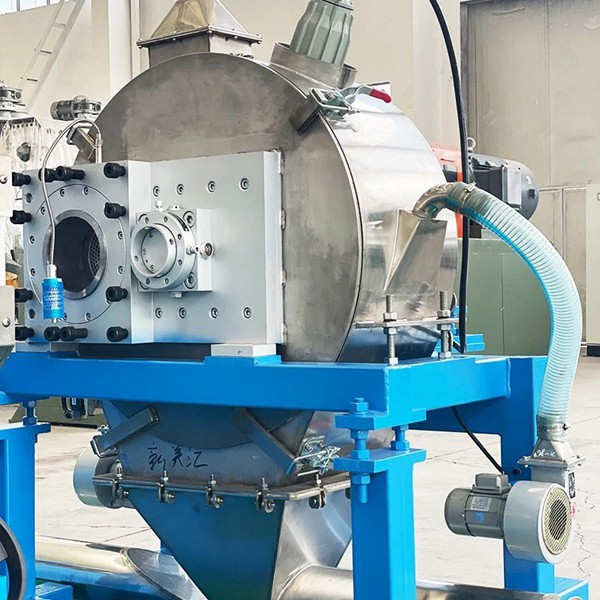

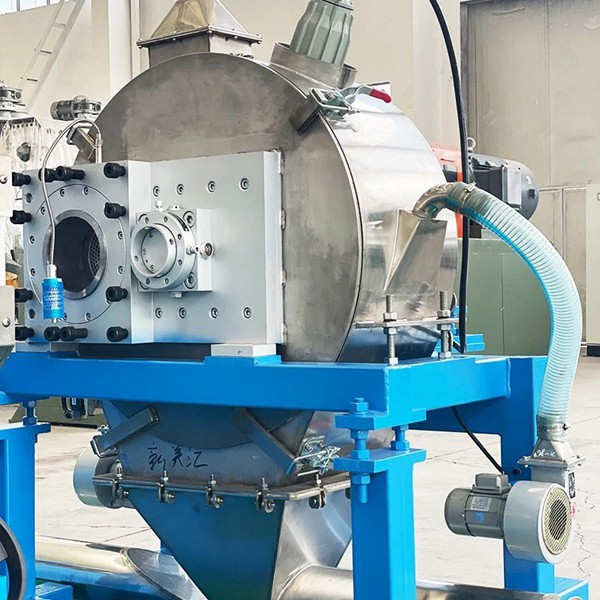

Factory Hot Sales Granulator Granulation Line Pelletizer Recycling Plant Pelletizing Extruder Extrusion Machine with Hydraulic Filter/Plastic Pellet Machine

Product Description

Plastic pellet machines have multiple advantages. Firstly, it can convert discarded plastic into reusable resources, effectively solving the environmental problems caused by plastic waste; Secondly, the plastic pellet machine has high production efficiency and can process a large amount of waste plastic in a short period of time; In addition, it also has the characteristics of easy operation and maintenance, making the plastic recycling process more efficient and economical.

The working principle of a plastic pellet machine is mainly based on physical methods, which usually includes the following steps: first, waste plastic is sent to the machine for crushing treatment, breaking it into smaller pieces; Next, these fragments are cleaned to remove impurities; Then, the cleaned fragments are sent to the heating area for melting; Finally, the melted plastic is cut into uniformly sized plastic particles through molds and cutting devices.

The plastic pellet machine adopts advanced heating and cooling systems, which can quickly heat waste plastic to a molten state and achieve rapid cooling, greatly improving production efficiency. Meanwhile, the equipment adopts energy-saving design, effectively reducing energy consumption. The plastic pellet machine is manufactured using high-quality materials and precise processing technology to ensure stable and reliable operation of the equipment. In addition, the equipment also has multiple safety protection measures such as overload protection and overheating protection, effectively ensuring the safety of operators.

Plastic pellet machine is a specialized equipment that processes waste plastic into recycled plastic pellets through crushing, cleaning, melting, cutting, and other processes. Its working principle is mainly based on physical methods, which convert waste plastic into reusable plastic particles through steps such as heating, extrusion, and cutting.

Recommended Products

Recently Viewed

Automatic Plastic Shredder Granulator Pet Bottle Film Recycling Line Packing Plastic Film with FDA Certificate

Automatic Plastic Shredder Granulator Pet Bottle Film Recycling Line Packing Plastic Film with FDA Certificate PE Plastic Granulator Granulator Granulation Line Pelletizer Recycling Plant Pelletizing Extruder Extrusion Machine with FDA Certificate

PE Plastic Granulator Granulator Granulation Line Pelletizer Recycling Plant Pelletizing Extruder Extrusion Machine with FDA Certificate Factory Hot Sales Granulator Granulation Line Pelletizer Recycling Plant Pelletizing Extruder Extrusion Machine with Hydraulic Filter/Plastic Pellet Machine

Factory Hot Sales Granulator Granulation Line Pelletizer Recycling Plant Pelletizing Extruder Extrusion Machine with Hydraulic Filter/Plastic Pellet Machine Factory Hot Sales Granulator Granulation Line Pelletizer Recycling Plant Pelletizing Extruder Extrusion Machine with Hydraulic Filter/Plastic Pellet Machine

Factory Hot Sales Granulator Granulation Line Pelletizer Recycling Plant Pelletizing Extruder Extrusion Machine with Hydraulic Filter/Plastic Pellet Machine Factory Hot Sales Plastic Granulator with Hydraulic Filter/Plastic Pellet Machine with FDA Certificate

Factory Hot Sales Plastic Granulator with Hydraulic Filter/Plastic Pellet Machine with FDA Certificate

Contact Us

Qingdao Xiangjie Rubber Machinery Co., Ltd.