Welcome!

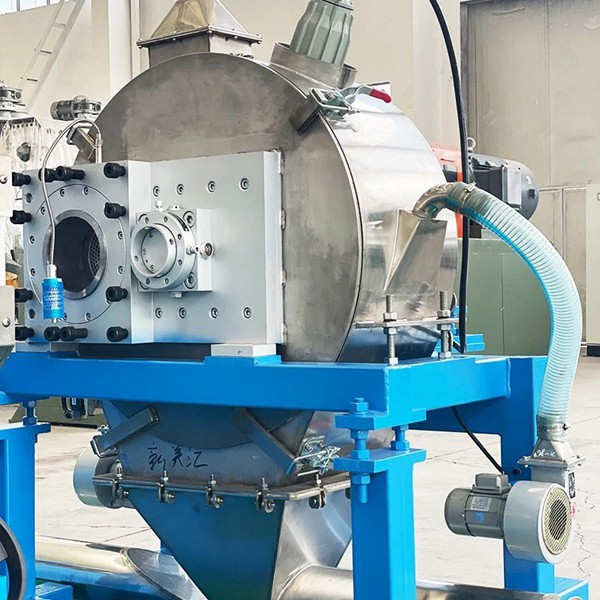

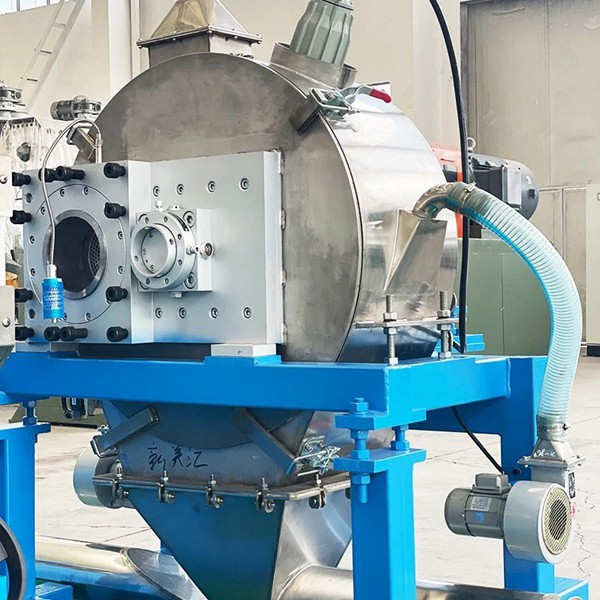

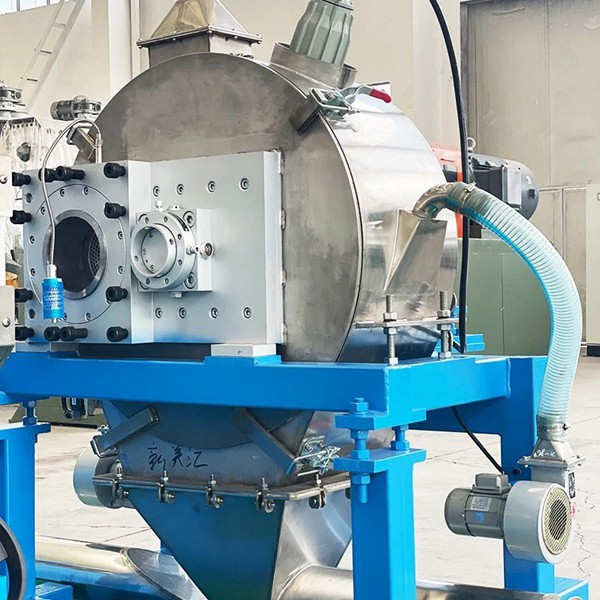

Factory Hot Sales Plastic Recycling Granulator/Plastic Film Waste Granulator/Plastic Bottle Pelleting Machine with FDA Certificate

Product Description

Plastic pellet machine is a key equipment for the recycling of waste plastics, playing an important role in promoting the development of environmental protection and realizing the resource utilization of plastic waste. With the continuous progress of technology and the improvement of environmental awareness, plastic pellet machines will be more widely used and developed in the future.

The working principle of a plastic pellet machine is mainly based on physical methods, which usually includes the following steps: first, waste plastic is sent to the machine for crushing treatment, breaking it into smaller pieces; Next, these fragments are cleaned to remove impurities; Then, the cleaned fragments are sent to the heating area for melting; Finally, the melted plastic is cut into uniformly sized plastic particles through molds and cutting devices.

A plastic pellet machine is a mechanical equipment specifically designed to convert waste plastic into recycled plastic pellets. With the continuous increase of global plastic waste and the increasing awareness of environmental protection, plastic pellet machines play a crucial role in the plastic recycling industry.

The plastic pellet machine is suitable for processing various types of waste plastics, such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), etc. By replacing different molds and blades, the equipment can produce plastic particles of different specifications and shapes to meet the diverse needs of the market. The plastic pellet machine does not produce harmful gases and wastewater during the production process, which meets environmental protection requirements. Meanwhile, the use of recycled plastic particles can reduce the demand for native plastics, reduce environmental pollution and resource waste.

Recommended Products

Recently Viewed

Automatic Plastic Shredder Granulator Pet Bottle Film Recycling Line Packing Plastic Film with FDA Certificate

Automatic Plastic Shredder Granulator Pet Bottle Film Recycling Line Packing Plastic Film with FDA Certificate PE Plastic Granulator Granulator Granulation Line Pelletizer Recycling Plant Pelletizing Extruder Extrusion Machine with FDA Certificate

PE Plastic Granulator Granulator Granulation Line Pelletizer Recycling Plant Pelletizing Extruder Extrusion Machine with FDA Certificate Factory Hot Sales Granulator Granulation Line Pelletizer Recycling Plant Pelletizing Extruder Extrusion Machine with Hydraulic Filter/Plastic Pellet Machine

Factory Hot Sales Granulator Granulation Line Pelletizer Recycling Plant Pelletizing Extruder Extrusion Machine with Hydraulic Filter/Plastic Pellet Machine Factory Hot Sales Granulator Granulation Line Pelletizer Recycling Plant Pelletizing Extruder Extrusion Machine with Hydraulic Filter/Plastic Pellet Machine

Factory Hot Sales Granulator Granulation Line Pelletizer Recycling Plant Pelletizing Extruder Extrusion Machine with Hydraulic Filter/Plastic Pellet Machine Factory Hot Sales Plastic Granulator with Hydraulic Filter/Plastic Pellet Machine with FDA Certificate

Factory Hot Sales Plastic Granulator with Hydraulic Filter/Plastic Pellet Machine with FDA Certificate

Contact Us

Qingdao Xiangjie Rubber Machinery Co., Ltd.