Welcome!

Chinese suppliers Pressure Hydraulic Press Machinery for Deep Drawn & Metal Stamping

Product Description

Stamping is a pressure processing method that uses a stamping die to apply pressure to a material on a press at room temperature to produce plastic deformation or separation to obtain the desired shape and size of the part. This processing method is commonly referred to as cold stamping. Although various types of stamping dies have different structural forms and complexity, and the components that make up the dies are diverse, they are always divided into upper and lower molds. The upper mold is generally fixed to the slider of the press through the mold handle, and moves up and down along the press guide rail together with the slider. The lower mold is fixed to the workbench of the press.

During a single stroke operation of the stamping equipment, there shall be no continuous stamping stroke. When selecting continuous stroke operation, a pre control action link should be provided during the operation process. The pressing equipment must have an emergency stop button and be self-locking. Interlock control shall be provided between foot operation and hand operation. Protective shields shall be installed for transmission gears, pulleys, flywheels, levers, and other transmission components exposed outside and on top of the fuselage.

Recommended Products

Recently Viewed

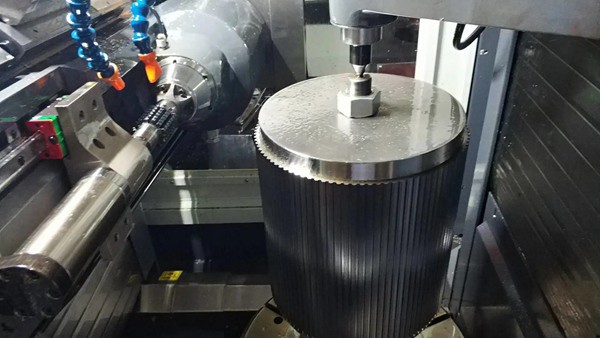

High Speed Gear Hobbing Hobber Machine for Shaft End Spline Gear Hobbing Machine

High Speed Gear Hobbing Hobber Machine for Shaft End Spline Gear Hobbing Machine China Manufacturer Gear Hobbing Shaping Grinding Honing Worm Machine for Gear Processing Cutting Hobber

China Manufacturer Gear Hobbing Shaping Grinding Honing Worm Machine for Gear Processing Cutting Hobber China Manufacturer Special Spline Hobbing Machine for Shaft End Spline Gear Hobbing Machine

China Manufacturer Special Spline Hobbing Machine for Shaft End Spline Gear Hobbing Machine Automatic CNC Special Spline Hobbing Machine for Gear Processing Cutting Hobber

Automatic CNC Special Spline Hobbing Machine for Gear Processing Cutting Hobber China Manufacturer Gear Hobbing Hobber Machine for Gear Processing Cutting Hobber

China Manufacturer Gear Hobbing Hobber Machine for Gear Processing Cutting Hobber

Contact Us

Nanjing Prima CNC Machinery Co., Ltd.