Welcome!

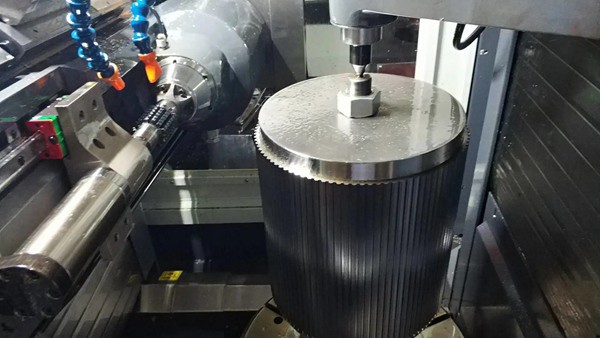

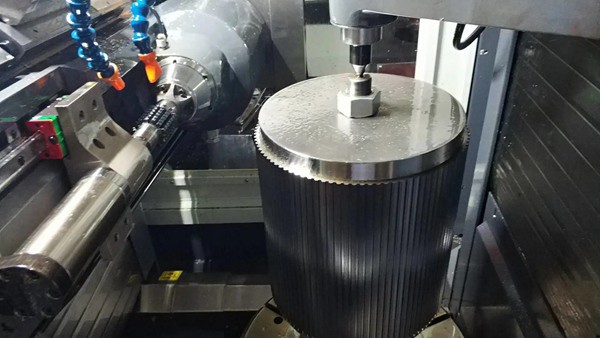

China Manufacturer Gear Hobbing Hobber Machine for Bevel Gear Cutting Milling Processing

Product Description

The hobbing machine generates less cutting heat during the machining process, and the cutting force is dispersed at multiple rolling points, which helps to reduce energy consumption and environmental pollution. Gear hobbing machines have an irreplaceable position in the field of gear processing due to their advantages of high precision, high efficiency, good surface quality, wide adaptability, easy operation, and energy conservation and environmental protection. With the continuous development and technological progress of the manufacturing industry, gear hobbing machines will continue to play an important role in the field of gear processing.

The operation process of a gear hobbing machine mainly includes steps such as machine preparation, workpiece clamping, adjusting machining parameters, and starting machining. Firstly, it is necessary to place the gear hobbing machine on a stable foundation and secure it, and install the corresponding gear hobbing tools and fixtures. Then, inspect and adjust the gear hobbing machine to ensure that all parts are working properly. Next, place the gear to be machined into the workpiece fixture and clamp it, and set the machining parameters according to the shape and machining requirements of the gear. Finally, start the gear hobbing machine and start processing. If the processing quality does not meet the requirements, adjustments and corrections should be made in a timely manner.

As an important equipment in the field of gear processing, gear hobbing machines have attracted widespread attention due to their high precision, high efficiency machining capabilities, and wide application range. With the continuous development and technological progress of the manufacturing industry, gear hobbing machines will continue to play an important role in the field of gear processing. The gear hobbing machine adopts a hobbing processing method, which has lower requirements for gear materials. Compared to other machining methods, gear hobbing machines can effectively reduce the loss and deformation of gear materials, thereby improving the service life of gears.

Gear hobbing machines have a high degree of automation and can achieve continuous and high-speed machining of gears. Compared to traditional cutting methods, gear hobbing machines have higher production efficiency, which helps to reduce production costs. The gear hobbing machine adopts rolling cutting method, which generates less cutting heat, so it will not produce heat treatment effects such as quenching and annealing on the gear surface. This can ensure the surface quality of the gears and prevent the occurrence of cracks and fatigue.

Gear hobbing machines can be divided into two types according to layout: vertical and horizontal. Large and medium-sized gear hobbing machines are mostly vertical, while small gear hobbing machines and gear hobbing machines specifically designed for processing long shaft gears are both horizontal. Vertical gear hobbing machines are divided into two types: worktable movement and column movement. In practical applications, choose the appropriate type of gear hobbing machine based on processing requirements and workpiece characteristics.

Recommended Products

Recently Viewed

High Speed Gear Hobbing Hobber Machine for Shaft End Spline Gear Hobbing Machine

High Speed Gear Hobbing Hobber Machine for Shaft End Spline Gear Hobbing Machine China Manufacturer Gear Hobbing Shaping Grinding Honing Worm Machine for Gear Processing Cutting Hobber

China Manufacturer Gear Hobbing Shaping Grinding Honing Worm Machine for Gear Processing Cutting Hobber China Manufacturer Special Spline Hobbing Machine for Shaft End Spline Gear Hobbing Machine

China Manufacturer Special Spline Hobbing Machine for Shaft End Spline Gear Hobbing Machine Automatic CNC Special Spline Hobbing Machine for Gear Processing Cutting Hobber

Automatic CNC Special Spline Hobbing Machine for Gear Processing Cutting Hobber China Manufacturer Gear Hobbing Hobber Machine for Gear Processing Cutting Hobber

China Manufacturer Gear Hobbing Hobber Machine for Gear Processing Cutting Hobber

Contact Us

Shandong Raytu Laser Technology Co., Ltd.