Welcome!

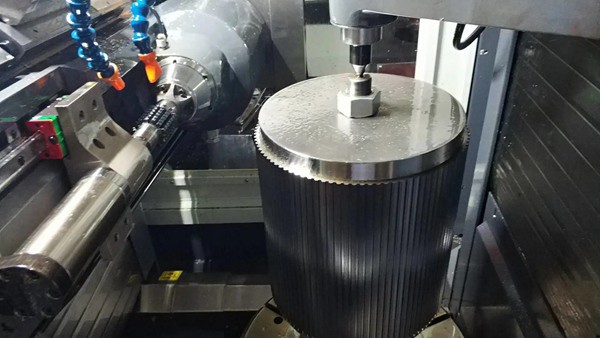

Automatic CNC Gear Hobbing Shaping Grinding Honing Worm Machine for Gear Processing Cutting Hobber

Product Description

The operation process of a gear hobbing machine mainly includes steps such as machine preparation, workpiece clamping, adjusting machining parameters, and starting machining. Firstly, it is necessary to place the gear hobbing machine on a stable foundation and secure it, and install the corresponding gear hobbing tools and fixtures. Then, inspect and adjust the gear hobbing machine to ensure that all parts are working properly. Next, place the gear to be machined into the workpiece fixture and clamp it, and set the machining parameters according to the shape and machining requirements of the gear. Finally, start the gear hobbing machine and start processing. If the processing quality does not meet the requirements, adjustments and corrections should be made in a timely manner.

Gear hobbing machines are widely used in various mechanical manufacturing industries such as automobiles, tractors, machine tools, engineering machinery, mining machinery, metallurgical machinery, petroleum, instruments, aircraft, and spacecraft. It can meet the machining needs of various cylindrical gears, bevel gears, and other toothed parts, providing high-quality gear transmission components for various mechanical equipment. The gear hobbing machine disperses cutting force at multiple rolling points through the rolling motion of the rollers, enabling high accuracy in the tooth shape and modulus of the gears. This high-precision machining method ensures the transmission efficiency and quality of gears.

Recommended Products

Recently Viewed

High Speed Gear Hobbing Hobber Machine for Shaft End Spline Gear Hobbing Machine

High Speed Gear Hobbing Hobber Machine for Shaft End Spline Gear Hobbing Machine China Manufacturer Gear Hobbing Shaping Grinding Honing Worm Machine for Gear Processing Cutting Hobber

China Manufacturer Gear Hobbing Shaping Grinding Honing Worm Machine for Gear Processing Cutting Hobber China Manufacturer Special Spline Hobbing Machine for Shaft End Spline Gear Hobbing Machine

China Manufacturer Special Spline Hobbing Machine for Shaft End Spline Gear Hobbing Machine Automatic CNC Special Spline Hobbing Machine for Gear Processing Cutting Hobber

Automatic CNC Special Spline Hobbing Machine for Gear Processing Cutting Hobber China Manufacturer Gear Hobbing Hobber Machine for Gear Processing Cutting Hobber

China Manufacturer Gear Hobbing Hobber Machine for Gear Processing Cutting Hobber

Contact Us

Shandong Raytu Laser Technology Co., Ltd.