Welcome!

ab valve, powder containment transfer valve

Product Description

Split butterfly valve, ab valve, αβ Valve -Conventional (Patent for invention technology)

Containment transfer technology

Fast and secure transfer for large quantitiesContainment transferEconomic solutionSupply solution for closed transfer of pharmaceutical materials

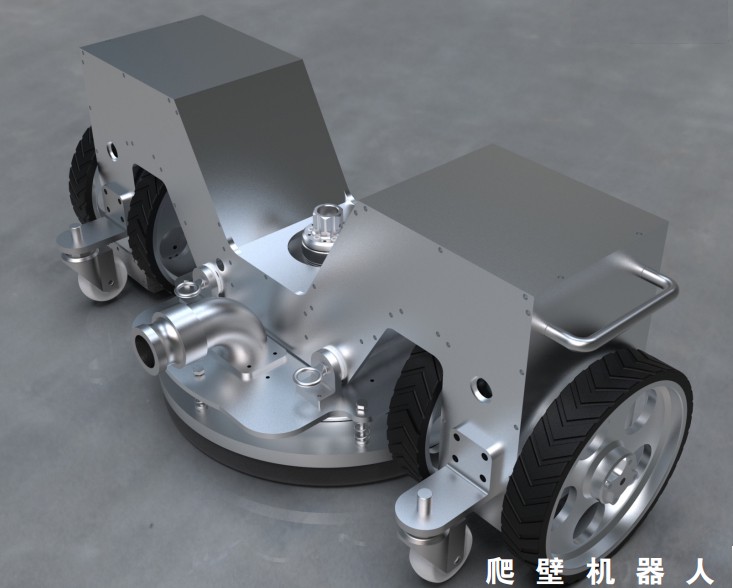

Split butterfly valve (Alpha Beta valve), is made up of an active and a passive split valve. It is produced by Geevo Co. which has own patent and brand. The transfer of material from one container to another container is being carried on sealing condition, and the sterile material transfer process guarantees the sterile situation won't be destroyed or avoid being spread of the powder, toxic materials in the container.

Split butterfly valve -Conventional: Accept wash and sterilization the exposed face by manual work to reach the normative requirement of material transfer.

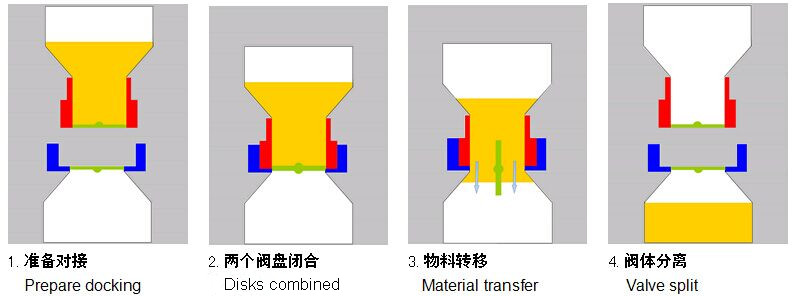

Interlock function: Only active valve and passive valve are mated completely, then can open the transfer channel.

When the transfer channel is opened, the passive valve cannot be disconnected.

Technical Parameter

- Valve disc surface sealing by metal to metal-Body material: 316L stainless steel-Sealing material: food grade FKM (meet FDA)-Standard clamp interface, accept customized corresponding connection-Outside of container operate valve switch and product transfer-Comply with the new version of GMP, FDA, EU production requirements

Operation process

Purpose of use

a. Protection of sterile product-Guarantee transfer process of sterile product avoiding being effected by outside microbeb. Operator protection- Avoiding leakage of toxic materials during transfer process which is harmful for peoplec. Eliminate loss of product yield during transferd. Effective dust control during transfer processe. Reduce the potential of product cross-contaminationf. Save the cost on equipment

Application case

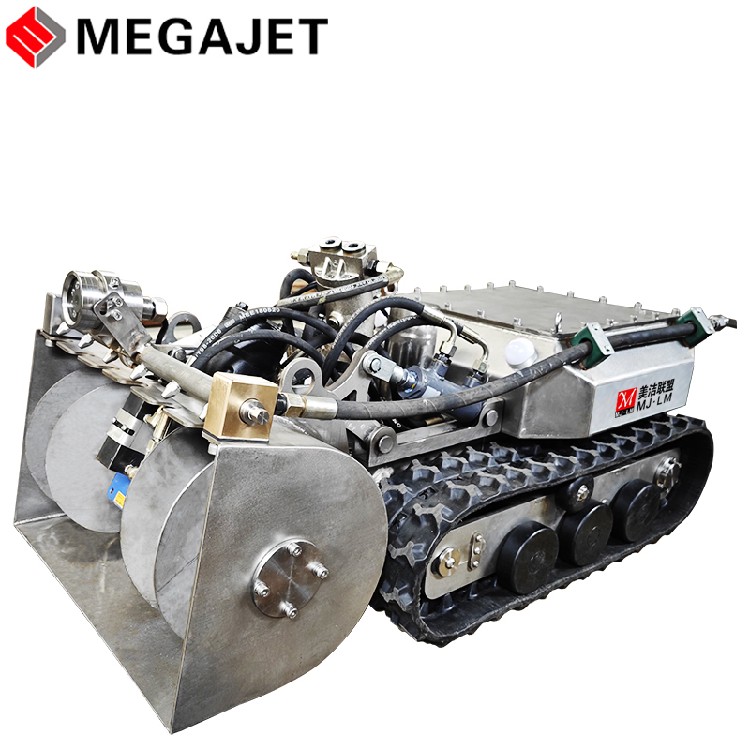

-Sterile API transfer and subpackage-Isolator charging and discharging-Contained dispensing, charging, discharging, sampling and milling-Containment transfer of sterile rubber plug -Transfer toxic product

Application

Pharmaceutical Biotechnology Chemical Food Beverage Nuclear CDC

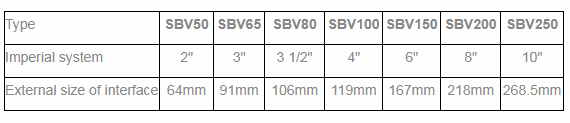

SpecificationStandard size: 50mm, 100mm, 150mm, 200mm, 250mm, 300mmConnections: PN6, PN10, ANSI#150, Tri-ClampCustomized size: Accept customized non-standard size

Recommended Products

Recently Viewed

Contact Us

HANGZHOU GEEVO TECHNOLOGY CO., LTD.