Welcome!

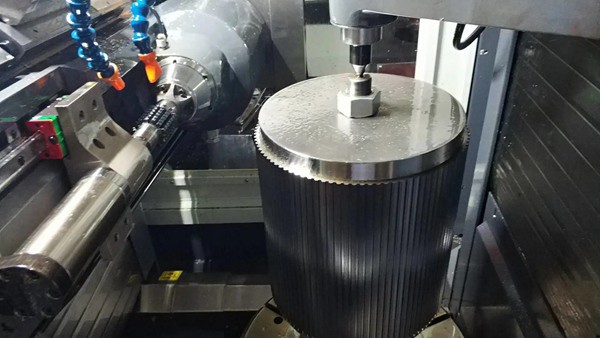

Automatic CNC Gear Hobbing Hobber Machine for Gear Processing Cutting Hobber

Product Description

Gear hobbing machines can process gears of various shapes and specifications, including straight teeth, helical teeth, bevel teeth, etc. This wide adaptability enables gear hobbing machines to meet the gear processing needs of different industries. Modern gear hobbing machines adopt advanced CNC technology, making operation more convenient and intuitive. Operators only need to input the corresponding processing parameters to achieve automated processing.

Gear hobbing machines can be divided into two types according to layout: vertical and horizontal. Large and medium-sized gear hobbing machines are mostly vertical, while small gear hobbing machines and gear hobbing machines specifically designed for processing long shaft gears are both horizontal. Vertical gear hobbing machines are divided into two types: worktable movement and column movement. In practical applications, choose the appropriate type of gear hobbing machine based on processing requirements and workpiece characteristics.

Recommended Products

Recently Viewed

High Speed Gear Hobbing Hobber Machine for Shaft End Spline Gear Hobbing Machine

High Speed Gear Hobbing Hobber Machine for Shaft End Spline Gear Hobbing Machine China Manufacturer Gear Hobbing Shaping Grinding Honing Worm Machine for Gear Processing Cutting Hobber

China Manufacturer Gear Hobbing Shaping Grinding Honing Worm Machine for Gear Processing Cutting Hobber China Manufacturer Special Spline Hobbing Machine for Shaft End Spline Gear Hobbing Machine

China Manufacturer Special Spline Hobbing Machine for Shaft End Spline Gear Hobbing Machine Automatic CNC Special Spline Hobbing Machine for Gear Processing Cutting Hobber

Automatic CNC Special Spline Hobbing Machine for Gear Processing Cutting Hobber China Manufacturer Gear Hobbing Hobber Machine for Gear Processing Cutting Hobber

China Manufacturer Gear Hobbing Hobber Machine for Gear Processing Cutting Hobber

Contact Us

Shandong Raytu Laser Technology Co., Ltd.