Welcome!

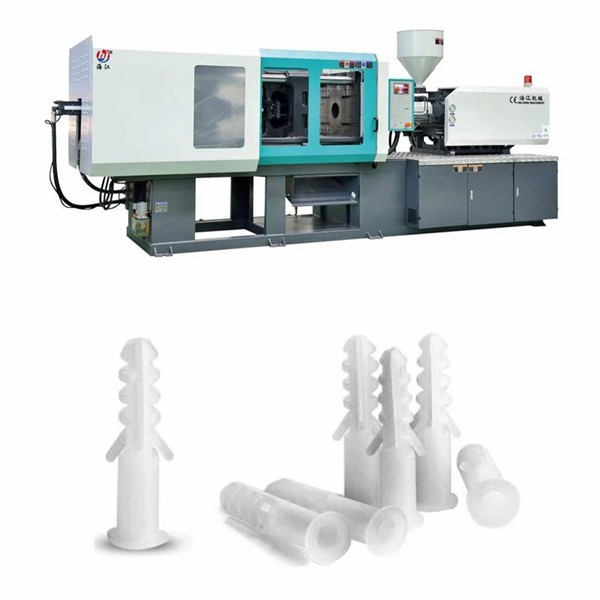

Factory Outlet Durable Plastic Chair Injection Moulding Machine

Product Description

The plastic chair molding machine is one of the key equipment for manufacturing plastic chairs, which processes plastic raw materials into the desired shape and size through specific working principles and technical means. With the continuous progress of technology and changes in market demand, plastic chair molding machines will continue to develop towards efficiency, environmental protection, and intelligence.

With the increasing awareness of environmental protection and the continuous emergence of new materials, the plastic chair forming machine industry is facing new development opportunities and challenges. In the future, environmental protection, energy conservation, efficiency, and intelligence will become important development directions for plastic chair forming machines. At the same time, with the intensification of market competition and the diversification of consumer demand, plastic chair molding machines will continuously introduce new products and technologies to meet the constantly changing and upgrading market.

Plastic chair molding machines can be classified according to different molding principles and technical characteristics, such as injection molding machines, compression molding machines, etc. Among them, injection molding machine is a commonly used type in the manufacturing of plastic chairs. It uses high-pressure injection to inject melted plastic materials into the mold, suitable for producing plastic chairs with complex shapes and precise dimensions.

The melt is fed into the mold through the injection or compression system of the molding machine. In the mold, the melt is subjected to pressure, filling the mold cavity and forming the shape of a plastic chair. After a period of cooling and solidification, the melt transforms into a solid plastic chair. Finally, open the mold and take out the formed plastic chair.

Select suitable plastic raw materials for molding and prepare them according to the requirements of the molding machine. Ensure that the power switch of the molding machine is turned off, then turn on the main power switch of the machine. Adjust the heating temperature and time of the machine according to the requirements of the selected raw materials, and heat the heating element to the desired temperature. Put the prepared plastic raw materials into the feeding port to ensure that they evenly enter the feeding area.

Recommended Products

Recently Viewed

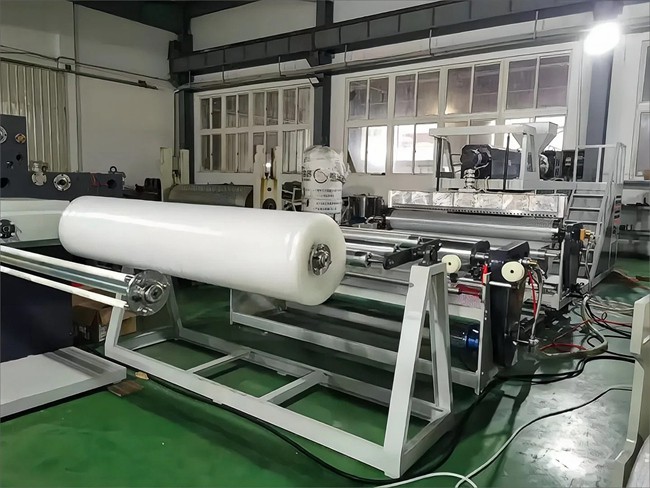

High Quality Three Layers PE Air Bubble Film Extruder Machine

High Quality Three Layers PE Air Bubble Film Extruder Machine High Speed Filmplastic Bubble Film Machine for Aluminum Laminating Machine

High Speed Filmplastic Bubble Film Machine for Aluminum Laminating Machine High Speed 3-7 Layers Composite Air Bubble Film Making Machine

High Speed 3-7 Layers Composite Air Bubble Film Making Machine High Quality 3-7 Layers Composite Air Bubble Film Making Machine

High Quality 3-7 Layers Composite Air Bubble Film Making Machine Factory Direct Three Layers PE Air Bubble Film Extruder Machine

Factory Direct Three Layers PE Air Bubble Film Extruder Machine

Contact Us

Wenling Rising Sun Rotomolding Technology Co., Ltd.