Welcome!

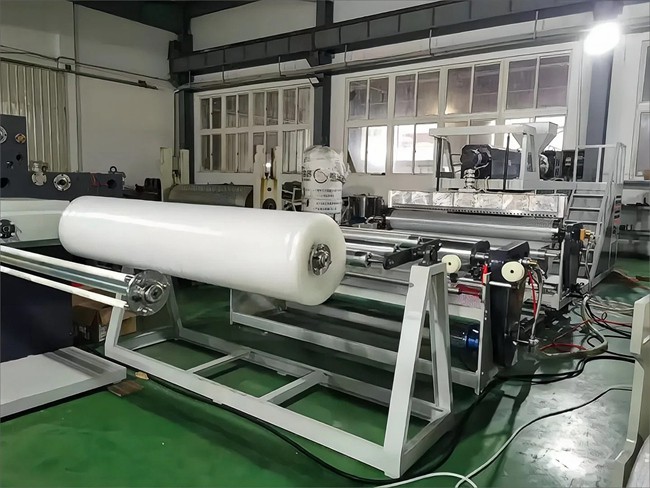

Manufacture Price Compound 3-Layer Air Bubble Film Making Machine

Product Description

Characteristics of Bubble Film

Anti pressure, moisture-proof, and shockproof: The middle layer of the bubble film is filled with air, and it is lightweight and elastic, with good shockproof, anti damage, and cushioning properties.

Waterproof and moisture-proof: Bubble film can effectively prevent moisture infiltration and protect packaging items from moisture.

Environmentally friendly and non-toxic: Bubble wrap is usually made of environmentally friendly materials such as polyethylene, which is non-toxic and odorless, and meets environmental requirements.

Product Features

Stable performance: Bubble film machines usually have stable machine performance and can continuously and efficiently produce bubble films.

Strong durability: The equipment structure design is scientific, practical, and reasonable, with high durability.

Wide applicability: Bubble wrap is widely used in packaging fields across multiple industries due to its excellent shock resistance, damage resistance, cushioning, moisture resistance, and other properties.

Extrusion bubble film machine is a specialized equipment that uses extrusion and stretching methods to produce bubble film. The core part of the machine is the extruder, which deforms polymer materials (such as polyethylene) by squeezing them to produce the raw material for bubble wrap. The extruder consists of a melting system, a filtering system, an extrusion system, and a regulating system. The melting system heats and melts plastic particles, the filtering system removes impurities and defective materials, the extrusion system applies pressure to the molten material, and the regulating system controls parameters such as temperature, pressure, and speed. The melted polymer material is then fed into the bubble mold through a nozzle for bubble forming operation.

Recommended Products

Recently Viewed

High Quality Three Layers PE Air Bubble Film Extruder Machine

High Quality Three Layers PE Air Bubble Film Extruder Machine High Speed Filmplastic Bubble Film Machine for Aluminum Laminating Machine

High Speed Filmplastic Bubble Film Machine for Aluminum Laminating Machine High Speed 3-7 Layers Composite Air Bubble Film Making Machine

High Speed 3-7 Layers Composite Air Bubble Film Making Machine High Quality 3-7 Layers Composite Air Bubble Film Making Machine

High Quality 3-7 Layers Composite Air Bubble Film Making Machine Factory Direct Three Layers PE Air Bubble Film Extruder Machine

Factory Direct Three Layers PE Air Bubble Film Extruder Machine

Contact Us

Ruian Hualiang Machinery Co.,Ltd.