Welcome!

Wholesale Price Durable Plastic Chair Injection Moulding Machine

Product Description

The plastic chair molding machine is one of the key equipment for manufacturing plastic chairs, which processes plastic raw materials into the desired shape and size through specific working principles and technical means. With the continuous progress of technology and changes in market demand, plastic chair molding machines will continue to develop towards efficiency, environmental protection, and intelligence.

Plastic chair molding machine is a specialized mechanical equipment used for manufacturing plastic chairs. Plastic chair molding machine is a mechanical equipment that processes plastic raw materials into the shape required for plastic chairs. It heats plastic raw materials to a molten state, then injects or presses them into a mold, undergoes a cooling and curing process, and forms the final plastic chair product.

Select suitable plastic raw materials for molding and prepare them according to the requirements of the molding machine. Ensure that the power switch of the molding machine is turned off, then turn on the main power switch of the machine. Adjust the heating temperature and time of the machine according to the requirements of the selected raw materials, and heat the heating element to the desired temperature. Put the prepared plastic raw materials into the feeding port to ensure that they evenly enter the feeding area.

Plastic products have penetrated into every aspect of our lives, from daily necessities to high-tech products, all of which cannot be separated from the widespread application of plastics. The importance of plastic molding machines, as the key equipment for manufacturing these plastic products, is self-evident. This article will provide a detailed introduction to the principle, classification, operation methods, and market development trends of plastic molding machines.

Recommended Products

Recently Viewed

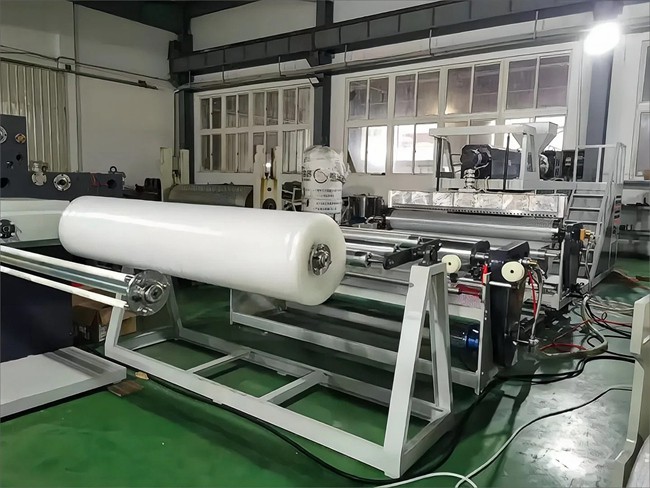

High Quality Three Layers PE Air Bubble Film Extruder Machine

High Quality Three Layers PE Air Bubble Film Extruder Machine High Speed Filmplastic Bubble Film Machine for Aluminum Laminating Machine

High Speed Filmplastic Bubble Film Machine for Aluminum Laminating Machine High Speed 3-7 Layers Composite Air Bubble Film Making Machine

High Speed 3-7 Layers Composite Air Bubble Film Making Machine High Quality 3-7 Layers Composite Air Bubble Film Making Machine

High Quality 3-7 Layers Composite Air Bubble Film Making Machine Factory Direct Three Layers PE Air Bubble Film Extruder Machine

Factory Direct Three Layers PE Air Bubble Film Extruder Machine

Contact Us

Wenling Rising Sun Rotomolding Technology Co., Ltd.