Welcome!

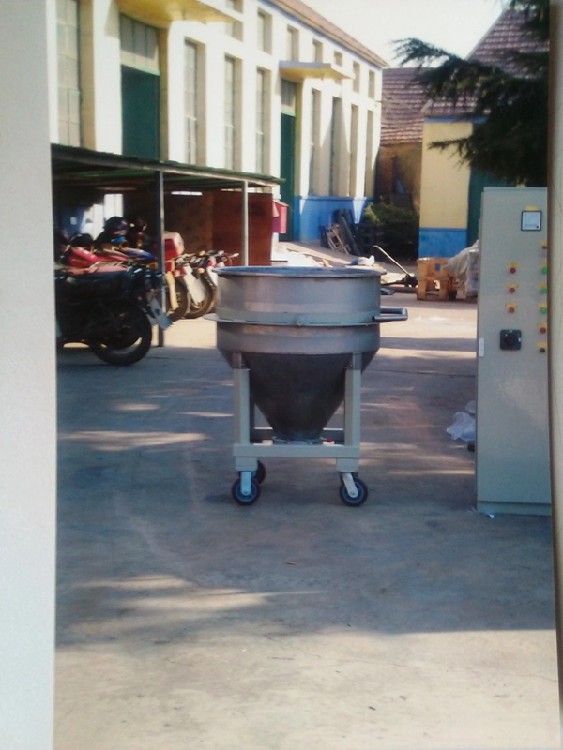

Hot Sale Masterbatch Powders China High Speed Mixer

Product Description

In the process of coating production, the role of the coating mixer cannot be ignored. It can not only ensure the uniform mixing of coating materials, but also improve the quality and performance of coatings. Therefore, choosing a high-performance coating mixer is crucial for coating production enterprises. Meanwhile, with the continuous development of the paint industry, the technology and performance of paint mixers are also constantly improving to meet the industry's demand for high-quality coatings.

A paint mixer usually consists of a mixing drum, a mixing device, a feeding and discharging system, and a control system. The mixing bucket is the main place for coating mixing, and its material is wear-resistant and corrosion-resistant to meet the mixing needs of different coating raw materials. The mixing device is located inside the mixing drum and is driven by an electric motor to rotate or vibrate, forming convection and shear effects on the coating materials in the mixing drum, achieving uniform mixing. The feed and discharge system is responsible for the addition of coating raw materials and the discharge of mixed coatings. The control system is responsible for the automation operation of the entire mixing process, including the setting of parameters such as mixing speed and mixing time.

The paint mixer is one of the core equipment in the paint production process. Its efficient mixing, simple operation, strong durability, and strong adaptability make it an indispensable and important equipment for paint production enterprises. A paint mixer is a mechanical equipment specifically used in the paint production process, whose main function is to evenly mix paint raw materials to ensure the quality and performance of the paint. This type of equipment plays an important role in industries such as coatings, paints, pigments, plastics, and rubber.

The paint mixer can achieve uniform mixing of paint raw materials in a short period of time and improve production efficiency through carefully designed mixing devices and control systems. The control system adopts advanced automation technology, making the operation of the paint mixer more convenient and feasible.

As one of the important equipment in the coating manufacturing industry, the powder coating mixer has the characteristics of efficient mixing, excellent material quality, high degree of automation, and compact structure. With the continuous development of the coating manufacturing industry, the application fields of powder coating mixers will also become increasingly widespread. The paint mixer is an indispensable and important equipment in the paint production process. Its main function is to mix various paint raw materials evenly to achieve the predetermined paint quality and performance. The following is a detailed introduction to the paint mixer.

Recommended Products

Recently Viewed

Wholesale Thermoplastic Master Batch Powder Coating Processing Equipment

Wholesale Thermoplastic Master Batch Powder Coating Processing Equipment High Quality Masterbatch Powders China High Speed Mixer

High Quality Masterbatch Powders China High Speed Mixer High Quality Thermoplastic Master Batch Powder Coating Processing Equipment

High Quality Thermoplastic Master Batch Powder Coating Processing Equipment Hot Sale Powder Coating/Paint Producing/Manufacturing/Production/Making High Speed Pre-Mixer

Hot Sale Powder Coating/Paint Producing/Manufacturing/Production/Making High Speed Pre-Mixer Wholesale Thermoplastic Master Batch Powder Coating Processing Equipment

Wholesale Thermoplastic Master Batch Powder Coating Processing Equipment

Contact Us

Jiangmen Homemaster Electric Motors and Appliances Manufacturing Company Limited