Welcome!

Wholesale Thermoplastic Master Batch Powder Coating Processing Equipment

Product Description

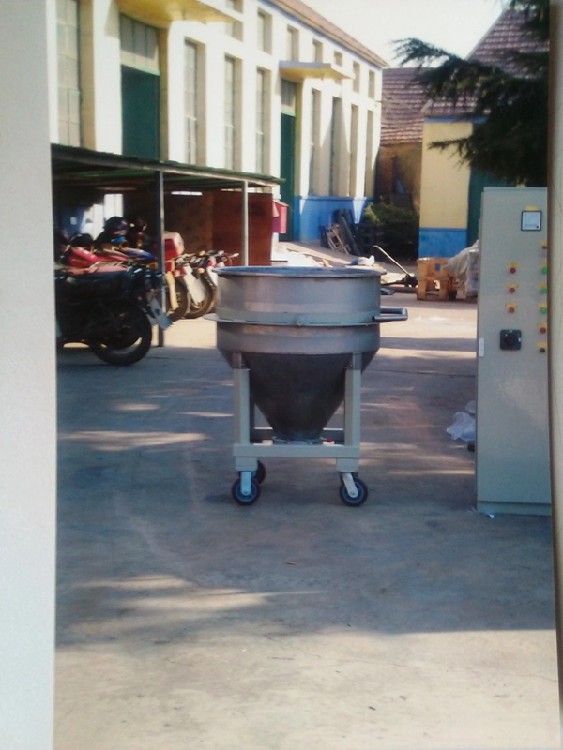

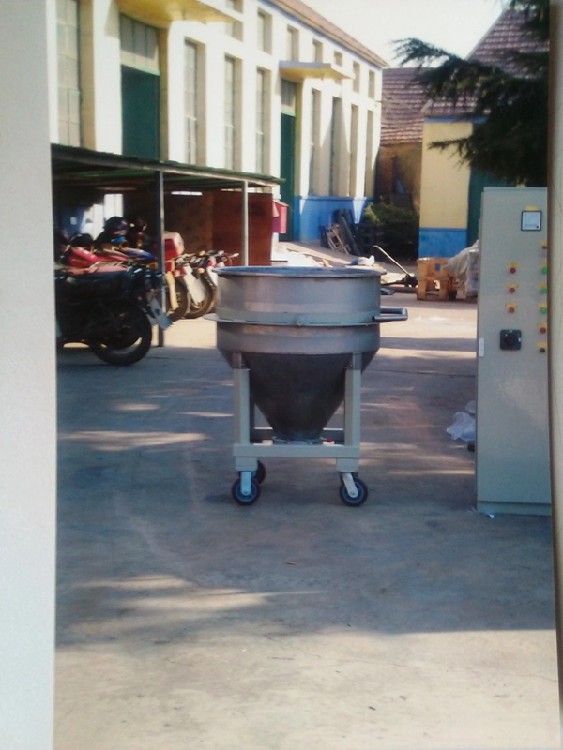

In the process of coating production, the role of the coating mixer cannot be ignored. It can not only ensure the uniform mixing of coating materials, but also improve the quality and performance of coatings. Therefore, choosing a high-performance coating mixer is crucial for coating production enterprises. Meanwhile, with the continuous development of the paint industry, the technology and performance of paint mixers are also constantly improving to meet the industry's demand for high-quality coatings.

The paint mixer has various characteristics, such as efficient mixing, easy operation, strong durability, and strong adaptability. It can achieve uniform mixing of coating materials in a short period of time, improving production efficiency. Meanwhile, the easy-to-use control system reduces the difficulty of operation, making the equipment easy to use and maintain. In addition, the paint mixer is made of wear-resistant and corrosion-resistant materials, which can adapt to the mixing needs of various paint raw materials and ensure the long-term stable operation of the equipment.

The paint mixer is one of the core equipment in the paint production process. Its efficient mixing, simple operation, strong durability, and strong adaptability make it an indispensable and important equipment for paint production enterprises. A paint mixer is a mechanical equipment specifically used in the paint production process, whose main function is to evenly mix paint raw materials to ensure the quality and performance of the paint. This type of equipment plays an important role in industries such as coatings, paints, pigments, plastics, and rubber.

The working principle of the paint mixer is relatively simple and efficient. When the coating raw materials enter the mixing drum through the feeding system, the control system starts the motor to drive the mixing device to start working. The mixing device forms convection and shear effects on the coating raw materials in the mixing drum through rotation or vibration, thereby achieving uniform mixing. When the mixing reaches the predetermined uniformity, the control system turns off the motor, opens the discharge system, and discharges the mixed paint.

The powder coating mixer can achieve uniform mixing of coating materials and improve production efficiency in a short period of time through a high-speed rotating mixer. Mixing drums and mixers are usually made of wear-resistant and corrosion-resistant materials, which can meet the mixing needs of various coating materials. The control system can achieve automated operation of the entire mixing process, reduce operational difficulty, and improve production efficiency. Powder coating mixers usually adopt a compact structural design, with a small footprint, making them easy to install and transport.

Recommended Products

Recently Viewed

Wholesale Thermoplastic Master Batch Powder Coating Processing Equipment

Wholesale Thermoplastic Master Batch Powder Coating Processing Equipment High Quality Masterbatch Powders China High Speed Mixer

High Quality Masterbatch Powders China High Speed Mixer High Quality Thermoplastic Master Batch Powder Coating Processing Equipment

High Quality Thermoplastic Master Batch Powder Coating Processing Equipment Hot Sale Powder Coating/Paint Producing/Manufacturing/Production/Making High Speed Pre-Mixer

Hot Sale Powder Coating/Paint Producing/Manufacturing/Production/Making High Speed Pre-Mixer Wholesale Thermoplastic Master Batch Powder Coating Processing Equipment

Wholesale Thermoplastic Master Batch Powder Coating Processing Equipment

Contact Us

Jiangmen Homemaster Electric Motors and Appliances Manufacturing Company Limited