Welcome!

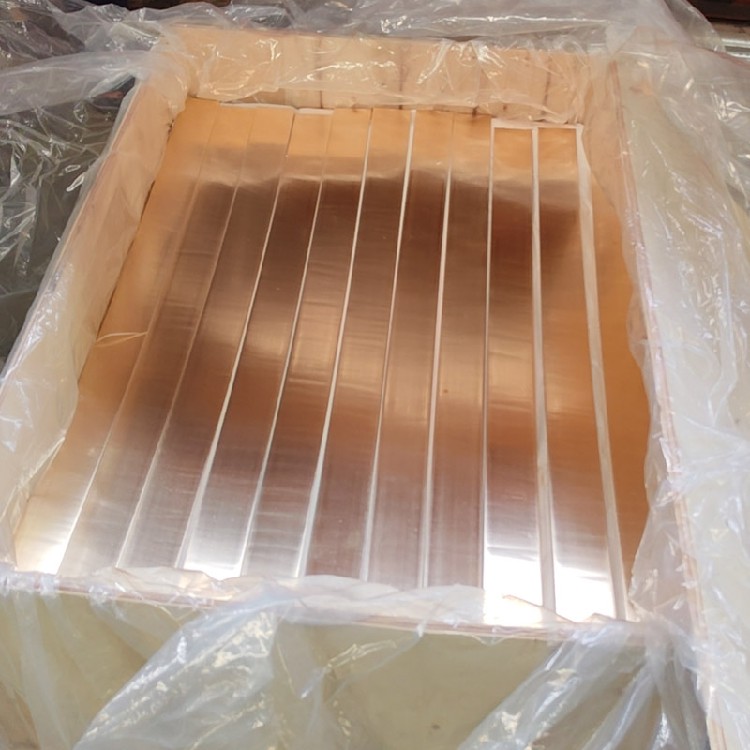

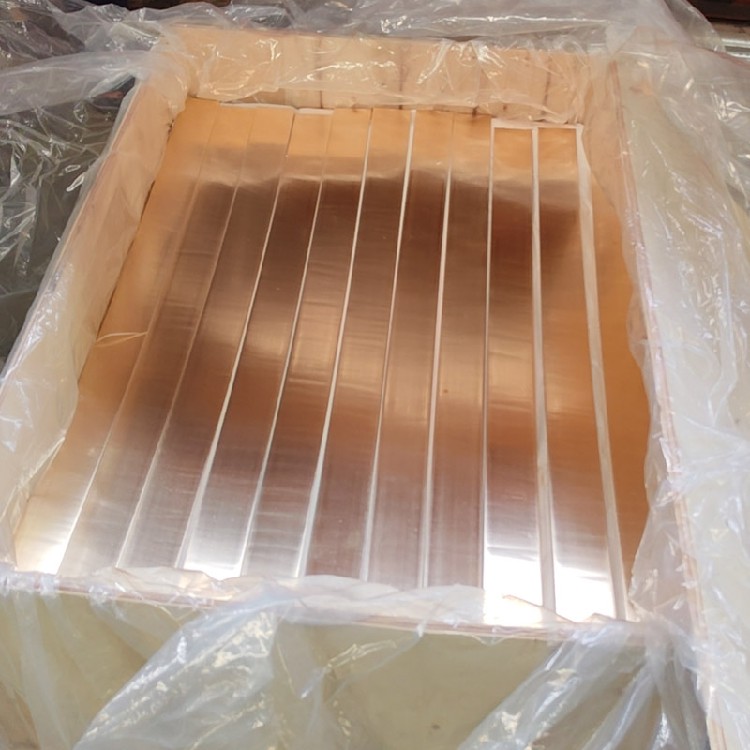

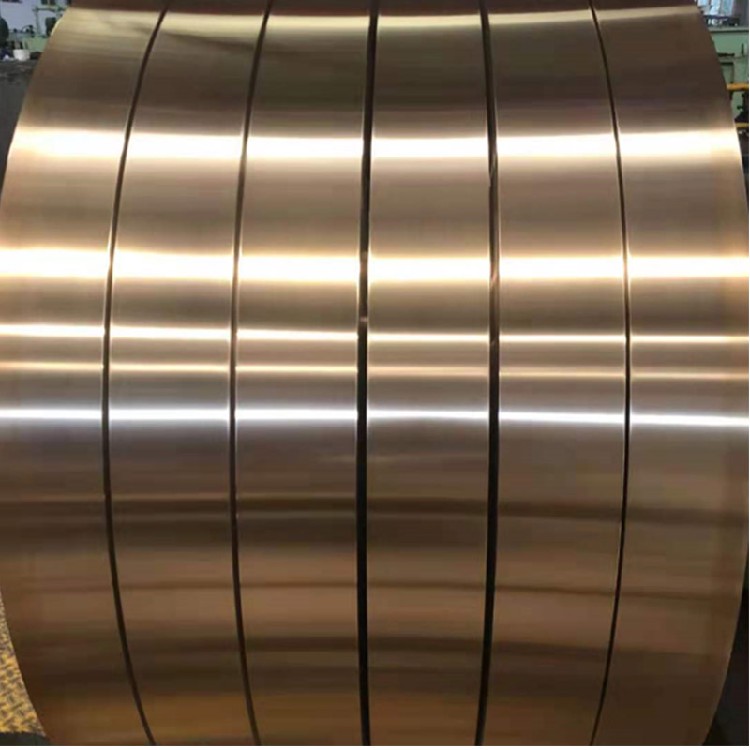

copper-clad steel sheet Coating Gilding Metal (Brass 90 clad on both sides) H90/F11/H9 C22000

Basic Info

| Thickness | 0.5-1.4mm | Width | 135mm | ||

|---|---|---|---|---|---|

Product Description

Copper-clad Steel Sheet

Coating Gilding Metal (Brass 90 clad on both sides)

H90/F11/H90,0.5mm,0.8mm,1.4mm

1、 Product Description

Material grade: Coating Gilding Metal (Brass 90 class on both sides)

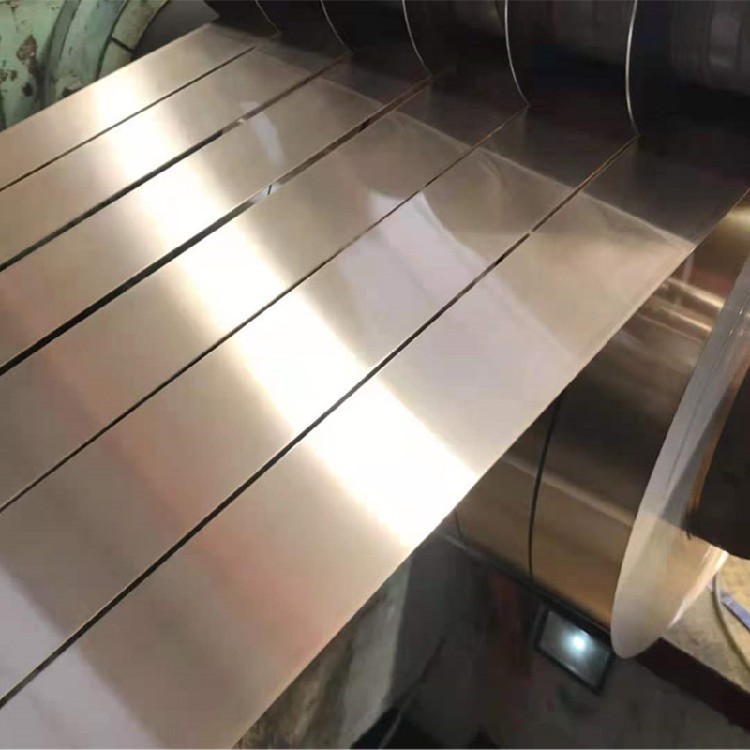

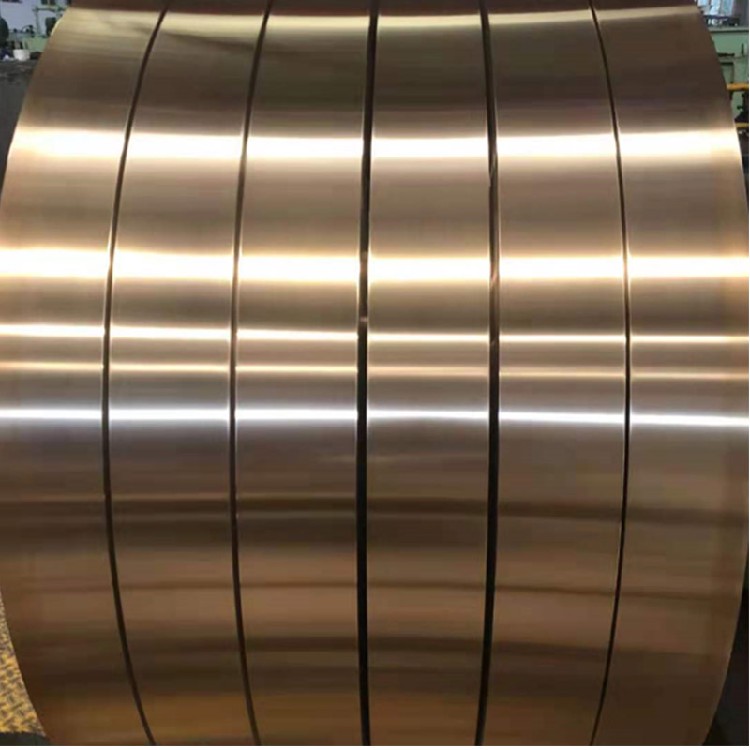

Brass/carbon steel/brass H90/F11/H90, using F18 deep drawing steel as the base material, double-sided H90 (C22000) brass cold rolling and rolling composite rolling, metal alloy composite material. Partially replace H90 pure brass for use. Intelligent composite, reducing costs and increasing efficiency. Assist small and medium-sized enterprises: new quality productivity, high-quality development.

2、 Mechanical properties, mechanical parameters. Technical requirements.)

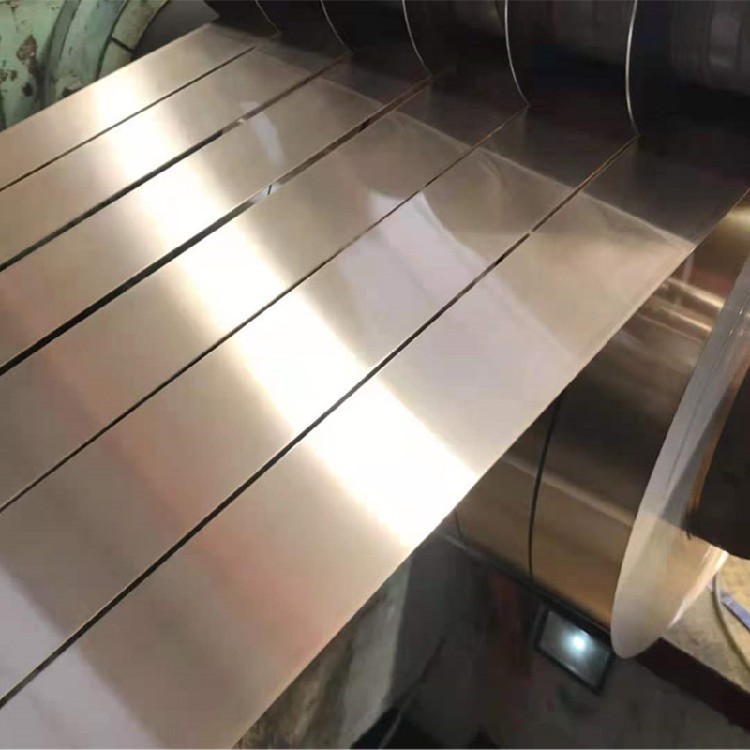

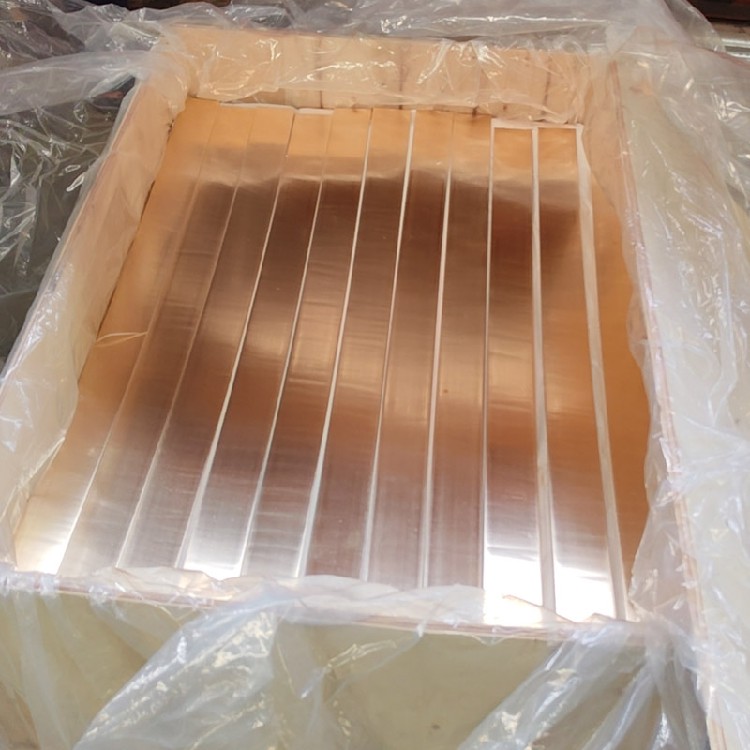

Thickness specification: 1.7-3.2mm, customized as needed.

Width: 450-600mm, can be divided into strips, with flat panels.

Length: can be flattened by 1000mm or 2000mm as needed, with roll material supply

Elongation: Over 43%

Tensile strength (M.p): 265-365

Status: Half hard state delivered in annealed state.

3、 Industry applications and uses:

Electrical and electrical stamping parts, connectors, terminal blocks, conductive sheets. Automotive power batteries, power electronics, screen doors, hardware stamping parts, decorative panels, etc.

4、 Advantages:

High strength, corrosion resistance, easy processing, stretching, deep drawing, punching, higher strength, better cost-effectiveness, reduced weight, and reduced cost

- MOHOTANG Technology focuses on the research and development of cold rolling, hot rolling, and casting metal composite technology:First, copper-clad steel composite copper new materials: copper steel strip T2/H65/H90, brass steel strip H65/IF/H65, H90/F18/H90.Two-layer, three-layer, five-layer, multi-layer stainless steel composite materials, aluminum-steel, aluminum-stainless steel composite plate strips, stainless steel aluminum pots), connecting plates.Third, T2/1050/3003 copper-aluminum new energy automotive and other metal composite materials research and development, supply.Products are applied in electrical and electronic, electronic hardware stamping parts, 3C (computer, communication, consumer electronics), pot kitchenware, new energy automotive, hardware stamping parts machining and other fields, committed to providing metal new materials services and solutions for small and medium-sized manufacturing customers around the world, reducing costs and improving efficiency, innovation and progress.

- Technology R&D concept

- Laminated metal composites are materials composed of two or more layers of different metals, which are processed by rolling deformation at a recrystallization temperature.Their performance is superior to that of single metals, and different metal layers can be selected according to needs, making metal laminated composites have a variety of excellent properties, which has been widely applied in areas requiring wear resistance, corrosion resistance, impact resistance, high thermal conductivity, electromagnetic properties, strength, toughness, and so on.

Recommended Products

Recently Viewed

C27000 Brass Steel Brass Copper-Steel Clad Plate 0.15mm C2700/If/ C2700 H65 Alloy

C27000 Brass Steel Brass Copper-Steel Clad Plate 0.15mm C2700/If/ C2700 H65 Alloy TOMBAC STEEL TOMBAC TOMBAC STEEL TOMBAC-St-Cuzn10 H90/If/H90 C22000 /If/ C22000 Coating Gilding Metal Brass 90 Clad on Both Sides

TOMBAC STEEL TOMBAC TOMBAC STEEL TOMBAC-St-Cuzn10 H90/If/H90 C22000 /If/ C22000 Coating Gilding Metal Brass 90 Clad on Both Sides copper-clad steel sheet Coating Gilding Metal (Brass 90 clad on both sides) H90/F11/H9 C22000

copper-clad steel sheet Coating Gilding Metal (Brass 90 clad on both sides) H90/F11/H9 C22000 copper-clad steel sheet Coating Gilding Metal (Brass 90 clad on both sides) H90/F18/H9 3.1mm

copper-clad steel sheet Coating Gilding Metal (Brass 90 clad on both sides) H90/F18/H9 3.1mm

Contact Us

Wenzhou Mohotang Technology Co., Ltd