Welcome!

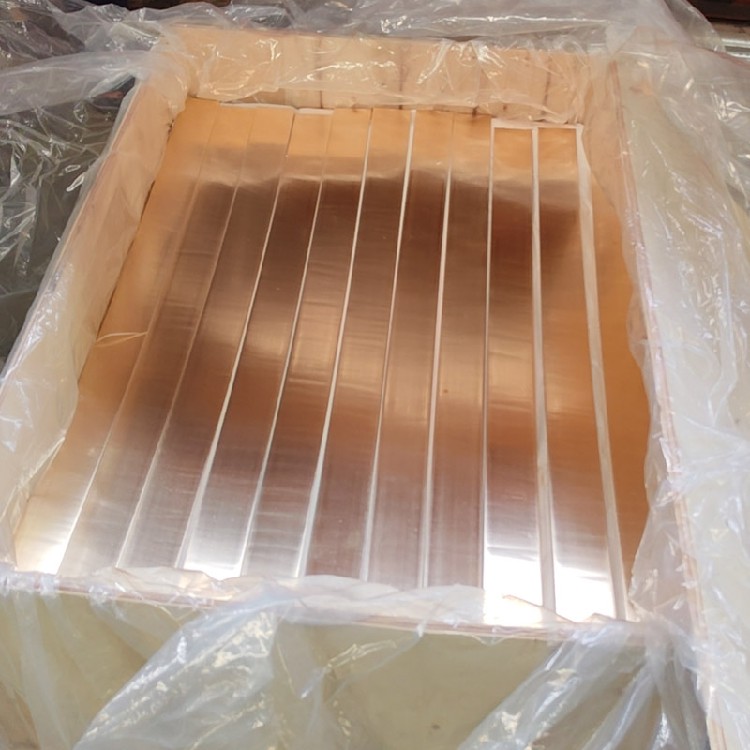

TOMBAC STEEL TOMBAC TOMBAC STEEL TOMBAC-St-Cuzn10 H90/If/H90 C22000 /If/ C22000 Coating Gilding Metal Brass 90 Clad on Both Sides

Basic Info

| Thickness | 0.1-4.0mm | Width | 139.5 | ||

|---|---|---|---|---|---|

Product Description

TOMBAC - STEEL - TOMBAC

TOMBAC - STEEL - TOMBAC

Multilayer strips CuZn10-St-CuZn10. Technical Requirements. (H90/IF/H90,C22000 /IF/ C22000).

| Coating Gilding Metal (Brass 90 clad on both sides) |

Production process:

Cold rolling and rolling composite

Description

Multilayer bimetal strip CuZn10-St-CuZn10 is made of low-carbon steel strip, clad on both sides with CuZn10.

Composition

| H1 | TOMBAC CuZn10 | |||

| H | STEEL | |||

| H2 | TOMBAC CuZn10 |

- Base - low-carbon quality steel, grade IF(Interstitial Free Steel)/SPHC/ DC04, with chemical composition acc. to GBT3524-2015,

- Hot-rolled carbon and low alloy structural steel strips

- Coating - brass CuZn10 with chemical composition acc. to GBT3524-2015,.

The thickness of cladding layers h1 and h2 is the same for both sides and varies from 3.5to 4% of the finished strip thickness. Upon customer's request, the thickness of the cladding layer can be up to 10% on each side.

Classification and range

By state of material:

- soft - Annealing ,HV90-110,

- half-hard ,HV 110-140

- hard - T,HV 160-180

By type of edge:

- sheared edge - O

- mill edge - Н

Technical characteristics

| Type | ThicknessH, mm | Thicknesstolerance, mm | Width B, mm | Widthtolerance, mm | Length, mm | Internal coil diameter ØID, mm | Coilweight, kg |

| Strip | 0,10 - 0,80 | from (±0,005) to (±0,03) | 6 - 60 | (±0,1) | off-gage | 80 / 100 / 200 / 300 / 400 | 10 - 100 |

| 60 - 220 | from (±0,1) to (±0,2) | 50 - 500 | |||||

| 0,81 - 4.00 | from (±0,03) to (±0,005) | 20 - 60 | (±0,1) | off-gage | 300 / 400 / 500 | 10 - 100 | |

| 60 - 220 | from (±0,1) to (±0,2) | 50 - 500 | |||||

| Band | 0,50 - 4,00 | from (±0,02) to (±0,005) | 50 - 220 | from (±0,1) to (±0,2) | 1000 - 3000 | - | - |

For strips with mill edge width tolerance is (±1,0) mm.

Production of other sizes according to the agreed tolerance is possible.

Mechanical properties

| Strip state | Ultimate tensile strength σB, МPа | Elongation δ, % |

| Soft (М) | 290 ÷ 410 | ≥32 |

| Soft-tempered (Д) | 320 ÷ 440 | ≥26 |

| Half-hard (П) | 340 ÷ 470 | ≥20 |

| Hard (Т) | 410 ÷ 570 | ≥8 |

| Extra-hard - (ОТ) | 510 ÷ 640 | ≥2 |

Application

For manufacturing of electrical engineering and automotive industry products, cable armouring.

Brass H90 is a common brass with a copper content of 89.0-91.0%, also known as C22000 or Gold Medal Brass. Its chemical composition is mainly copper and zinc, with 0.1% iron and 0.2% total impurities. It has a fine luster, good processability, and corrosion resistance, and is suitable for use in cold and hot pipe materials, radiator wave bands, and other scenarios. It is widely used in the manufacturing of building materials, zipper heads, and automotive lamp caps.

This material exhibits a lower wear rate in sandy environments, with a 33% reduction in wear rate compared to non sandy environments under a load of 2.45N [1]. The use of extrusion molding technology can reduce the number of production processes from 44 to 27, improve material utilization, and reduce unit costs [2]. When welding with D60 steel, there is a diffusion phenomenon of Fe/Cu elements at the interface, and the diffusion strength of Fe towards the brass side is higher than that towards the reverse diffusion [4]. Compared to H96 brass, H90 has slightly higher strength and can be extended to the fields of bimetallic sheets and handicrafts [3].

Chinese name brass H90

Nickname C22000

P b0.05

Z n margin

National standard GB/T 5231-2002 "Grades and Chemical Composition of Processed Copper and Copper Alloys"

F e0.05

Magazine total 0.3

C u89.0~91.0

Brass H90 has a fine luster, good processability, stretchability, and corrosion resistance. Not easily broken due to aging, can be applied to building materials, personal accessories, cosmetic accessories, water heater tanks, horn locks, zipper heads, bullet heads, and car light caps. Brass H90 has good mechanical properties and corrosion resistance, can withstand cold and hot pressing processing, and is easy to tin plate. It is mainly used for radiator cold and hot pipe materials and radiator wave bands. Brass H90 and H96 have similar performance, slightly higher strength, and can be plated with metal. They are used for various water supply and drainage pipes, bimetallic sheets and medals, artworks, etc.

Chemical composition (%):

Cu :89.0-91.0

Fe :0.05

Pb:0.05

Zn: Excess

Total impurities: 0.3

Category: Copper Zinc Alloy - Ordinary Brass

Reference: GB/T 5231-2002 "Grades and Chemical Composition of Processed Copper and Copper Alloys"

Recommended Products

Recently Viewed

C27000 Brass Steel Brass Copper-Steel Clad Plate 0.15mm C2700/If/ C2700 H65 Alloy

C27000 Brass Steel Brass Copper-Steel Clad Plate 0.15mm C2700/If/ C2700 H65 Alloy TOMBAC STEEL TOMBAC TOMBAC STEEL TOMBAC-St-Cuzn10 H90/If/H90 C22000 /If/ C22000 Coating Gilding Metal Brass 90 Clad on Both Sides

TOMBAC STEEL TOMBAC TOMBAC STEEL TOMBAC-St-Cuzn10 H90/If/H90 C22000 /If/ C22000 Coating Gilding Metal Brass 90 Clad on Both Sides copper-clad steel sheet Coating Gilding Metal (Brass 90 clad on both sides) H90/F11/H9 C22000

copper-clad steel sheet Coating Gilding Metal (Brass 90 clad on both sides) H90/F11/H9 C22000 copper-clad steel sheet Coating Gilding Metal (Brass 90 clad on both sides) H90/F18/H9 3.1mm

copper-clad steel sheet Coating Gilding Metal (Brass 90 clad on both sides) H90/F18/H9 3.1mm

Contact Us

Wenzhou Mohotang Technology Co., Ltd