Welcome!

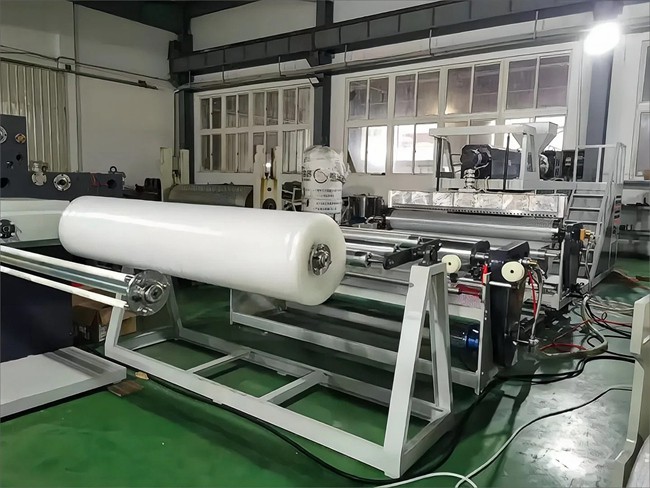

China Factory Price Rsd-180 EPE PE Foam Sheet Making Machine

Product Description

EPE foaming machine adopts advanced heating and cooling technology, which can significantly reduce energy consumption and improve production efficiency while ensuring production quality. This not only reduces the operating costs of enterprises, but also meets the current green low-carbon environmental protection concept. Modern EPE foaming machines are generally equipped with advanced automation control system, which can realize the fully automated production process from raw material mixing, heating and melting, foam molding to cooling and shaping. This not only reduces the difficulty and labor intensity of manual operation, but also improves the stability and consistency of products.

The working principle of EPE foaming machine is based on the physical or chemical foaming process of polyethylene material. Inside the machine, polyethylene particles are mixed with foaming agent, catalyst and other auxiliary materials in a certain proportion and then enter the heating system. Under the action of high temperature, the polyethylene particles gradually melt and react with the blowing agent to produce a large number of tiny bubbles. With the expansion and diffusion of the bubbles, the molten polyethylene forms a porous mesh structure, i.e. EPE pearl cotton. Subsequently, the pearl cotton is rapidly cured and shaped by the cooling system, and finally becomes a finished product after cutting and packaging.

Recommended Products

Recently Viewed

High Quality Three Layers PE Air Bubble Film Extruder Machine

High Quality Three Layers PE Air Bubble Film Extruder Machine High Speed Filmplastic Bubble Film Machine for Aluminum Laminating Machine

High Speed Filmplastic Bubble Film Machine for Aluminum Laminating Machine High Speed 3-7 Layers Composite Air Bubble Film Making Machine

High Speed 3-7 Layers Composite Air Bubble Film Making Machine High Quality 3-7 Layers Composite Air Bubble Film Making Machine

High Quality 3-7 Layers Composite Air Bubble Film Making Machine Factory Direct Three Layers PE Air Bubble Film Extruder Machine

Factory Direct Three Layers PE Air Bubble Film Extruder Machine

Contact Us

Zhejiang Benfan Machinery Co., Ltd.