Welcome!

China Supplier Aluminum Cladding Honeycomb Composite Sandwich Wall Panel for Facades

Product Description

The market demand for aluminum composite sandwich honeycomb panels is growing, and the price varies according to brand, specification, material and other factors. According to the recent market offer, the price of aluminum composite sandwich honeycomb panel ranges from tens to hundreds of yuan per square meter. Specific prices need to be quoted and compared according to actual demand and suppliers. Aluminum composite sandwich honeycomb panel has become one of the important materials in modern construction, transportation and other fields with its excellent performance characteristics and wide range of applications.

Aluminum composite sandwich honeycomb panel is widely used in the fields of building curtain wall, ceiling, indoor partition, external wall insulation, etc., to improve the aesthetics and functionality of the building. In vehicle manufacturing, aluminum composite sandwich honeycomb panels can be used in the interior, doors, roofs and other parts of the car to reduce the weight of the vehicle and improve safety performance. In shipbuilding, aluminum composite sandwich honeycomb panels can be used in the hull structure, decks, cabins and other parts of the ship to improve the ship's carrying capacity and resistance to wind and waves.

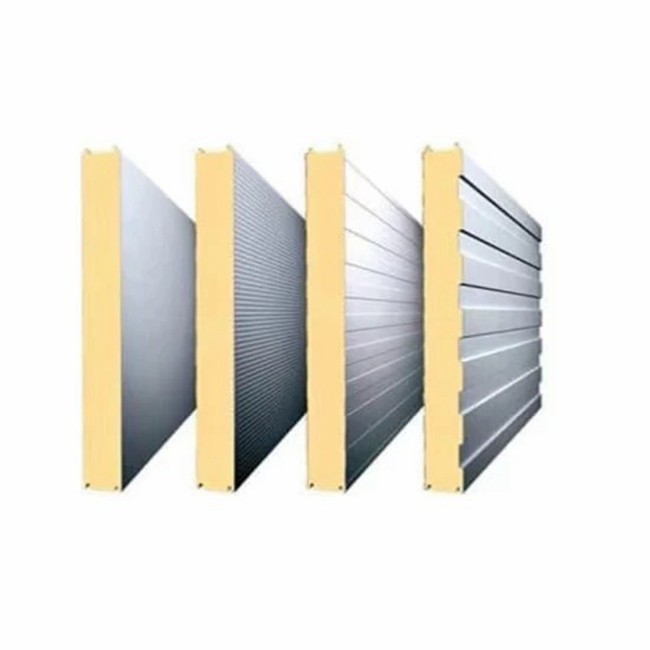

Aluminum composite sandwich honeycomb panel by the upper and lower layers of aluminum and the middle of the honeycomb aluminum core through a special bonding technology composite. The surface aluminum plate is usually 0.5mm to 1.5mm thickness of aluminum alloy sheet, with good fire, weather and corrosion resistance. The intermediate honeycomb aluminum core consists of many hexagonal aluminum honeycomb holes parallel to each other, which not only reduce the overall weight but also enhance the stability and rigidity of the structure. The bonding layer uses a high-strength adhesive or adhesive film to firmly bond the surface aluminum panel and the honeycomb aluminum core together to form a whole.

Aluminum sandwich panels are prepared by various methods, including adhesive connection method, laser welding connection method, sewing connection method and so on. Among them, the adhesive connection method is a simple and convenient method, but there are lower strength and easy delamination under high temperature and corrosive conditions to destroy the shortcomings; laser welding connection method is a complex process, the production time is longer; stitching connection method is a complex production process and the strength of the connection is low.

Recommended Products

Recently Viewed

Packaged container houses for export from Tianjin Port, Insulated folding container houses for export

Packaged container houses for export from Tianjin Port, Insulated folding container houses for export Exported container movable houses in Tianjin Port. Wholesale sale of packed container houses and folding container houses

Exported container movable houses in Tianjin Port. Wholesale sale of packed container houses and folding container houses Export rock wool boards from Tianjin Port and export rock wool color steel houses for living

Export rock wool boards from Tianjin Port and export rock wool color steel houses for living Sell color steel houses and prefabricated panel houses. Export container mobile houses for living and office use

Sell color steel houses and prefabricated panel houses. Export container mobile houses for living and office use Color steel prefabricated houses for export to Africa from Tianjin Port, Export container houses

Color steel prefabricated houses for export to Africa from Tianjin Port, Export container houses

Contact Us

Shandong Hark Steel Material Co., Ltd.