Welcome!

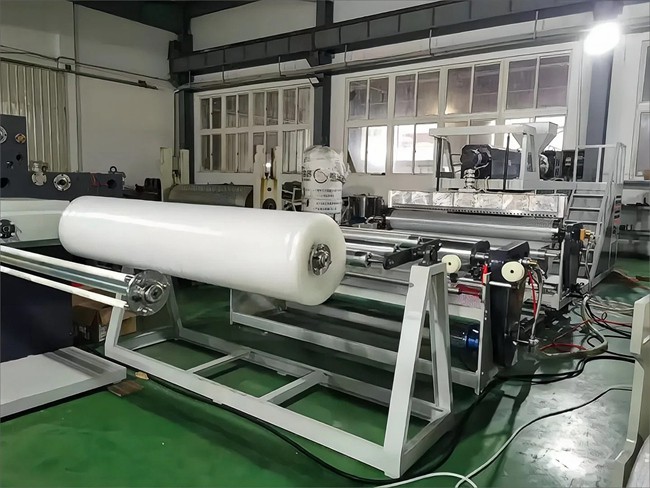

Hot Sale EPE PE CNC Control Pearl Cotton Automatic Feeding and Cutting EPE Foam Cutting Machine

Product Description

EPE foaming machine can adjust the process parameters and mold size according to different production needs, to produce EPE pearl cotton products with different specifications and performance. This flexibility allows EPE foaming machine to adapt to a variety of application scenarios and market changes.EPE pearl cotton as a non-toxic, tasteless, environmentally friendly packaging materials, favored by more and more consumers. And EPE foaming machine adopts environmentally friendly materials and technologies in the production process to ensure that the products meet the relevant environmental standards and health and safety requirements.

The working principle of EPE foaming machine is based on the physical or chemical foaming process of polyethylene material. Inside the machine, polyethylene particles are mixed with foaming agent, catalyst and other auxiliary materials in a certain proportion and then enter the heating system. Under the action of high temperature, the polyethylene particles gradually melt and react with the blowing agent to produce a large number of tiny bubbles. With the expansion and diffusion of the bubbles, the molten polyethylene forms a porous mesh structure, i.e. EPE pearl cotton. Subsequently, the pearl cotton is rapidly cured and shaped by the cooling system, and finally becomes a finished product after cutting and packaging.

EPE foaming machine is mainly used to produce EPE pearl cotton and other foaming materials.EPE foaming machine through a specific physical or chemical foaming method, so that the polyethylene material expansion and the formation of a porous structure, so as to get the excellent cushioning, shock resistance, heat insulation, sound insulation and other properties of the EPE pearl cotton products.EPE foaming machine as a kind of important foaming machinery and equipment in packaging, construction, automotive and other fields play an Important role. With the continuous innovation of technology and market expansion, EPE foaming machine market will continue to maintain rapid development trend.

Features of EPE foaming machine

High efficiency and energy saving: adopting advanced heating and cooling technology, it can effectively reduce energy consumption and improve production efficiency.

Easy to operate: the equipment has a high degree of automation, easy to operate and easy to learn, which can reduce labor costs and labor intensity.

Stable performance: reasonable structural design of the equipment and excellent material selection can ensure the stability and consistency of product quality.

Strong adaptability: according to different production needs to adjust the process parameters, to produce different specifications and performance of EPE pearl cotton products.

Recommended Products

Recently Viewed

High Quality Three Layers PE Air Bubble Film Extruder Machine

High Quality Three Layers PE Air Bubble Film Extruder Machine High Speed Filmplastic Bubble Film Machine for Aluminum Laminating Machine

High Speed Filmplastic Bubble Film Machine for Aluminum Laminating Machine High Speed 3-7 Layers Composite Air Bubble Film Making Machine

High Speed 3-7 Layers Composite Air Bubble Film Making Machine High Quality 3-7 Layers Composite Air Bubble Film Making Machine

High Quality 3-7 Layers Composite Air Bubble Film Making Machine Factory Direct Three Layers PE Air Bubble Film Extruder Machine

Factory Direct Three Layers PE Air Bubble Film Extruder Machine

Contact Us

Zhejiang Benfan Machinery Co., Ltd.