Welcome!

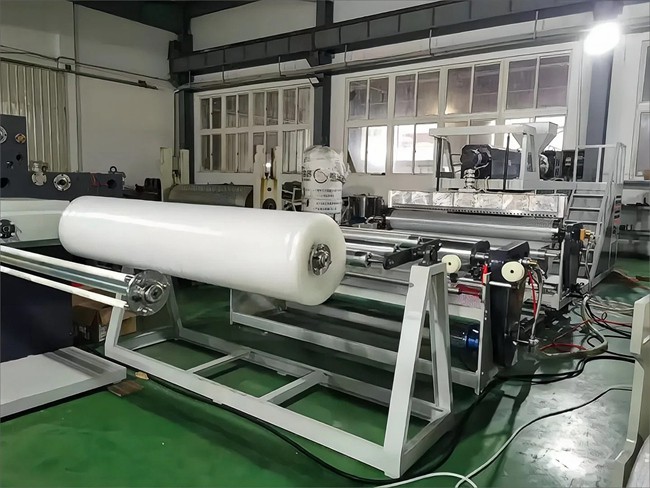

Hot Sale EPE XPE Foam Plank Cutting Machine Vertical and Horizontal Slitting Machine

Product Description

EPE foaming machine is mainly used to produce EPE pearl cotton and other foaming materials.EPE foaming machine through a specific physical or chemical foaming method, so that the polyethylene material expansion and the formation of a porous structure, so as to get the excellent cushioning, shock resistance, heat insulation, sound insulation and other properties of the EPE pearl cotton products.EPE foaming machine as a kind of important foaming machinery and equipment in packaging, construction, automotive and other fields play an Important role. With the continuous innovation of technology and market expansion, EPE foaming machine market will continue to maintain rapid development trend.

Working steps of EPE foaming machine

Raw material preparation: Mix the polyethylene particles with foaming agent and other auxiliary materials in a certain proportion.

Heating and melting: The mixed raw materials are fed into the heating device and heated to the molten state.

Foaming process: In the molten state, introduce gas (such as butane, etc.) through physical or chemical methods to make the polyethylene material expand and form a porous structure.

Cooling: The foamed material is cooled to room temperature to allow it to set and cure.

Cutting and Packing: The cooled and shaped EPE foam will be cut into the required size and packaged as required.

Recommended Products

Recently Viewed

High Quality Three Layers PE Air Bubble Film Extruder Machine

High Quality Three Layers PE Air Bubble Film Extruder Machine High Speed Filmplastic Bubble Film Machine for Aluminum Laminating Machine

High Speed Filmplastic Bubble Film Machine for Aluminum Laminating Machine High Speed 3-7 Layers Composite Air Bubble Film Making Machine

High Speed 3-7 Layers Composite Air Bubble Film Making Machine High Quality 3-7 Layers Composite Air Bubble Film Making Machine

High Quality 3-7 Layers Composite Air Bubble Film Making Machine Factory Direct Three Layers PE Air Bubble Film Extruder Machine

Factory Direct Three Layers PE Air Bubble Film Extruder Machine

Contact Us

Zhejiang Benfan Machinery Co., Ltd.