Welcome!

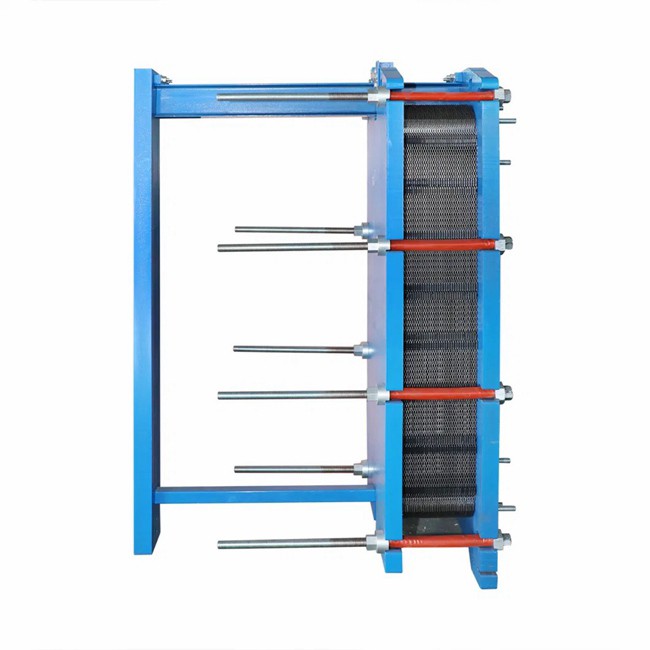

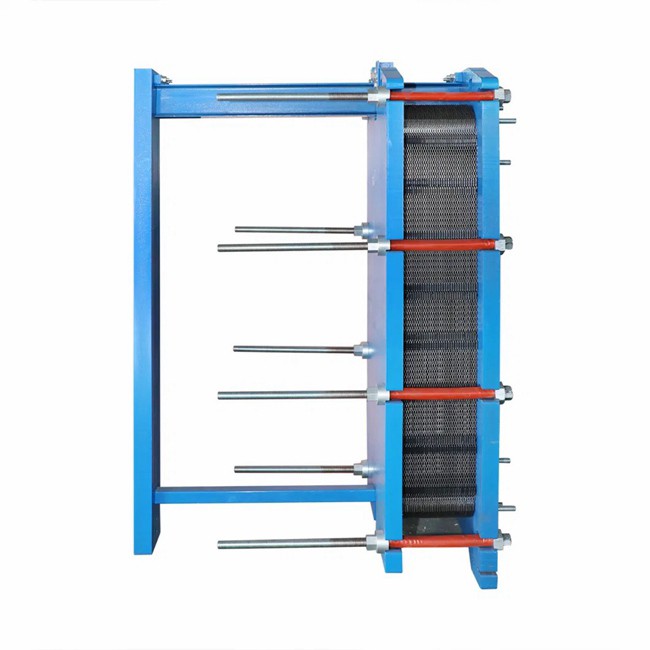

China Factory Heat Exchanger Evaporator Blower Air Dryer Filter Steam Heat Exchanger

Product Description

advantage:

High heat transfer coefficient and high heat transfer efficiency.

Compact structure, large heat exchange area, and small footprint.

High flexibility, the heat exchanger area and number of heat exchange sections can be adjusted according to needs.

Less consumables, easy maintenance and cleaning.

Disadvantages:

The sealing perimeter is long and there is a high chance of leakage.

Due to the limitations of the sealing material, the operating pressure and temperature cannot be too high.

Due to the small spacing between the plates, the flow rate should not be too high and the viscosity of the medium should be low during operation, while there should be no solid particles, otherwise it is easy to block the channels between the plates.

There are various types of heat exchangers in air dryers, including plate fin heat exchangers and shell and tube heat exchangers. Among them, plate fin heat exchangers are widely used due to their compact structure and high heat transfer efficiency. It usually consists of a core, a head, a connecting pipe, and a support, and the core is a key component for completing heat exchange.

Recommended Products

Recently Viewed

Good Quality Air Dryer Exchanger All Famous Brands Replacement Spare Parts Plate Heat Exchangers

Good Quality Air Dryer Exchanger All Famous Brands Replacement Spare Parts Plate Heat Exchangers China Factory Air Dryer Exchanger All Famous Brands Replacement Spare Parts Plate Heat Exchangers

China Factory Air Dryer Exchanger All Famous Brands Replacement Spare Parts Plate Heat Exchangers Cooler,Heat Exchanger,Oil Cooler

Cooler,Heat Exchanger,Oil Cooler Stainless Steel Condenser for Distillation, Cooling, and Heat Recovery Processes

Stainless Steel Condenser for Distillation, Cooling, and Heat Recovery Processes High-Accuracy Air Dryer Exchanger All Famous Brands Replacement Spare Parts Plate Heat Exchangers

High-Accuracy Air Dryer Exchanger All Famous Brands Replacement Spare Parts Plate Heat Exchangers

Contact Us

GUANGDONG Y.K.R NEW ENERGY CO.,LTD.